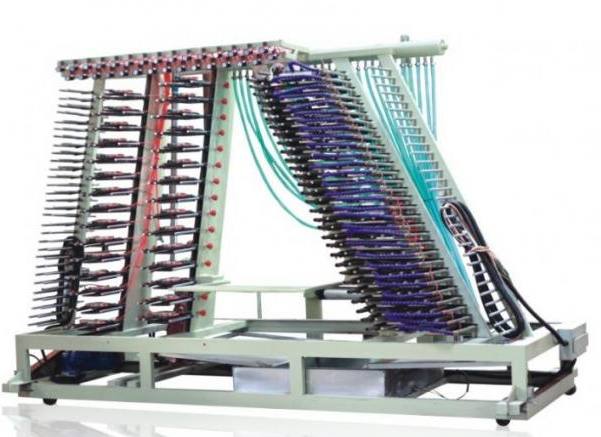

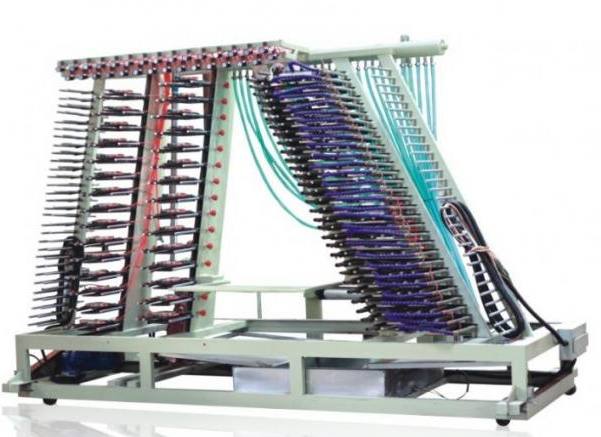

LW-2DNC PLC control paper tube machine, Chinese cheap paper tube

machine

- Applicable Technical Parameters:

| 100-600 GSM |

| 22-65 mm |

| 2-5 mm |

| 1-15 m/min(depends on paper material , making tube’s size and

operator skill) |

| Single circular knife |

| 1000 - 4000mm |

- Machinery Consists Detailed Description:

- Adopt microcomputer to set cutting length, more accurate; Touch

screen is more convenient to adjust data.

- Equipped with specialized human-machine operation interface,

hang-operation panel, more convenient to operate.

- Upload paper mechanically, improve efficiency, reduce labors and

production cost.

- Adopt hang-type operation panel, easy to operate.

- Move glue system and paper unit by motor, convenient and save

labors.

- The tension of paper ply is controlled by the air pressure. The

cylinder presses the paper ply tightly and adjust its tightness

freely

- Supply 10 layers of paper & glue box and air pressure tension

control, can adopt single side or double side gluing according to

compressive strength of paper cores.

- The machine can alarm automatically and stop when bottom-ply

breaks. Avoid the trouble that glue sticking on the winding shaft.

- Paper core cutting in line is controlled by the servo motor, can

track winding speed to realize synchronization.

- Glue stand can be moved forward and backward, left and right,

drived by special motor.

- .Paper Reel stand can be moved, left and right, drived by special

motor.

- Glue stand can control glue temperature by heating device.

- Tension plate install in paper reel stand using ceramic pressing

plate, long life time.

- Main power 5.5 KW(Frequency conversion)

- Mandrel 1 pcs (depend on customer’s requirement)

- Winding belt 1 pcs (depend on customer’s requirement)

- Belt tightness device hand-wheel

- PLC Siemens

- Paper stand 10 plies, attached hoist in the paper stand, load paper

reels

easily.

- Glue transporting mode transport by pneumatic diaphragm pump

automatic

- Paper/glue Stand Movement 0.75KW motor(angle adjustment)

- Glue transporting pipe 10 plies (include glue collecting tank)

- Glue stand glue 10 paper plies, control by air pressure

- Surface-ply paper stand 1 set (drum roller type)

- Bottom-ply paper stand 1 set

- Paper tube collecting device 1 set

- Bottom-ply length calculate encoder (Omron)

- Knife driving motor Yaskawa, Japan

- Length control PLC set the length in touch screen(Weinview)

- Counter 1 set (can count paper core quality)

- Pendant Type operation box: 1 set

- Separate electric box: 1 set

- Auto alarm system 1 set (when bottom-ply breaks, auto alarm and

stop)

- Paper Reel Angle adjust system 1 set

- Main Machinery Parts Material and Instruction:

- Moulds are made of carbon steel by lathe worker, hardening and

surface coated hard chrome.

- Winding belt made by durable canvas material.

- All rolling wheel made by seamless steel pipe, by hardening

process.

- Main structure made by iron casting material, by teeming work. With

stable structure, good absorption capability. Reduce mechanical

vibration.

- Sparaparts list and special tools:

- Winder Belt 1 PCS

- Blade 1 PCS

- Relay 1 PCS

- Proximity switch 2 PCS

- Choice switch 2 PCS

- Button switch 2 PCS

The main function

Microcomputer length setting, cut length is accurate; touch the

screen to facilitate data adjustment.

With human-machine interface and dedicated operating system, the

hanging operation panel is easier to operate.

Electric paper increases efficiency, reducing production personnel

and reducing production costs.

The movement of the paper holder and the gluing system is performed

by a motor, which is convenient and labor-saving.

The tension control of the paper strip is made by the air pressure

system. The tightness of the cylinder pressure paper strip can be

adjusted freely.

For glue on 10 pieces of paper containing plastic boxes and

pneumatic tension control, can be based on the strength of paper

tubes

Double sided or single sided paper.

The paper break of the bottom sheet can be automatically alarmed

and shut down. It is very difficult to remove the white glue on the

roll bar.

The movement speed of the paper tube cutting section is controlled

by a servo motor, which can track the production speed of the paper

tube to achieve synchronization.

The paper system, the glue system and the host unit, can realize

electric left, right, front and back movements

Plastic frame with heating function