Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Fruit Sterilizer Pasteurization Apple Pear Processing Equipment Multiple Application

Company Information

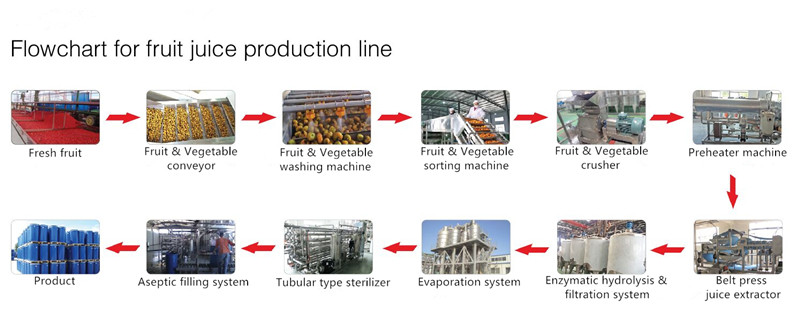

Gofun Company provides the turn-key solution for not only the tomato paste production line but also the processing and packaging lines for apple, pear, peach, mango, and apricot and other fruits & vegetables, and has received wide spread praises from customers in both the domestic and overseas markets. The machines have already been exported to all over the world including the Asian countries, African countries, South American countries and even European and American countries. Gofun Company aim to create the outstanding food machinery and contribute to the world's agricultural industry. We sincerely committed ourselves to a brilliant prospect and mutual benefit relationship with all of the people and friends from Worldwide!

Application

Shanghai Gofun machinery company offers all kinds of sterilization processing line. The sterilization way can be tubular type sterilizer, tube in tube type sterilizer or others. The package can be aseptic bags, sachet, stand-up pouch, metal can, PP container, PET bottle, glass bottle, gable top, etc. Shanghai Gofun machinery company can help you produce all kinds of fruit and vegetable products.

The capacity of fruit and vegetable sterilizer processing line is varied from 20 T/day to 1500 T/day. The line can also be shared for processing other fruits with similar characteristics. Tube in Tube type sterilizer is specially used and the whole sterilization last only 30 seconds, which allows to maintain products freshness. The sterilization rate is especially no less than 75%. The end products are of good taste and nice color. Multi-effect evaporator can be chosen for different capacity. Either fully automatic line or semi-automatic line can be chosen according to the cost.

Description

The sterilizing temperature and holding time is adjustable.With this machine, the fruit or vegetable juice/paste/pulper can be heated to a very high temperature around 115℃, held for 30s and then cooled to ambient temperature immediately. UHT sterilizer can protect the taste and nutrients of fruits or vegetables as much as possible.

| Model | GFM10D1000 | GFM10D3000 | GFM10D5000 | GFM10D8000 |

| capacity(L/H) | 1000 | 3000 | 5000 | 8000 |

| power(KW) | 15 | 25 | 40 | 72 |

| System design pressure(MPa) | 4 | 5 | 10 | 16 |

| Steam consumption(kg/h) | 250 | 750 | 1300 | 2000 |

| Compressed air consumption(m³/h) | 12 | 12 | 12 | 12 |

| Cooling water consumption(t/h) | 15 | 25 | 45 | 70 |

| Material sterilization temperature(℃) | 90-125 | 90-125 | 90-125 | 90-125 |

| Sterilization time(s) | 120-180 | 120-180 | 120-180 | 120-180 |

| Feed temperature(℃) | 60-68 | 60-68 | 60-68 | 60-68 |

| Discharge temperature(℃) | ≤40 | ≤40 | ≤40 | ≤40 |

| Exterior dimension(mm) | 9500X2100X3000 | 1100X2100X3000 | 1200X2400X3000 | 1300X2500X3000 |

Principle

Advantages