Shanghai Gofun Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Pasteurizer for dairy milk product complete milk processing line low consumption

Company Information

Gofun is the professional manufacturer in China with 16 years experience. Our main business includes:

We offer a comprehensive range of fruit and vegetable separation equipment to support various processing stages. This includes equipment for cleaning, sorting, crushing, pulping, refining, evaporation, sterilization, filling, packaging, pasteurization, high-pressure processing (HPP), and more.

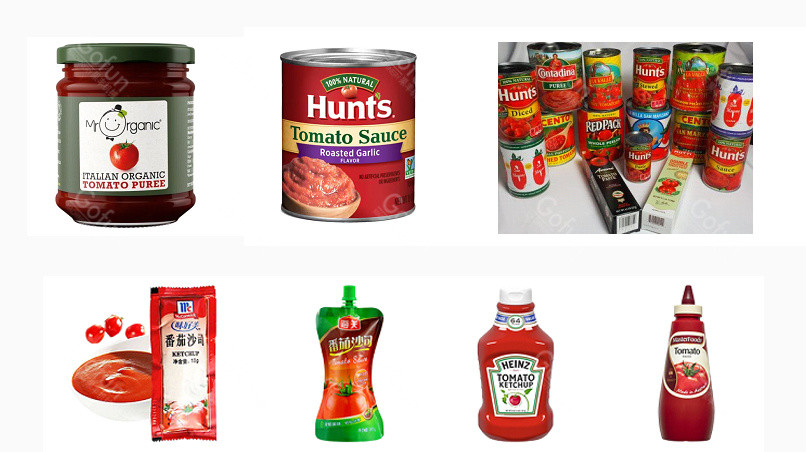

Our expertise extends to providing complete fruit processing plants tailored to specific needs. We specialize in designing and delivering processing plants for various fruits, including tomato, tropical fruits like mango, pineapple, guava, passion fruit, papaya, as well as common fruits like strawberry, apple, pear, peach, apricot, and more.

Our offerings include complete filling line solutions for a wide range of packaging formats. Whether it's aseptic bags, metal cans, sachets, stand-up pouches, PP containers, glass bottles, PET bottles, gable tops, or other packaging options, we can provide the entire plant setup to meet your packaging requirements.

The sterilization temperature and holding time of the machine are flexible and can be adjusted according to requirements. Using this equipment, fruit and vegetable juice, pulp, and fruit puree can be heated to a high temperature of approximately 115°C, held for 30 seconds, and rapidly cooled down to ambient temperature. The UHT (Ultra-High Temperature) sterilizers employed in the process effectively preserve the flavor and nutrients of fruits and vegetables, ensuring that they are retained to the maximum extent possible.

| Model | GFM10D1000 | GFM10D3000 | GFM10D5000 | GFM10D8000 |

| capacity(L/H) | 1000 | 3000 | 5000 | 8000 |

| power(KW) | 15 | 25 | 40 | 72 |

| System design pressure(MPa) | 4 | 5 | 10 | 16 |

| Steam consumption(kg/h) | 250 | 750 | 1300 | 2000 |

| Compressed air consumption(m³/h) | 12 | 12 | 12 | 12 |

| Cooling water consumption(t/h) | 15 | 25 | 45 | 70 |

| Material sterilization temperature(℃) | 90-125 | 90-125 | 90-125 | 90-125 |

| Sterilization time(s) | 120-180 | 120-180 | 120-180 | 120-180 |

| Feed temperature(℃) | 60-68 | 60-68 | 60-68 | 60-68 |

| Discharge temperature(℃) | ≤40 | ≤40 | ≤40 | ≤40 |

| Exterior dimension(mm) | 9500X2100X3000 | 1100X2100X3000 | 1200X2400X3000 | 1300X2500X3000 |

Shanghai Gofun Machinery Company specializes in providing a comprehensive range of sterilization processing lines for a variety of fruit and vegetable products. Our sterilization methods include tubular type sterilizers, tube-in-tube type sterilizers, and other suitable techniques to ensure the highest standards of food safety.

Our sterilization processing lines offer versatile packaging options to meet the diverse needs of our customers. These options include aseptic bags, sachets, stand-up pouches, metal cans, PP containers, PET bottles, glass bottles, gable tops, and more. We understand the importance of packaging in preserving the quality and extending the shelf life of fruit and vegetable products.

Our fruit and vegetable sterilization processing lines have a flexible production capacity range, ranging from 20 tons per day to 1500 tons per day. In addition, the production line can also be customized to process other fruits with similar characteristics according to customer needs. One of the features we are proud of is the tube-in-tube sterilizer, which completes the entire sterilization process in as little as 30 seconds. This rapid sterilization process helps preserve the freshness, flavor and attractive color of the product.

We promise that the sterilization rate will not be less than 75% to ensure that the final product has excellent taste and quality. Whether a customer requires a fully automatic or semi-automatic production line, we have options to suit different budgets and production requirements. In addition, for optimal performance, production lines in different capacity ranges have the option of integrating multi-effect evaporators into them.

At Shanghai Gofun Machinery Company, we are committed to providing high-quality sterilization processing lines that meet the stringent standards of the fruit and vegetable processing industry. Our expertise, advanced technology, and dedication to customer satisfaction make us a reliable partner for your sterilization needs.

| Main configuration of the system | ||

| No. | Item | Brand |

| 1 | PLC | Siemens |

| 2 | Human Machine Interface | Siemens |

| 3 | Steam Reducing Valve | Spirax Sarco |

| 4 | Steam Regulating Valve | Spirax Sarco |

| 5 | Steam Trap Valve | Spirax Sarco |

| 6 | Electric Elements | Schneider |

| 7 | Transducer | Japan Fujifilm |

| 8 | Temperature paperless recorder | YOKOGAWA |

| 9 | Breaker | Schneider |

| 10 | Central relay | Omron |

Principle

Within the sterilization system, the product is transferred from the storage tank to the heat exchanger unit. Superheated water is used to heat the product to the desired sterilization temperature. During this process, the products are carefully kept below sterilization temperatures to ensure their quality and safety. The product is then cooled to filling temperature by using cooling or chilled water, depending on the specific needs.

Before the start of each production shift, the entire system, including the aseptic filling machine, undergoes a thorough sterilization process with ultra-hot water. This "sterilization in place" procedure ensures that the system is free of any potential contaminants to ensure production safety and hygiene.

At the end of each production shift, the system and aseptic filling machines are cleaned in place to maintain optimal cleanliness and prevent cross-contamination. This cleaning process involves the use of hot water, lye and acid to effectively remove any residue or impurities that have accumulated during the production process.

By implementing these measures, we ensure that our sterilization systems and filling machines are always in hygienic condition and comply with the highest food safety and quality standards.

Advantages

1. High-tech enterprise with our own professionally team and manufactured factory.

2. The advanced technology is at the leading level at home and abroad, and has obtained technical patents.

3. Location in national key high-tech zone, only 30mins to airport.

4. Strict quality inspection, all products are advanced and durable with high reputation.

5. Good pre-sales and after-sales service.