Zhangjiagang Friend Machinery Co., Ltd. |

|

Verified Suppliers

|

|

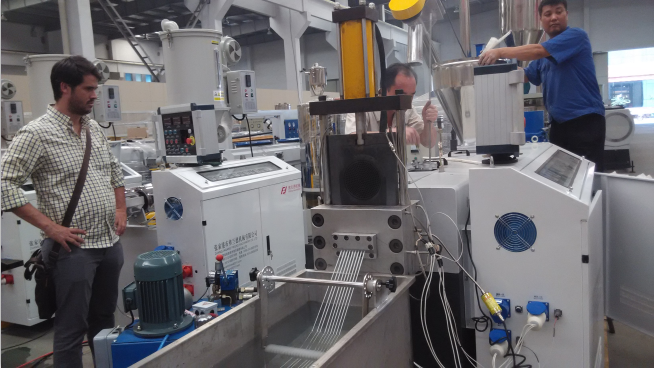

SJ65 HDPE LDPE PP Film Cold Strand Pelletizing Granulating System

Introduction

* This SJ65 HDPE LDPE PP Film Cold Strand Pelletizing Granulating System is designed and manufactured by Friend Machinery, which is widely

used for waste plastic PE PP soft material, such as clean HDPE,

LDPE, LLDPE film flakes, clean PP woven bag, etc.

* The material go through compressing system, plasticizing

system,water cooling system, pelletizing system and collect

system will turn to be clean perfect pellets for reuse.

* You can choose twin stages or single stage extruder according to

the cleanliness of your material condition and capacity

requirements.

* This plastic pelletizing line can be displayed "L" or "U" shape

according to clients' workshop size .

* We also provide plastic crushing washing recycling line to get

clean dry flakes or film from dirty waste material.

* We can also customize the pelletizing line according to client's

material and product requirement.

* Working Flow (Strand-Cooling Cutting Pelletizing Line)

* Features

1. Automatically working, conveying material, plasticizing,

extruding, cooling, drying, cutting, collecting.

2. High efficiency, safety control, capacity from 150-1000 kg/h.

* Processing

Worker put film or bag into Agglomerator---------plastic ball---------screw loader feeds plastic into extruder

hopper----------extruder plasticizing process( vent screw )---------Hydraulic network(for impurity sorting)-----

----Mold ( for 3mm diameter pellet ) ---------water bath cooling--------forcecoolingfan ( for cooling and

water blowing )---------pelletizer (could adjust pellet length by adjusting cutting speed )---------Vibrating

Screen ( for sorting good quality and size pellet )

---- Compactor: With multi blades crushing and compulsively compress the film into extruder.

---- Single Screw Extruder : Plasticizing material with high

temperature and exhausting hot gas.

---- Hydraulic Screen Exchanger: Filter material impurity to make

production more stable.

---- Die Mold: Materials come out in long strand.

---- Water Cooling Tank: Cooling the strap with cold water.

---- Force Air Drying System: Drying the strand.

---- Pelletizer Cutter: Cutting the strap into pellets with high

speed rotation.

---- Vibration Screen: Pick out bad pellets and keep good pellets.

---- Air Blower: Blower push pellets into the silo.

---- Storage Silo: Collecting pellets, made by high quality

stainless steel

---- Control Cabinet: Control the whole line on/off (adopt famous

brand such as Schneider, Siemens, etc.)

* Technical Parameter

| Model | Screw Diameter | Screw L/D | Main Motor Power | Capacity |

| SJ65 | 65mm | 30:1 | 37kw | 80-100KG/h |

| SJ85 | 85mm | 30:1 | 55kw | 150-200kg/h |

| SJ100 | 100mm | 30:1 | 75kw | 200-300 kg/h |

| SJ130 | 130mm | 30:1 | 90-110kw | 300-400 kg/h |

| SJ150 | 150mm | 25-35:1 | 110-132kw | 400-500 kg/h. |

| SJ160 | 160mm | 25-35:1 | 132-160kw | 600-800 kg/h |

| SJ180 | 180mm | 25-35:1 | 160-200kw | 800-1000 kg/h |

Clause & Service:

Installation and Debugging:

Pre-sale: we given client the details technician offer, sign the

sales contract etc.

In-sales: we supply the details layout, installation instruction,

technician support for the clients.

After sales: we arrange engineer to install the machinery and

training the workers for client. We always up date the new

technology to every customer.

Delivery and Shipping:

After the contract comes into effect, buyer pay deposit, we will start to produce. When all the machines are completed, buyers come to factory to observe and test machine by themselves, until all the machines are satisfied with the buyers, they can pay for the other balance. Our company arrange to shipping goods to buyer. We provide the goods to be shipped by air or by sea. Pictures of cargo loading will be sent to every client to check and keep recording.

Package:

Packing with film, pallet or wooden case.(according to customers' request).

Guarantee:

We provide one-year warranty guarantee for all the machines. We supply long term spare parts for every customer.

Certificate: CE, ISO9001.2008.