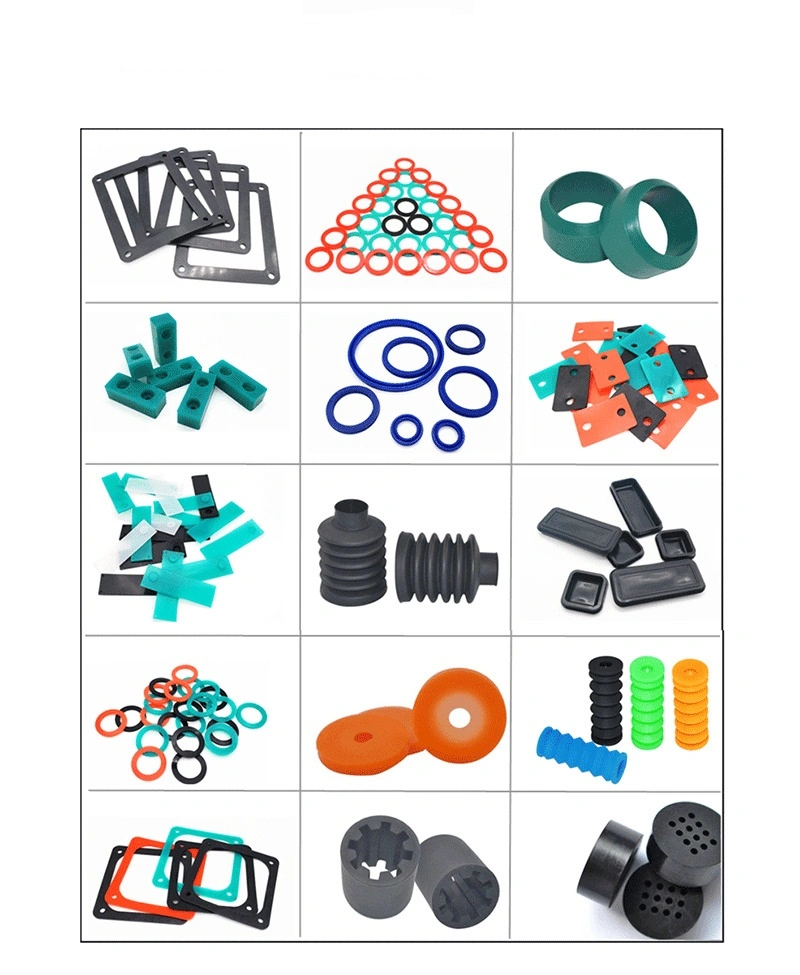

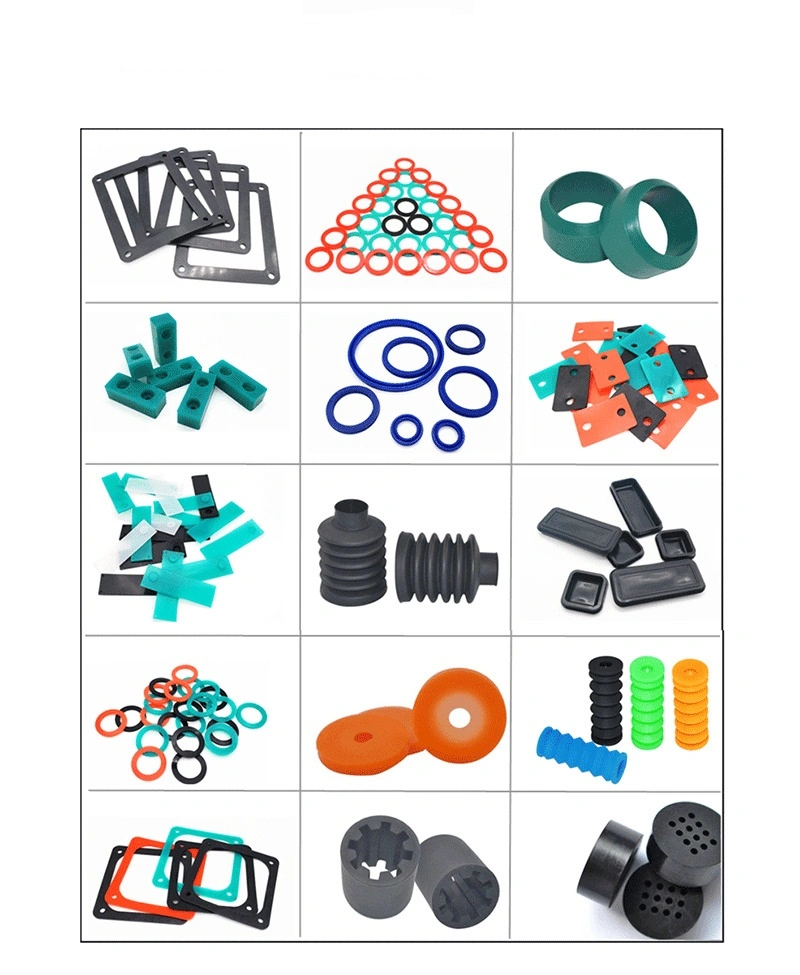

Production Description

| Item Name | Molded rubber part |

| Material | Silicone, EPDM, PVC, TPE, ,Neoprene, etc |

| Color | Black, white or as client's requirement |

| Hardness | 30~90ShA |

| Dimension | As client's requirement |

| Temperature range | ~50 to 380ºC |

| Function | Sealing ,waterproof,dust proof, anti-slip, vibration resistant |

| Application | Medical industry, machinery industry, automotive industry, etc |

| Process | Molding or Injection |

| Certification | SGS, ROHS, REACH, FDA, etc |

| OEM | Welcome to customized |

Plastic Injection Mould making

Plastic Injection Mould making1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with

you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling

processing.

6.Mould testing:We will inform you the date.Than will send the

sample's inspection report&injection parameters with the sample

to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow

mould, silicone mould, die casting mould service.

Plastic molding Specification1. Professional manufacturer,design,production injection mould and

stamping mould quality control

2. rich export experience plastic injection mould and stamping

mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available

Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

The property and advantage of rubber gasket1.smooth surface without any burr2.super sealing performance, for blocking water, wind, dust, noise

outside3.Weather resistant(Ozone, UV, freezing cold, sunlight)4.excellent flexibility and anti-deformation5.Widely temperature range(~40~300ºC)6.Chemical and water resistance The property of various of material for Rubber gasket is as below,1. the property of NRIt has good wear resistance, high elasticity, breaking strength and

elongation, But in the air, it is easy to get age, and it is get

sticky when it get in touch with heat, which is easy to expand and

dissolve in mineral oil or gasoline, but it is resistant to strong

acid, but not to Alkali . working temperature is -50~70ºC.2. the property of EPDMWeather ability, aging resistance, ozone resistance, chemical stability are

excellent, and CFCS and a variety of refrigerants. Working temperature is -50~1503. the property of siliconeIt has excellent heat resistance, cold resistance, ozone resistance

and atmospheric aging resistant.Good electrical insulation performance,The tensile

strength and wear resistance are generally poor and has non- oil

resistant. The working temperature is -55~250ºC4. The property of NBRGood oil resistance, heat resistance, abrasion resistance, solvent

resistance and high - pressure oil,But it is not suitable for polar solvents, such as ketones, ozone,

nitro-hydrocarbons, and chloroform. The working temperature is -40~120 ºC5. the property of CRIt has good elasticity, wear resistance and atmospheric aging

resistance. It is not afraid of violent distortion and flammability.Chemical stability. The working temperature is -40~100 ºC6. The property of FKMExcellent high temperature resistance,And have excellent chemical resistance, most oil and solvent

(other than ketones and esters).cold resistance is not good.6. The property of PUHigh strength, excellent wear resistance, good oil resistance and

solvent resistance,,In particular, it has good anti-swelling

properties for lubricating oil and fuel oil,Good ozone resistance.

But it's not high temperature. The working temperature is -45~110 ºC.

The property of various of material for Rubber gasket is as below,1. the property of NRIt has good wear resistance, high elasticity, breaking strength and

elongation, But in the air, it is easy to get age, and it is get

sticky when it get in touch with heat, which is easy to expand and

dissolve in mineral oil or gasoline, but it is resistant to strong

acid, but not to Alkali . working temperature is -50~70ºC.2. the property of EPDMWeather ability, aging resistance, ozone resistance, chemical stability are

excellent, and CFCS and a variety of refrigerants. Working temperature is -50~1503. the property of siliconeIt has excellent heat resistance, cold resistance, ozone resistance

and atmospheric aging resistant.Good electrical insulation performance,The tensile

strength and wear resistance are generally poor and has non- oil

resistant. The working temperature is -55~250ºC4. The property of NBRGood oil resistance, heat resistance, abrasion resistance, solvent

resistance and high - pressure oil,But it is not suitable for polar solvents, such as ketones, ozone,

nitro-hydrocarbons, and chloroform. The working temperature is -40~120 ºC5. the property of CRIt has good elasticity, wear resistance and atmospheric aging

resistance. It is not afraid of violent distortion and flammability.Chemical stability. The working temperature is -40~100 ºC6. The property of FKMExcellent high temperature resistance,And have excellent chemical resistance, most oil and solvent

(other than ketones and esters).cold resistance is not good.6. The property of PUHigh strength, excellent wear resistance, good oil resistance and

solvent resistance,,In particular, it has good anti-swelling

properties for lubricating oil and fuel oil,Good ozone resistance.

But it's not high temperature. The working temperature is -45~110 ºC.