Xinghe Roll Forming Machinery Co.,Ltd |

|

Full Automatic EPS And Rock Wool Sandwich Roofing Production Line,EPS Sandwich Panel Machine

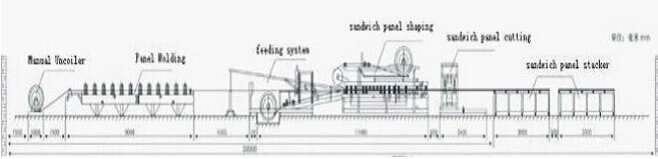

Working drawing

Sandwich roof machine details

| No. | Main parameter of Sandwich panel forming machine line | ||

| 1 | Suitable to process | Color steel plate | |

| 2 | Width of the plate | 1000&1200mm | |

| 3 | Rollers | 17-44rows | |

| 4 | Dimensions | 20.0*2.25*2.5m | |

| 5 | Power | 30kw | |

| 6 | Thickness of the plate | 0.3-0.8mm | |

| 7 | Productivity | 2-6m/min | |

| 8 | Diameter of the roller | Φ90mm | |

| 9 | Weight | About 15 T | |

| 10 | Voltage | 380V 50Hz 3phases | |

| 11 | Material of the cutting plate | Cr12 | |

| 12 | Processing precision | Within 1.00mm | |

| 13 | Control system | PLC control | |

Sandwich panel machine line technical parameters

Sandwich panel standards | |

| Length | Min cut length: 3 m Max stacker length: 15 m |

Raw material standards | |

| Coil thickness | 0.4~0.6mm (the coil surface should be flat, no arch and the others surface trouble.) |

| Material coil yield strength | 235MPa |

| Material coil max width | see detailed profile drawings. |

| Material coil max weight | 5 T |

| Material coil inner diameter | Φ508,Φ610 mm |

EPS core material | |

| density | ≥18Kg/m3 |

| straight rate | ≤1mm/m |

| arch degree | ≤3mm/m |

| panel surface | shoule be flat no flat degree is ≤1.5mm/m, |

| sandwich panel length | longer than 5 meters |

Main parameters

| No. | main parameter of roll forming machine | ||

| 1 | suitable material | Color Steel plate, galvanized sheet | |

2

| Width of the plate | 1200mm | |

| effective surface | 950/960/970/980mm | ||

| 3 | Rows of rollers | 14 rows | |

| 4 | Size | 7.5*1.3*1.2m | |

| 5 | Total power | 4kw | |

| 6 | Thickness of raw material | 0.3-0.8mm | |

| 7 | Productivity | 8-10m/min | |

| 8 | diameter of shaft | 80mm | |

| 9 | Weight | About 4T | |

| 10 | Voltage | 380V 50Hz 3phases | |

Payment term and condition

| 1 | Payment Term | 30% T/T in advance, 70% T/T before shipment |

| 2 | Delivery Time | Within 60 Working Days after receipt of the down payment |

| 3 | Warranty | 1 year and life-long maintenance |

| 4 | Installation and commissioning | Our engineer will go to make installation there, Buyer pay our engineer 100 USD /day, an |

Machine shows