GUANGDONG SHANAN TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

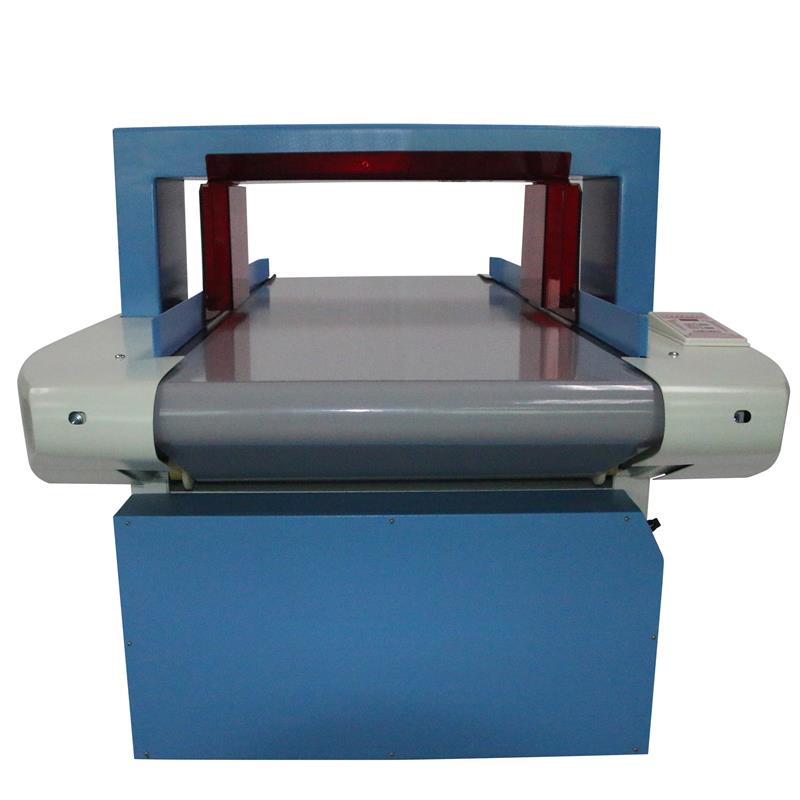

Textile Industry Needle Detector / Walmart FCCA Audit Needle

Detector / FCCA Audit Metal Detector

To make sure that all garments manufacturing unit are free of any

broken needle or other metal parts which could cause injury to a

person handling the product at any stage of the operation.

All garments that need to be checked for metal is passed through

metal detecting machine in the finishing department and else where

as maybe applicable.

Finishing Manager will ensure that all garments that are required

to undergo metal detection is checked for metal and the Manager QA

must ensure that the work is conducted adequately and at all times.

Needle and Metal Contamination Policy

Needle and Metal Contamination Policy ensures that all its products

are free of any broken needle or unwanted sharp metal parts. The

Needle and Metal Contamination Policy is divided into two phases:

1.1 Prevention

1.2 Detection

1.1 Prevention:

Broken Needle Control Log Procedure is applicable to produce Target

products where needle operations are involved.

roken Needle Log Control Procedure:

Every factory that uses any type of needle operation, regardless of

product, is required to comply with the Broken Needle Control Log

procedure.

• The Broken Needle Control Log should include:

o Date/Time of Incident

o Production Line

o Operation

o Operator

o Machine Type/Machine ID

o Mount Broken Needle

o Panel/Garment Destroyed – Yes or No

o Mechanic‘s signature and Date

• Every factory must maintain a controlled needle inventory system

and a broken needle control log.

• This log should include all broken parts or damaged needles along

with any corrective action taken.

• Each sewing machine should have an ID (identification number).

• Needle replacement should be done only by designated factory

personnel (e.g. inline supervisor, mechanic, needle log supervisor,

etc.) to provide a log recording all parts of a broken needle have

been accounted for.

• Note: Sewing operator should not have free access to spare

needles.

• Production work areas are to be kept clear of unnecessary sharps

(e.g. scissors, razor blades, staples, pins and loose metal parts).

• Machines and/or operators which continue to have broken needle

issues should be reviewed and appropriate corrective action taken.

• Machines and their surrounding areas should be checked daily for

needle and/or metal contamination.

• For products where a needle/metal detector is mandatory

• In the event of a needle breaking during any sewing operation,

the panel or product piece being sewn should be retrieved from the

production line and checked for broken parts.

• Broken parts should be sealed on the broken needle log control

sheet indicating all details listed above.

• If all broken parts are not accounted for, contaminated panels or

product pieces should be passed through the needle detector. If the

needle detector still detects metal parts and if after further

investigation, the pieces cannot be found, the panel or product

pieces should be destroyed and recorded on the log.

Factory product safety officer must check if Needle and Metal

Contamination Policy is being followed by checking:

• Needle Inventory System

• Broken Needle control log for accuracy and integrity of the

records.

• Sewing machines have ID number and are verified against the

Needle Inventory System and Broken Needle control log.

• Check machine oil sump for any broken parts and surroundings for

loose metal parts.

• Check that sewing operator does not have access to needles and

unnecessary sharps by verifying machine surrounding and drawers.

Features:

Mechanism exported from Japan, conveyor belt exported from Holland,

non-toxic, new coil technology, computer chip integration adopt

digital circuit.

Specially has the protection circuit, it will auto-stop if no

detection goods in 10 minutes, Ad Hoc lightning protection circuit

leak.

All the function keys are touching-type keys,8 locations can

display the accurate position of broken needle

3 ways to alarm: sound, light, and frequency

Open all of the features set the total power; the motor does not

start before the completion of.

Can calculate the qualified and unqualified and unqualified amount

It has two sets of detectors, double testing to ensure results

Strong anti-disturbance (no wrong alarm to the ceiling fan, mobile

phones, screwdrivers, etc )

Pipelined appearance, ABS shell, steel structure, first-class

baking process, to ensure the detection of the machine stability

,good performance, long service life.

| Model | VFG-600K |

| Detection method | Magnet filed induction .digital circuit |

| Dedection ability | ferrous 0.6mm 0.8mm 1.0mm 1.2mm 1.5mm |

| Detection height | 100mm.120mm 150mm 200mm |

| Detection width | 600mm or customized |

| Detection adjustment | touch button adjustment from 1-12 level |

| alarm method | sound light alarm and return then restart again |

| power suply | 220V 50-60HZ |

| pated otput | 110W |

| machine size | 190*110(W)*130cm |

| weight | 200KG |

MODEL | VFG-600K | ||||

Detection method | Magnetic induction.digital process | ||||

Detection ability | ≥FeΦ0.8 | ≥FeΦ0.8 | ≥FeΦ1.0 | ≥FeΦ1.2 | ≥FeΦ1.5 |

Detection Height | 100mm | 120mm | 150mm | 200mm | 250mm |

Detection width | Net width 600mm-non-standard sizes(custom) | ||||

Detection adjustment | Touch screen adjust the level 1-12 | ||||

Alarm method | Sound/light alarm and return, then restarts again | ||||

Power supply | Ac220V 50-60Hz | ||||

Pated output | 140W | ||||

Machine Size | L1820mm×W1050mm×H900mm | ||||

Weight | 280KG | ||||

Vfinder is a manufacturing company specialized in the design, engineering and

production of Metal Detectors .check weigher .needle detector and Electromagnetic Inspection Devices.we offering solution for food industry ,Pharmaceutical industry ,

Textile garment industry ,Rubber industry .Tory industry where the

factory need help to control their quality for find broken needles

and metals .

Under our solution and machine support our valued customer can accreditation with the FDA ,ISF ,HACCP even FCCA request and

requirement .

Meanwhile we strongly support the all the world public security career.with our support by our product of walk through metal

detector and x ray baggage scanner . So many public can be safety ,

so many dangerous products can been keep away from public people .