Ji nan keysong machinery co.LTD |

|

Pellet Animal Feed Processing Machinery 250kg/h For Pig And Cow

Automatic Animal Feed Pellet Machinery

Quick Details

Type | Animal Feed Machine | Voltage: | 380V/400V/415V | Power(W): | 185/200(kw) |

Dimension(L*W*H): | 2800*1150*1730 | Weight: | 4500kg | Certification: | CE & ISO |

Warranty: | 1 Years | After-sales Service Provided: | Engineers available to service machinery overseas | Motor: | Siemens |

Bearing: | SKF or NSK | Technology: | CPM | Capacity: | 8-25(T/H) |

Working temperature of die(℃): | ≤85℃ | Working pressure of steam(Mpa): | 0.2-0.4Mpa | Volume of steam (t/h): | ≥1.5t/h |

Temperature of steam(℃): | 130-150℃ | Material of ring die: | Stainless steel | Application: | poultry animal feed pellet machine |

Introduction:

After a foreign investigation of existing feed pellet machine , taking into account the different requirements of pellet feed, especially

considering the high-pressure hardness and large density features of feed, we design and manufacture this ring membrane feed pellet machine.

Application:

This model has a simple structure, which can be widely applied in small and middle scale aquaculture, grain feed processing plants,

livestock farms, poultry farms and individual farmers.

1. This machine is also applicable to feed factory with an annual output of 1000 to 2000 tons. At present, it is the ideal granulating

equipment in China's feed processing industry;

2. Specializing in the production of feed equipment of various animals, such as pig, cattle, sheep, fish, chicken, goose and duck.

Working Principle:

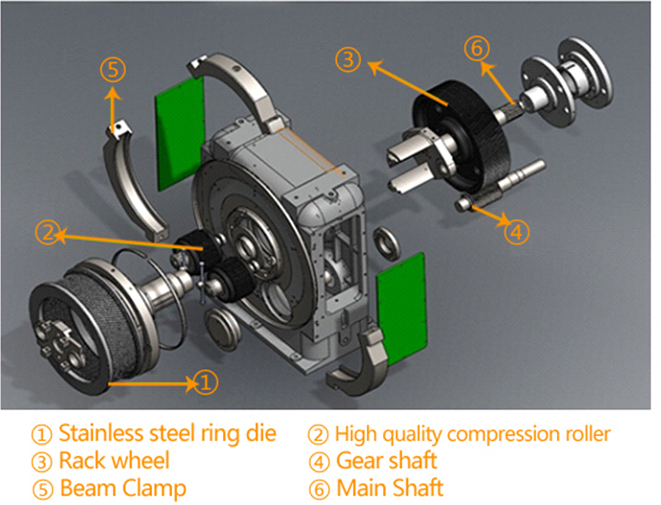

Driven by the motor, the belt drives circular mold, the roller rotates under the action of friction; All kinds of materials, through the

gelatinization and high temperature, expel from the circular mold hole under the extrusion.

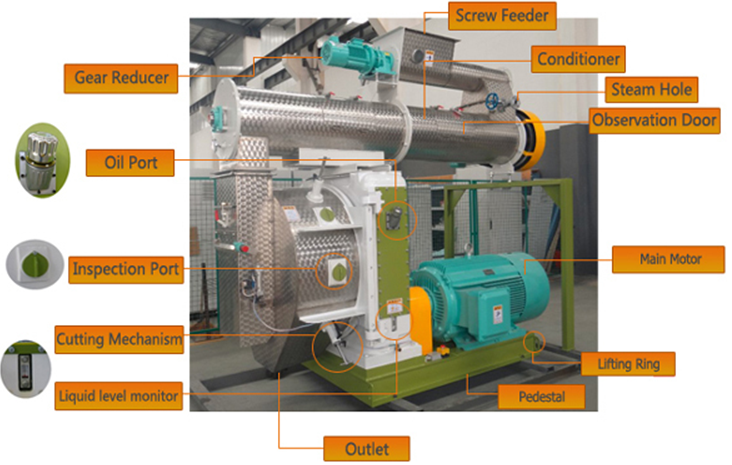

Screw Feeder:

( adjust the feeding speed with inverter)

Stainless Steel conditioner:

( sofiten and even material, adjust moisture content, increase capacity and also improve the appearance of pellets, promote the curing and evenness of pellets etc)

Advantages:

1. Using the triangle belt transmission, simple repair, low noise;

2. The compression die and roller is made of special material, with a special heat process, high quality, long service life and good

effect;

3. The roll and die type particle granulation, high hardness, wide scope of application, the particle size is adjustable, convenient to install or remove roller and die.

heep, fish, chicken, goose and duck.

Feed Features:

1. The feed processed by this machine has moderate temperature, can keep well a variety of trace elements in raw materials, good palatability, large animal intake, which is conducive to digestion and absorption of nutrients.

2. Uniform particles, regular shape and smooth surface, the diameter can transform between 1.5-6mm (need to replace the mold), the length can be adjusted between 5-20mm, and the particle density is easy for storage and transportation, suitable for all kinds of breeding objects in

different growth period.

3. This feed machine has wide adaptability of materials, can process a variety of feeds with different requirements.

4. The processed fish feed can be kept in the water for a long time, improve the utilization rate of feed. Conducive

to the prevention of water pollution.

5. this model can process not only mash feed with low moisture content, but also fresh feed with high water

content.

Technical Parameters:

Model | Power(kw) | Output(T/h) | Pellet Size(mm) | Dimension(mm) |

KS-65 | 22 | 0.6-1.5 | 1.5-12 | 1350*1150*1250 |

KS-70 | 45 | 1.5-2.5 | 1.5-12 | 1600*1350*2250 |

KS-85 | 55 | 3-5 | 1.5-12 | 2400*1900*2100 |

KS-90 | 45 | 4-8 | 2-12 | 1600*2200*2250 |

KS-95 | 75 | 6-12 | 2-12 | 2350*2200*2250 |

After-sale services:

Provide considerate services to minimize clients’ worries.

(1) Assist clients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(4) Examine the equipment regularly;

(5)Take initiative to eliminate the troubles rapidly at site;

(6) Distribute the guarantee fittings door-to-door;

(7) provide perfect service;

(8) Provide technical exchanging;

(9) Provide maintenance for big items.