Dongguan Zehui machinery equipment co., ltd |

|

Verified Suppliers

|

|

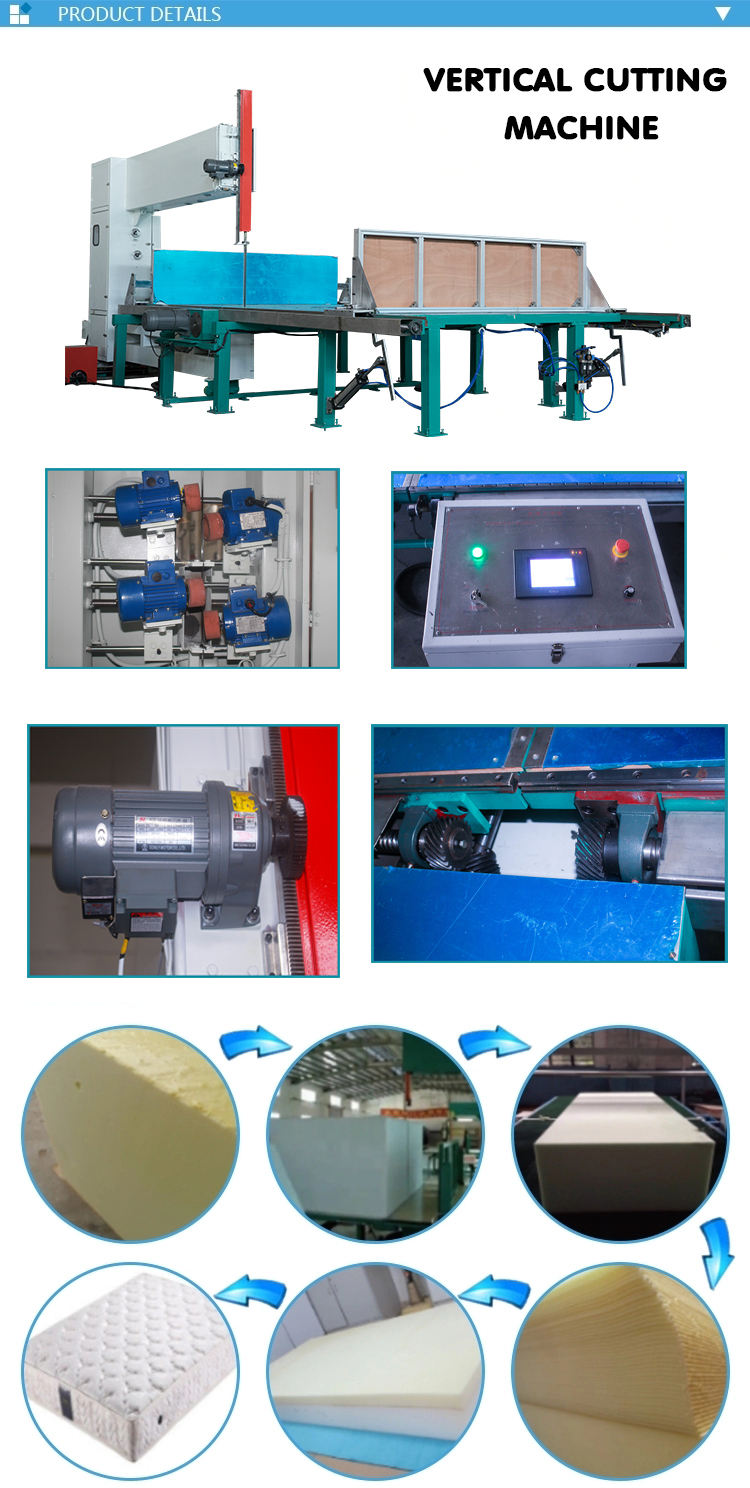

Zehui Automatic Sofa Sponge Cutting Machine & Foam Sheet Cutting Machine

This cutting machine is designed as a fixed table on which cutting device can automatically move,the foam block is fixed by boards and the thickness can be automatically controlled,the knife belt moves backward and forwards to cut the foam.The machine adopts automatic control and cuts precisely.It is the best choice for the need to cut the same thickness of continuous foam.

| Inside table size | W1720×H2440mm

|

| Outside table size | W2000×H2440mm

|

| Cutting height | H1100mm

|

| Cutting thickness | 3mm

|

| Blade length | L9930mm

|

| Motor power | 5.5KW

|

| Voltage | 3 Phase AC 380V

|

| Machine external size | L3500*W2150*H1100mm

|

| Weight | 1500KG |

Features :

1. Easy-handle, low failure rate, fast cutting

2. Cutting and sharpening can be controlled separately.

3. Cutting size can be easily adjusted.

4. The knives are fixed to guarantee the cutting size more

accurate.

5. The whole machine has protection functions such as short circuit

and overload.

1. We will offer the operation manul with the video for the install, operate and maintain of this machine.

2. Value clients, guarantee equipment quality and answer clients’ questions anytime and anywhere.

3. Customizing machines according to clients' inquiry , such as different design, different brand parts, different colors, more function,etc.

4. Engineers go to clients' factory in time for installation , training and trial production . ps:We will send 2-4 experience engineers to install and testing the machines.

Q: How to use this machine?

A: This is the manual operation you can just move the worktable by hand adjusted the size you need easy operation.

Q: What is the advantage of your machine?

A: Baffle adopt dia30mm beeline rail Worktable adopt T25mm Beeline rail and three T75 lift rail

Q: For the cost of the engineer how much I need to pay?

A: You need to pay USD50 one day for one engineer and also need to pay for the visa fee turn-round ticket fee and food hotel.

Q: Can your factory customize the machine for clients ?

A: Yes, we can.