Xi'an Kacise Optronics Co.,Ltd. |

|

Verified Suppliers

|

|

KWS-1600 NO2 - Nitrate Sensor

1. Introduction

The reference electrode silver/silver chloride electrode is encapsulated in a closed electrolyte cavity, and the working electrode gold electrode is directly placed. Test solution contact, reference electrode through the ionic membrane and the external solution to complete the charge exchange NO2- in solution. Directly on the surface of the working electrode is oxidized to form a current, the current size and solution of NO2- proportional to content.

2. Features

l no pharmacy

lNo film, not affected by surfactants.

lNo micropores, there is no danger of holes blocking in the sewage.

lRS485 digital output.

lEasy maintenance, no need to replace the diaphragm.

lAutomatic temperature compensation

lNo pressure balance required

3. Technical Specifications

Model | KWS-1600 |

Range | 0~2 ppm |

Material | Polyacetal resin, PTFE, Gold, Silver Polyformaldehyde resin, teflon, gold, silver. |

Accuracy | ±0.1% |

Operating Temperature | 5~50℃ |

PH | 5-9 |

Power Supply | 12VDC |

Output | RS485, Modbus |

Electrolyte life | One year |

Power Supply | 12V |

Flow rate | 10-40l/min |

Installation | Flow cell installation

|

Calibration | one-point slope calibration, zero calibration |

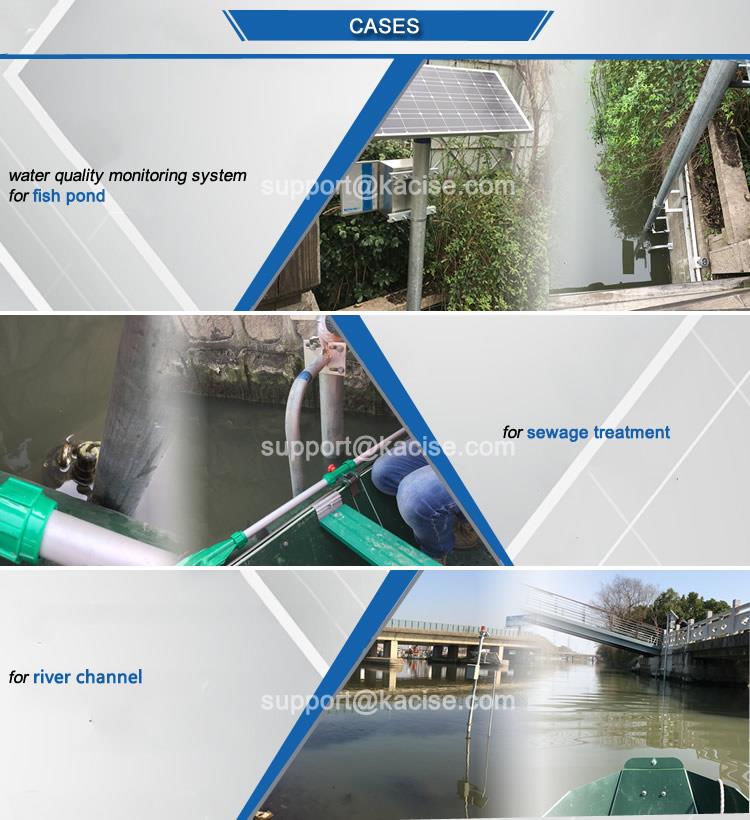

4. Application range

l lTap water

l l sewage

l l Fish pond

l l Natural water body

5. Installation

Flow cell installation

6. Maintenance

This electrode has different zero points for different water bodies, so it is necessary to mark the zero point.

Calibrate the electrode with a standard solution:

At different concentrations of NO2- , from the lean to the rich, test the potential of the electrode. Record the value of mA and NO2- , draw electrode"mA--NO2- "

Standard curve. Do not need to draw a standard curve if using ion meters. Operate accordingly to the user manual.

NO2- Standard solution, please see: GB5750.5.10-2006;

7. Structure

8. NO2-sensor use precautions (no film series)

8. NO2-sensor use precautions (no film series)

When using the electrode, it should ensure 10-20L/H running water in the flow cell to ensure the accuracy of the measurement data. If there is no water in the flow cell, the electrolyte will evaporate and the electrode will be invalid.

When the electrode is not used for the long time, the protective cap should be worn and immersed in water to prevent evaporation of the electrolyte and invalidate the electrode.

9. NO2-sensor maintenance (no film series)

1. Prepare the electrolyte.

Fill the electrolyte bottle with distilled water and shake it repeatedly until it is completely dissolved. Seal the bottle for further use.

2. Inject the electrolyte. l

Place the white silicone rubber cap with on the front of the sensor. l

Screw down the front end of the sensor (sensor cap) with the silicone rubber cap l

Be careful not to get the black mat on the sensor down (this mat is a selective ion diaphragm, not a normal rubber mat) l

After cleaning the sensor cap several times with distilled water, invert it to dry l

Open the electrolyte bottle cap l

Put the electrolyte into the sensor cap until a small amount of electrolyte overflows, taking care to avoid mixing bubbles as much as possible.

3. Install the sensor l

Screw the sensor cover together with the white silicone rubber cap onto the sensor body

Tighten the sensor cap by hand l

Remove the white silicone rubber cap and keep it for future use l

Wipe excess electrolyte with soft paper

4. Sensor Repire

If the sensor is out of water for more than 48 hours, perform the following steps to fix it.

After replacing the electrolyte according to the above steps 1, 2, immerse the sensor in clean water (normal tap water) for 3-5 days (Note: the sensor is connected to the controller and is powered on), then repeat steps 1, 2 and replace the electrolysis again. The sensor can be used normally after recalibration after 24 hours.

5. Daily inspection of the sensor l

Regularly check whether the sensor is contaminated by dirt, algae or air bubbles. Bubbles can be removed by increasing the flow rate. l

Frequently use the method to detect the measured value of the controller. If the deviation is greater than 5%, recalibrate the sensor. l

If the calibration cannot be completed, replace the electrolyte or selective ion diaphragm.

Xi'an Kacise is certified by ISO 9001-2008, GJB 9001B-2009, CE, intrinsic safety explosion-proof and isolated safety explosion-proof, etc. which assure our products are conform to the international standards.

We have been specializing in manufacturing pressure, level and flow measuring instruments and related products for 10 years. We have experienced technical and management personnel, through the efforts of our entire staff, we have become a professional measuring instrument manufacturer and solution provider. And we are continuously trying to improve product quality.

Currently, Kacise sensor is already exported to America, Spain, Australia, Chile and 20 other countries and regions, and received many favorable feedbacks. Our overseas distributers are also increasing. We regards “reasonable prices, efficient production time and good after-sales service” as our tenet, and hope to cooperate with more customers for mutual development.