Changshu Changhua Zhizao Technology Co., Ltd. |

|

Fully Automatic Cotton Hand Gloves Knitting Machine Price For Knitting Gloves

PRODUCT DESCRIPTION:

The industrial hand glove making machine adopts a high-quality sinker weaving system with high-quality materials and superb processing and assembly techniques. The electronic control system is stable, simple and easy to operate.

Equipped with self-stop protection devices such as yarn breakage, poor doffing, counting, motor overload, etc., to increase output. Suitable for all kinds of raw materials, it can knit full-finger, half-finger, cold-proof and warm gloves, and can also knit light-weight labor protection gloves for construction sites and factories. Optional hot-melt yarn device, code change device, two-color three-color device, half-finger, finger-finger, finger-two-color device, etc.

PRODUCT FEATURES:

| Contacts | 7G | 10G | 13G |

| size | L3:58/L2:52/L:46/M:42/S:37 | L3:73/L2:68/L:63/M:58/S:53 | L3:98/L2:93/L:88/M:83/S:78/XS:73 |

| Average yield | 18 pairs/hour | 14 pairs/hour | 7 pairs/hour |

| Container capacity | 48 units/20’FT; 96 units/40’HQ | ||

| power supply | Single-phase power supply,220V,140W | ||

| Fuel supply method | Automatic oil supply | ||

| Weave density | Stepper motor control | ||

| control and display system | Computer control, 7-inch touch screen display, USB data transmission | ||

| Transmission system | Belt drive, AC servo motor | ||

| Nose | Ultra-small and ultra-thin head design | ||

| size | 1000mm(L)*600mm(W)*1100mm(H) Dimensions without yarn holder | ||

PRODUCT DETAILS

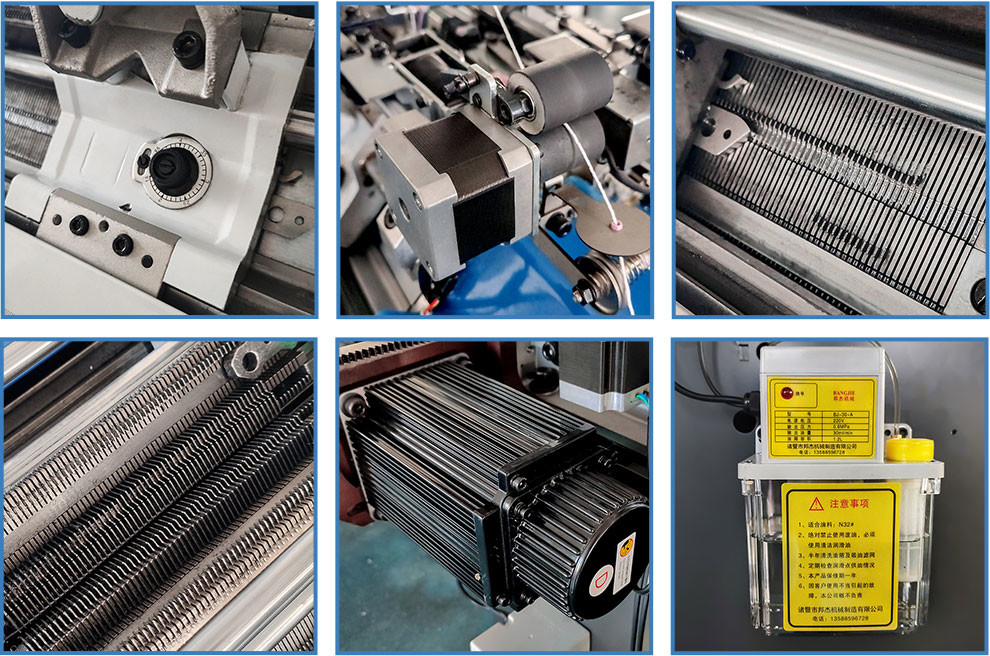

Needle bed

Formed by inserting special high-precision plates.These needle

plates are made of special steel using state-of-the-art hardening

technology, providing high strength and durability for high-speed,

high-quality product manufacturing.

Ultra small nose

The ultra-thin and ultra-small machine head greatly reduces its

operating load and energy consumption. The lightweight machine head

can reduce the inertial impact force generated by its reciprocating

motion, achieve rapid rotation, and improve the efficiency of the

preparation.

Rubber density motor

The stepping motor is used to uniformly transport the length of the

rubber thread, which can quickly and conveniently adjust the width

of the mouth of the glove.

servo motor

The servo motor is used as the main control motor to accurately

control the reciprocating movement of the machine head, which

greatly reduces the complicated transmission components of the

previous glove machine and eliminates mechanical failures.

Automatic oil supply

The intelligent oil supply system automatically adds lubricating oil to the required parts to reduce wear.

APPLICATION FIELDS

Maintenance of Glove Making Machines:

NOTE: Always turn off the power when performing full maintenance on

the machine.

1. Please dust off the flannel on the needle plate and other parts every 8-12 hours, and blow it off with an air gun.

2. Check the air filter once a week to remove the scale inside.

3. Clean the oil pump once a year and clean it with detergent.

4. The needle plate and sink seat are most likely to accumulate dust, and if they cannot be cleaned in time, it will have adverse effects.

FAQ

Q1: Supplier Profile

A2: We are a manufacturer of glove machines, and our machines are

exported to more than 40 countries including India, Bangladesh,

Mexico, and the United States.

Q2: Product introduction

A2: This machine is suitable for the production of labor insurance

gloves.

Q3: Machine warranty

A3: One year. For any accessories of the machine, customers can buy

from us.

Q4: Delivery time

A4: Usually 15~30 days after payment, depending on the number of

machines and the order of the factory at that time. If the machine

you need is in stock, we can ship it quickly.

Q5: How do you ship the goods and how long does it take to arrive?

A5: Ship by DHL, UPS, FedEx or TNT. It takes 3-5 days to arrive.

Airline and sea shipping also optional.

Q6: Machine package

A6: The inner layer is plastic packaging to avoid dust; the outer

layer is wooden packaging and iron chassis to protect the machine

during transportation.

Q:7Can the machine be customized?

A7:Yes, we can customize according to your needs, please confirm

the details with us in advance before purchasing.

Q8: After-sales service

A8: Firstly, Our products are produced in strict quality control

system and the defective rate will be less than 0.2%.

Secondly, During the warranty period, if there is any problem with

the accessories, we will send it to the customer for free (the

courier fee needs to be borne by the customer); after-sales

services can be provided (the customer needs to bear the travel

expenses of the after-sales personnel).If the product is outside

the warranty period, we can provide video assistance services, and

if there is a problem with the accessories, we sell it to the

customer at the cost price