Shanghai Rising International Trade Co., Ltd. |

|

Cold Worked 3004 Aluminum Alloy For Thinner Beverage Cans Application

Difference between Alloy 3004 and 3003:

3004 aluminium alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy with moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded, but typically not forged. As a wrought alloy, it is not used in casting.

The alloy 3004 is commonly used in the making of beverage cans. It was developed to satisfy the need for thinner gauges in can-stock, and thereby to some extent replaced its predecessor 3003 alloy in the making of beverage cans. Can-stock can be made thinner due to the addition of 1% magnesium, which contributes in solid solution strengthening.

Alloy Designations:

Alternate designations include 3.0526 and A93004. 3004 aluminium and its various tempers are discussed in the following standards:

Chemical components:

The alloy composition of 3004 aluminium is:

1. Aluminium: 95.6 to 98.2%

2. Copper: 0.25% max

3. Iron: 0.7% max

4. Magnesium: 0.8 to 1.3%

5. Manganese: 1.0 to 1.5%

6. Silicon: 0.3% max

7. Zinc: 0.25% max

8. Residuals: 0.15% max

Physical Data of 3004 Aluminium Alloy:

| Density (lb / cu. in.) | 0.098 |

| Specific Gravity | 2.72 |

| Melting Point (Deg F) | 1170 |

| Modulus of Elasticity Tension | 10 |

| Modulus of Elasticity Torsion | 3.8 |

Advantages of Our 3004 Aluminum Sheet:

*. High precision competitive strength products

*. No-standard/ OEM/ODM/ customized service provided

*. Can meet SGS, BV standard

*. Small order available

*. Fast lead time

*. Timely after-sales services

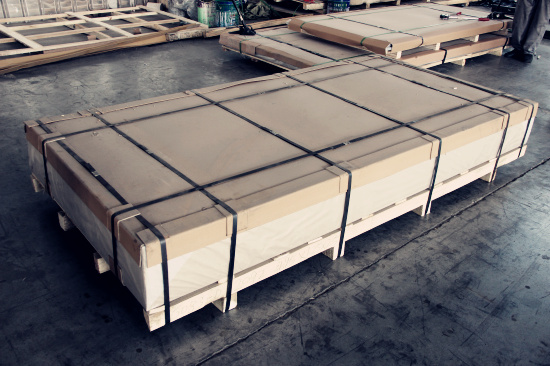

Factory and Packaging:

Applications of 3004 Aluminium Alloy: