Sichuan Zhuoan New Materials Technology Co., Ltd. |

|

steel structure fireproof coating

ZOAN 601 is a decorative, fiber free, thin film intumescent coating designed for the fire protection of steelwork for up to a 3 hour fire rating, depending on the design. The recommended use for this product is fireproofing of interior steel beams, columns, tubes, and pipes.

Specification :

| Product Color | White liquid |

| Film Paint Color | White |

| Fireproof rating | 30-180min, depend on the film thickness |

| Construction Usage | 3.1 kg/sqm |

| Surface Drying Time | 3 hrs |

| Hard Drying Time | 8 hrs |

| Film thickness | Less than 3mm(as per china standard) |

| Color Customization | Support |

| Water Proof rating | More than 24 hours |

| PH | 7-8 |

| Consturction Ambient Temperature | Between 5ºC (41ºF) and 30ºC (95ºF) |

| VOC | / |

| Shelf Time | 6 months |

| Application Method | Brush/spray/roller |

Range of application

Used in Indoor and outdoor steel structure,such as factories , warehouses ,real estate and other building

Main Features

1.Excellent fireproofing performance

2.Decorative Finish – Gives a smooth, decorative finish. Compatible topcoats available in a wide range of colors.

3.Advanced fiber free formulation - dust free surface.

4.Durable finish – Provides a hard, impact and abrasion resistant surface.

5.Thin film coating – space saving smaller column footprints.

6.Low VOC content.

Construction process

The first times of mixing ratio of water: agent: LG should be (60~75):40:40.Then the following times of mixing ratio should be (60~75):40:80, then the water, adhesion agent and powder proportion shall be (90~110):40:80;(80~120):40:80.

Then agent should be added to water first and stir them thoroughly, then add LG into the mixer. The coating should be used over within 90 minutes after mixing . Additional water might be added depending on air condition and application tools.

We can adjust the water ratio in accordance with the real situation.

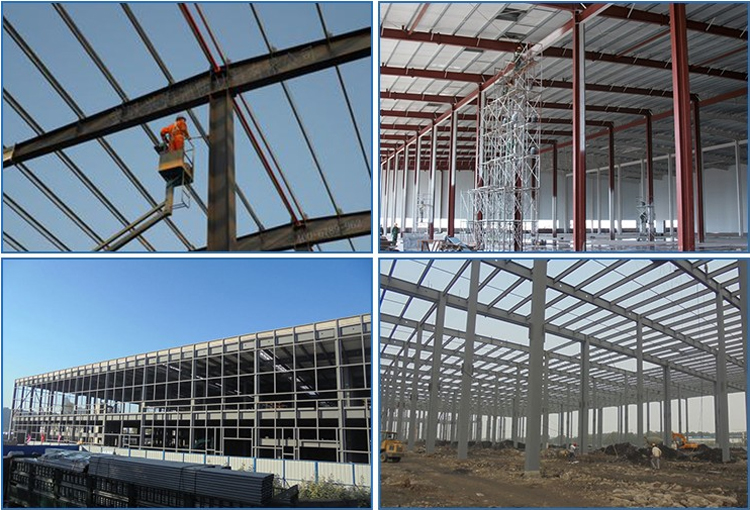

Construction site

We’ve got ISO9001, all Chinese national tests and certification, SGS , REACH, ROHS.

June 1996 obtained ISO9001 certificaiton by the TUV Germany. (

Certificate ) Sep. 1996 obtained ISO9001 cerification by the Bureau

of Standards, Metrology and Inspection, MOEA. ( Certificate )

UL Certifications

Fire Protection Coatings(interior)-UL File No. R14635-Design No.

D778,D768,Y701,Y703,Y706,Y711, Inverstigated for Exterior

Use.-GREENGUARD UL2818 Standard Gold StandardCertification 1

Certification 2 Fire Protection Coatings(interior)-No.

R14635-Design No. XR713,N770,Y706,Y716,Y717, Inverstigated for

Exterior Use.-GREENGUARD Certification 1 Certification 2 Epoxy

Intumscent Fire-Retardant Coating- File No. R14644 Water-based

Intumscent Fire-Retardant Coating-File No. R13583 Solvent-based

Intumscent Coating -File No. R13583

BS Certifications

No. C105787,C110854,C114287,C114288,C114381,C114 tabeo

Solvent-based Intumscent Fire Resistance Mastic Coating No.

TE92771,TE94121,TE94123

MOI Application

F-1, F-100, FM-900

Green Mark

NO.450 Flat lavender NO.450 Flat orange NO.450 Flat oriental cherry

red NO.450 Flat barley white NO.450 Flat beige NO.450 Flat rose

white NO.450 Flat lily white NO.450 Flat white NO.450 Gloss

lavender NO.450 Gloss green NO.450 Gloss sky water blue NO.450

Gloss white NO.450 Gloss lily white NO.450 Gloss rose white NO.450

Gloss beige Gloss Emulsion Paint

GBM MARKER

FM-906 Firecut Water-base expansion Fire-resistant Putty Coating

NO.406 FM Water-based Cement Paint (outdoor) NO.421 Water-based

elastomeric finish coat NO.424 Water-based Cement Paint (outdoor)

NO.428 New Home Paint - Flat Enamel NO.428 New Home - Glossy NO.432

Easy Clean Emulsion Paint NO.433 Golden Acrylic Emulsion Paint

NO.436 Emulsion Paint, Mat NO.436 Emulsion Paint, Mat-2 NO.450

Gloss Emulsion Paint NO.450 Gloss Emulsion Paint-2 NO.450 Flat

Emulsion Paint NO.450-1 Water-based Cement Paint - half flat enamel

NO.500-1 Flat Emulsion Paint-2 NO.500-1 Flat Emulsion Paint NO.650

Flat Emulsion Paint NO.650 Gloss Emulsion Paint NO.860 Flat

Emulsion Paint-2 NO.860 Flat Emulsion Paint NO.1015AS Epoxy finish

coat NO.1030 Water-based Epoxy finish coat-2 NO.1030 Water-based

Epoxy finish coat SA3000 Water-based Elastomeric Dust-resistant

Paint UP-200 Indoor Flooring PU YWP Water-based Woodenware Primer

YWP Water-based Woodenware finish coat Rainbow Emulsion Paint -Flat

enamel GOLDEN EMULSION PAINT, FLAT

CNS Certification

CNS A2091 Construction Waterproofing PU. CNS K2006 Ready-mixed

Paint (Synthetic Resin Type) CNS K2011 Enamel Paint CNS K2020-1 Red

Oxide Primer (1st Type) CNS K2020 Red Oxide Primer (2nd Type) CNS

K2029 Alykd Enamel Paint CNS K2031 Traffic Paint (1st Type) CNS

K2041 Acid-Resisting Paint CNS K2050 Heat-Resisting Paint CNS K2070

Chlorinated Rubber Finish CNS K2086 Epoxy Zinc-free Primer CNS

K2087 Epoxy Zinc Rich Primer CNS K2088 Inorganic Zinc Dust Primer

(solvent type) CNS K2089-1 Epoxy Paint (1st Type) CNS K2089-2 Epoxy

Paint (2nd Type) CNS K2089-3 Epoxy Paint (3rd Type) CNS K2089-4

Epoxy Paint (4th Type) CNS K2090-2 Epoxy Bituminous Paint (Type 2)

CNS K2090 Epoxy Bituminous Paint (Type 1) CNS K2091-2 Water-based

Cement Paint (Type 2) CNS K2091 Water-based Cement Paint (Type 1)

CNS K2125 Solvent-based Cement Paint

Packaging Details: 20kg/bag. Transported as general chemicals.

Delivery Detail: about 15 days after receipt of payment

FAQ