Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

Dellok G Embedded Fin Tube Serrated Fin Tube

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

Product Description

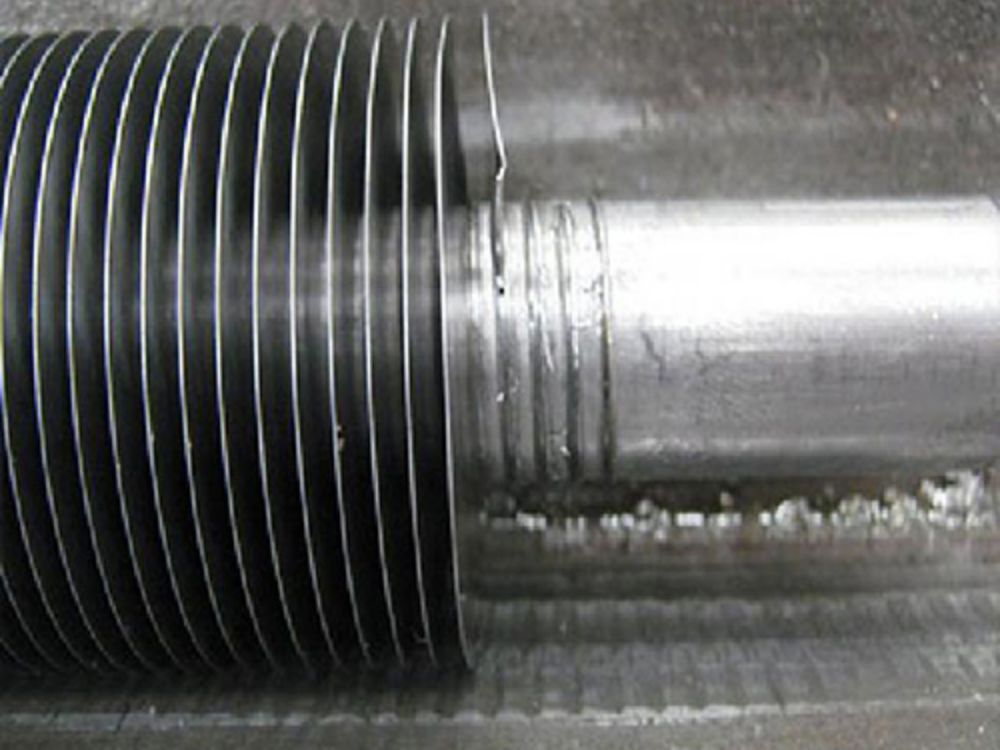

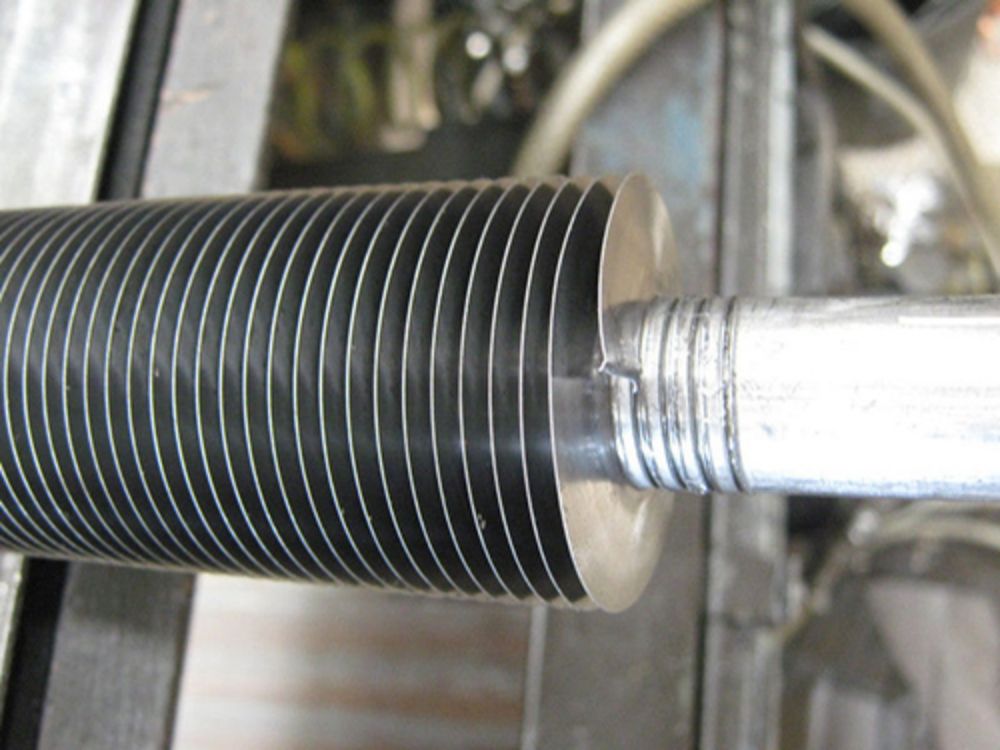

Embedded Fin Tube G Type is made with the fin strip wounded into a machined groove and securely locked into place by back filling with base tube material. This technique ensures maximum heat transfer and a temperature of working until 450C°.The fin strip is wound into a machined groove and securely locked into place by back filling with base tube material. This ensures that maximum heat transfer is maintained at high tube metal temperatures.

G Finned Tube Manufacturing Process

A helical groove is formed in base tube displacing of material and fin is wound into the groove under tension, followed by backfilling of the displaced material to lock the fin root into the tube.

Fin materials: Aluminium Base

Tube materials:Any readily machinable materials

G Finned Tube Advantages

High fin stability, excellent heat transfer, high operating temperature.

G Finned Tube Properties

Common Applications:Air Cooled Heat Exchangers, Steam Coils, Air Preheaters.

Max. Working Temperature: 400℃

Atmospheric Corrosion Resistance: OK

Mechanical Resistance: Poor

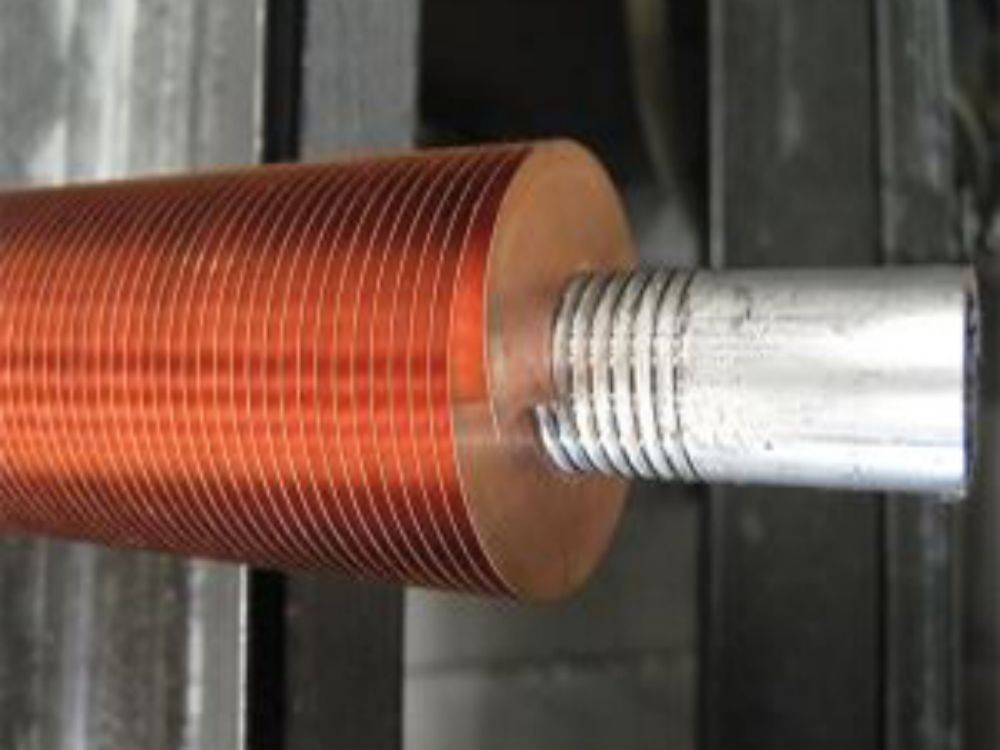

Fin Material: Copper,Aluminum

Base Tube materials: Any material available, such as Carbon steel Tube, A179,A192,A210, stainless tube A269/A213 T5 T11 T22 304 316

G Finned Tube(Copper Finned Pipe) Applications

These Fin Tubes find application in air fin coolers , radiators etc. and are preferred in Industries like Power Plants,Chemical Industries,Petroleum Refineries,Chemical Plants ,Rubber Plants , etc

G Finned Tube Specifications

| Product Specification | ||

| Tube OD | 19~51 (mm) | 3/8”~2” |

| Tube Wall Thk | 2.11~3.5(mm) | 0.083”~0.138” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.012”~0.02” |

| Fin Height | 10~16 (mm) | 0.394”~0.63” |

| Fin Pitch | 100~433 FPM | 3~11 FPI |

| Fin Type | G | |

| Material Combinations | ||

| Fin Material | Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) | |

| Copper | ||

| Tube Material | C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) | |

| S.S. (most common grade: TP304, 316) | ||

| Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi 90/10) | ||

| Titanium (most common grade: B338Gr2) | ||

| Applied | 400°C | |

| Temperature | ||

| Type of Service | High temperature | |

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.

Q5: What payment terms do you accept?

A :Trade assurance,TT,Western Union.