Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

DELLOK High Pressure Boiler Carbon Steel Studded Tube

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

Studded Tube Product Description:

Studded tubes are a type of metal tubes. These tubes have studs welded onto the metal tube.These studs are arranged in a specific formation throughout the length of the tube.They are often used in boilers and refineries. As they increase the surface area for higher heat transfer they are used for reheating.

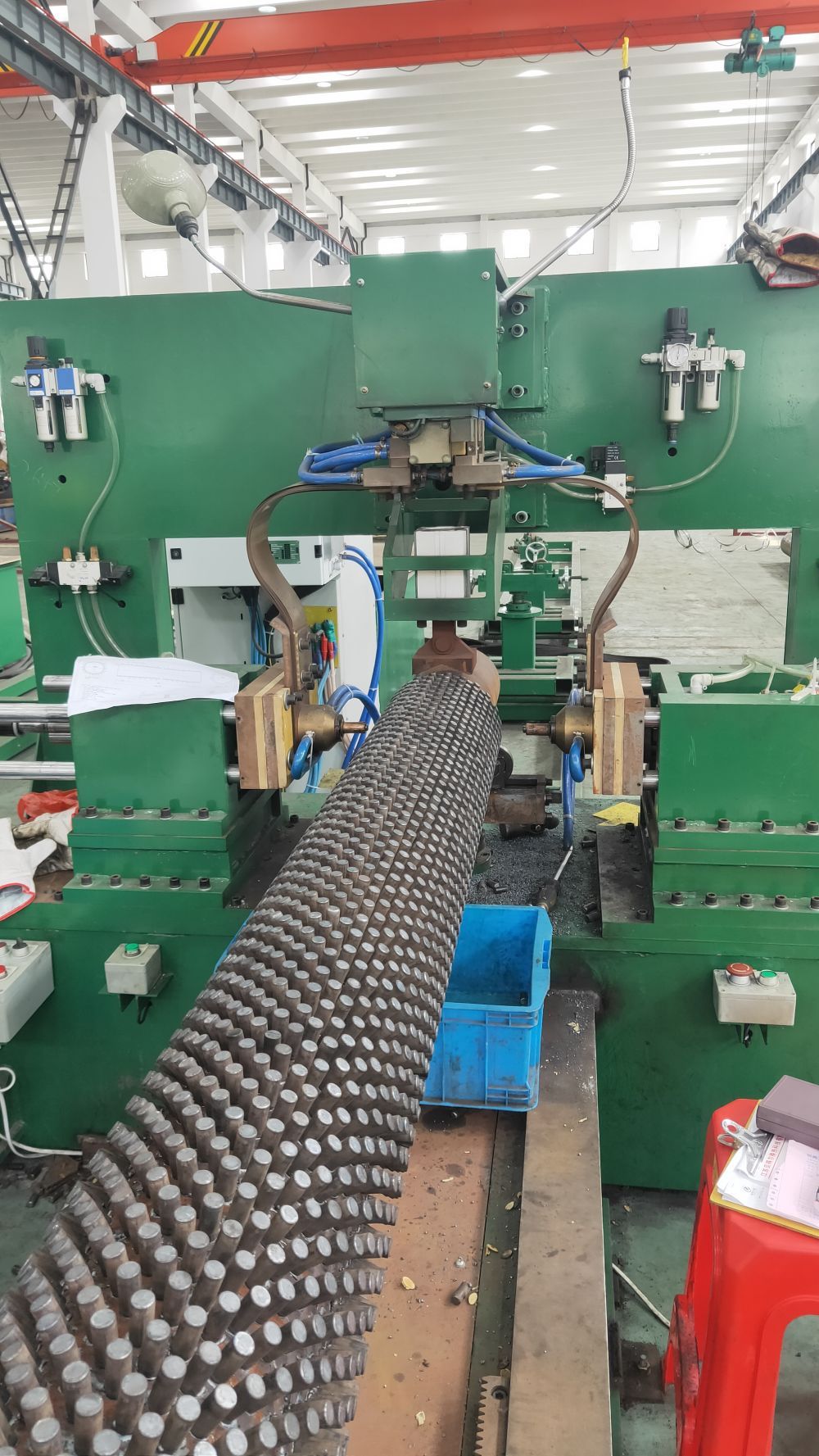

Studded Tube(Stainless Steel Welded Tube) Manufacturing Process:

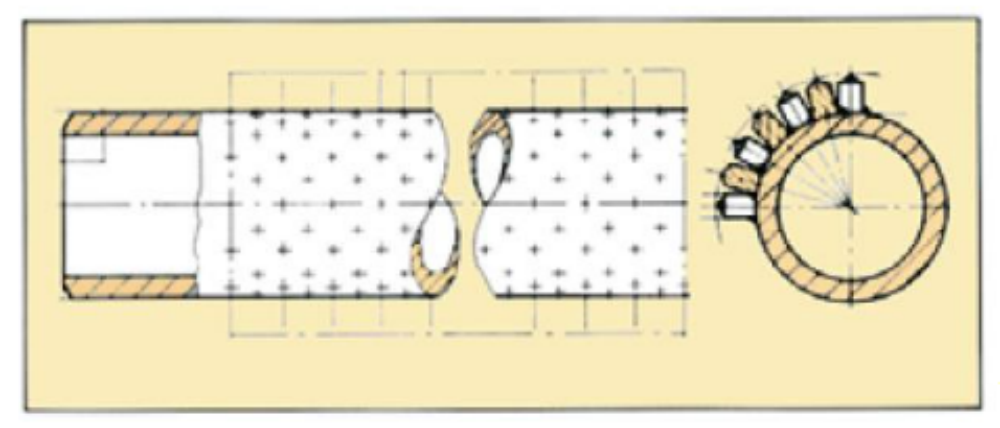

Steel studs are welded onto the base tube. Studded Tubes Type of Studs Cylindrical , elliptical or lens type.

Studded Tube(Welded Stainless Tube) Advantages:

1)Satisfying connection surface, little heat loss .

2)Welding connection rate higher than 90 percent.

3)No need of welding power, hardly any welding tumor .

4)Narrow heated zone on the surface, no melted pool, without destroying the tissue of basic tube.

5) Welding parameters are strictly set to ensure the quality of bulk Studded Tube and avoid the instability of manual operation.

Studded Tube(Black Welded Pipe) Properties:

It occupies less space and is compact.

Highly durable.

Studded Tube(Weld Galvanized Pipe) Applications:

Studded tubes and studded pipes are widely used in heat recovery applications of petrochemical plants,oil&gas and chemical processing, mostly in areas of convection ovens, at very high temperature and harsh environments where corrosive elements such as sulfuric acid could be present.

Studded Tube(Fin Tube) Specifications:

| Product Specification | ||

| Tube OD | 25~273 (mm) | 1”~10” (NPS) |

| Tube Wall Thk | 3.5~28.6 (mm) | 0.14”~1.1” |

| Tube Length | ≤25,000 (mm) | ≤82 ft |

| Stud Thk | 6~25.4 (mm) | 0.23”~1” |

| Stud Height | 10~35 (mm) | 0.4”~1.38” |

| Stud Pitch | 8~30 (mm) | 0.3”~1.2” |

| Stud Type | Cylindrical, Elliptical, Lens type | |

| Stud to tube surface angle | Vertical or Angular | |

| Material Combinations | ||

| Stud Material | C.S. (most common grade: Q235B) | |

| S.S. (most common grade are AISI 304, 316, 409, 410, 321,347) | ||

| A.S. | ||

| Tube Material | C.S. (most common grade: A106 Gr.B) | |

| S.S. (most common grade are TP304,316, 321, 347) | ||

| A.S. (most common grade are T/P5,9,11,22,91) | ||

| Type of Service | High temperature | |

Product Categories : Studded Tube

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products

.

Q5: What payment terms do you accept?

A :Trade assurance,TT,Western Union.