Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

DELLOK High Frequency Welded Stainless Steel Longitudinal Fin Tube

About Us

Dellok(YONGHUI Radiating Pipe Manufacturing Co.,Ltd) was established in 2002, which is located in Nanjing, China.We joined HARBIN AIR CONDITIONING CO., LTD. in 2022 and became the most professional industry manufacturer in China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above.

Quality is the theme of eternal pursuit of winner.

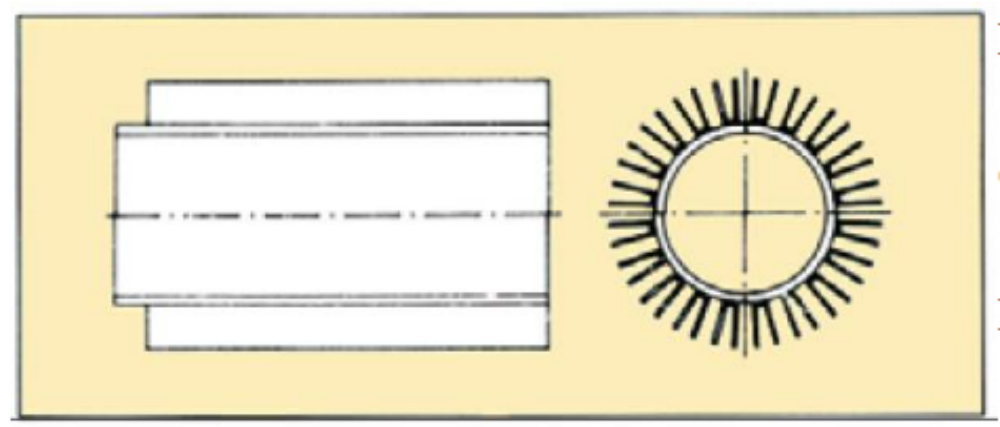

Longitudinal Finned Tube Product Description:

Finned tubes (or finned pipe) are produced by resistance welding fins in diametrically opposite pairs. The way channels are welded on the external surface of the tube makes them highly efficient.

They are formed from a U channel of material, with the base being pressure rolled and spot welded to the tube or pipe. The number of fins must always be a multiple of four.

All our finned tubes can be manufactured from most weldable or brazable materials. The finned pipe is supplied in straight lengths or U bent form.

Longitudinal Fin Tube Manufacturing Process:

The longitudinal fin tubes are welded onto the core plain tubes by resistance welding or welding with filler metal.

Longitudinal Fin Tube(Carbon Steel Welded Pipe) Advantages:

Provide 8 to 12 times the heat transfer area of bare tubes.

Are more efficient than bare tubes.

Provide smaller exchangers due to increased Heat Transfer area.

Often provide a more economical selection.

Fins can be "Cut & Twist" to increase shell side fluid turbulence and improve heat transfer.

Brown Fin Tube Properties:

Improve heat transfer efficiency in efficient space.

Reduces installation space on required heat transfer surfaces.

Reduce the cost of the equipment, and have a high operational reliability.

The pressure drop on the side of the tube is reduced and the operation cost is reduced.

The stiffness of steel tube is improved, and the seismic performance of steel tube is improved.

Enhance heat transfer, reduce flow resistance and metal consumption.

Longitudinal Finned Tube(Welded Steel Pipe) Applications:

We supply longitudinal finned tubes for:

double pipe heat exchangers

multi-tube heat exchangers

fire rated heaters

gas coolers

tank heaters

And we are able to accommodate the requirements of various industries, including oil, power, chemical, and petrochemical.

Longitudinal Finned Tube Specifications:

| Product Specification | ||

| Tube OD | 16~273 (mm) | 3/8”~10”(NPS) |

| Tube Wall Thk | 2.11~25.4 (mm) | 0.08”~1” |

| Tube Length | ≤12,000 (mm) | ≤39 ft |

| Fin Thk | 1.0~1.5 (mm) | 0.04”~0.06” |

| Fin Height | 5~25 (mm) | 0.2”~0.98” |

| Fin Pitch | 1U~36U | |

| Fin Type | “U”or“I/L” | |

| Material Combinations | ||

| Fin Material | C.S. (most common grade: Q235B) | |

| S.S. (most common grade are AISI 304, 316, 409, 410, 321,347) | ||

| A.S. | ||

| Tube Material | C.S. (most common grade: A106 Gr.B) | |

| S.S. (most common grade are TP304,316, 321, 347) | ||

| A.S. (most common grade are T/P5,9,11,22,91) | ||

Product Categories : Longitudinal Finned Tube

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.

Q5: What payment terms do you accept?

A :Trade assurance,TT,Western Union.