Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

DELLOK Customized Stainless Steel Welded Fin Tube Heat Recovery

About Us

Dellok(YONGHUI Radiating Pipe Manufacturing Co.,Ltd) was established in 2002, which is located in Nanjing, China.We joined HARBIN AIR CONDITIONING CO., LTD. in 2022 and became the most professional industry manufacturer in China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above.

Quality is the theme of eternal pursuit of winner.

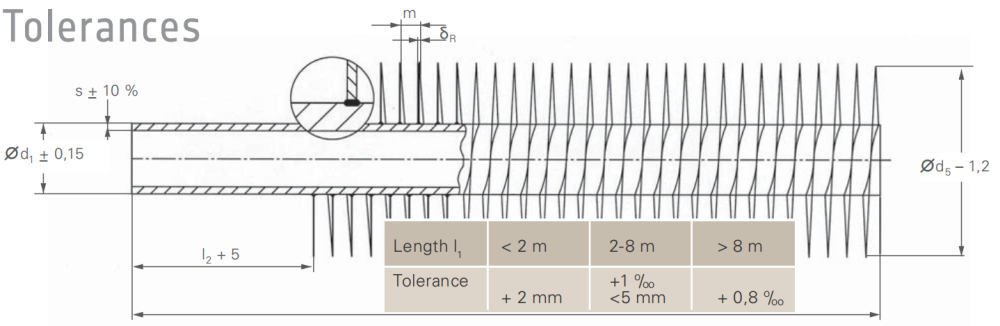

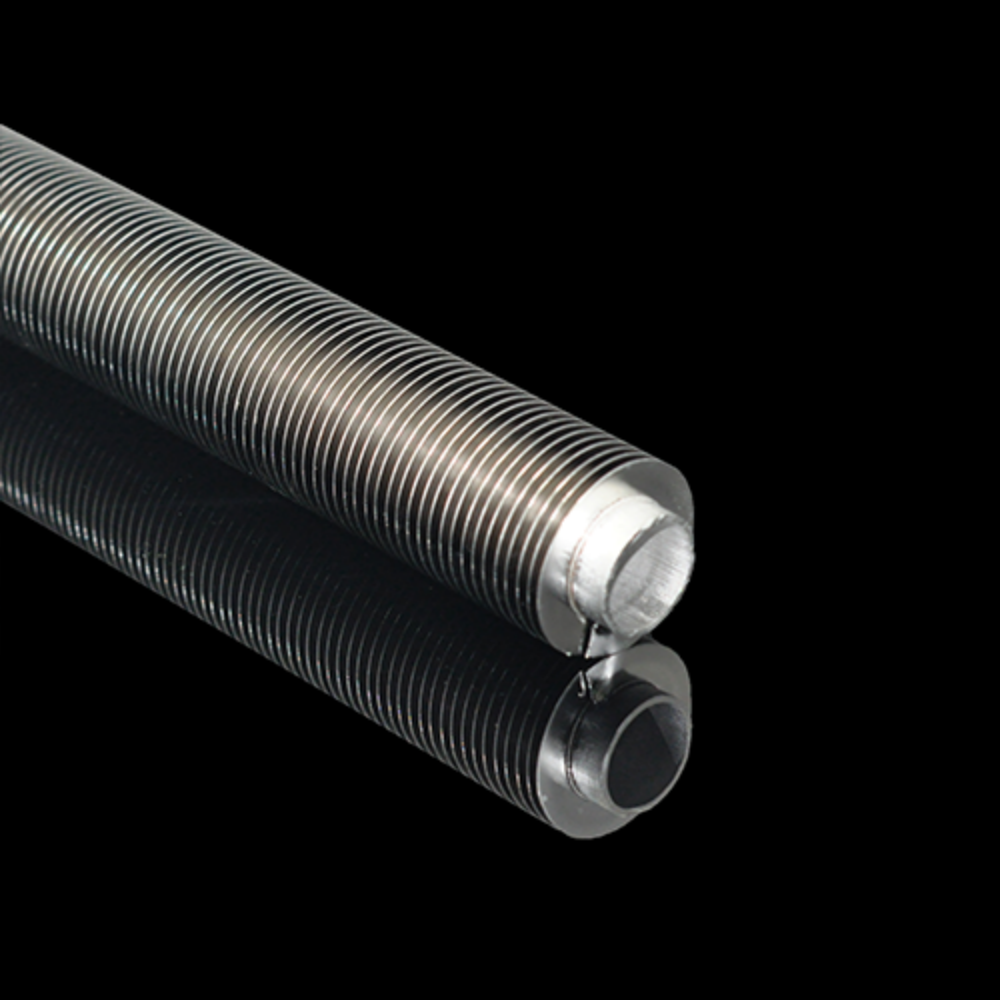

Laser Welded Finned Tube Product Description:

We produce laser welded finned tubes . And it is widely used for civil wall-hung boilers, industrial boilers, etc. By comparison, the laser-welded finned tube is the most advanced product of irreplaceable advantages. It has a high penetration rate, can prevent crevice corrosion, prolong service life and reduce heat transfer resistance. Breaking through material restrictions. And it can use different materials for processing, saving material costs, and easy for secondary processing.

The disadvantage of laser welding is that the processing time is longer and the output will be limited.

Laser Welding Fin Tube Manufacturing Process:

The fin strip is welded continuously and spirally wound onto a polished bare tube. And the tube and fins are bonded together by using advanced laser welding technique.

Laser Welding Fin Tube(Welded Spiral Pipe) Advantages:

The advantages over conventional MAG/HF welding are of decisive importance.

The complete connection between the fins and the base tube brings about excellent heat transfer and up to 2.5 times higher thermal performance of the finned tubes.

The continuous weld prevents notch effects and v Corrosion and the formation of cracks are hence avoided also in the case of possibly oscillating finned tubes.

The low base metal heating during welding and the high speed of travel of up to 20m/min. Minimize the heat-affected zone in the base tube. Complete melting of the tube and a related metallurgical transformation of the parent metals are hence excluded.

Laser Welded Finned Tube(Stainless Steel Welded Pipes) Properties:

100% welding between fin and base tube without using any filler material.

The laser welding process is carried out under the protective atmosphere, and no impurity of the weld seam.

Laser Welded Finned Tube(Stainless Steel Welded Pipe) Applications:

The fin tubes are mainly used in heating (gas-fired boilers, condensing boilers, flue gas condensers), in mechanical and automotive engineering (oil coolers, mine coolers, air coolers for diesel engines), in chemical engineering (gas coolers and heater, process cooler), in power plants (air cooler, cooling tower), and in nuclear engineering (uranium enrichment plants).

Product Categories : Laser Welded Finned Tube

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.

Q5: What payment terms do you accept?

A :Trade assurance,TT,Western Union.