Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

DELLOK Inner Grooved Integral Finned Tube For Water Cooler

About us

Professional heat exchanger factory with 20 years of experience, providing you with one-stop heat transfer solutions to design different heat exchangers according to your purposes (metallurgy, food, petrochemical, pharmaceutical, beverage, wastewater, refrigeration, etc...)

Dellok Young is a professional manufacturer of various heat exchangers integrating R&D, design, production and sales. The heat exchangers produced are mainly used in petrochemical, electric power, papermaking, building heating, mining and other industries, such as air heaters, food industry plant protein powder, starch and other air heater spray drying systems.

The company now has a professional technical innovation team and

professional after-sales personnel. The company's production plant

covers an area of approximately 18,000 square meters, has multiple

professional and advanced CNC and automated production equipment,

and has obtained a number of professional certificates and patents.

The company has a professional foreign trade team and has trade

cooperation with various regions. Some global partners conducted

on-site inspections of the production plants and were very

satisfied with the inspection results and established long-term

strategic cooperative relationships with our company.

Product Description

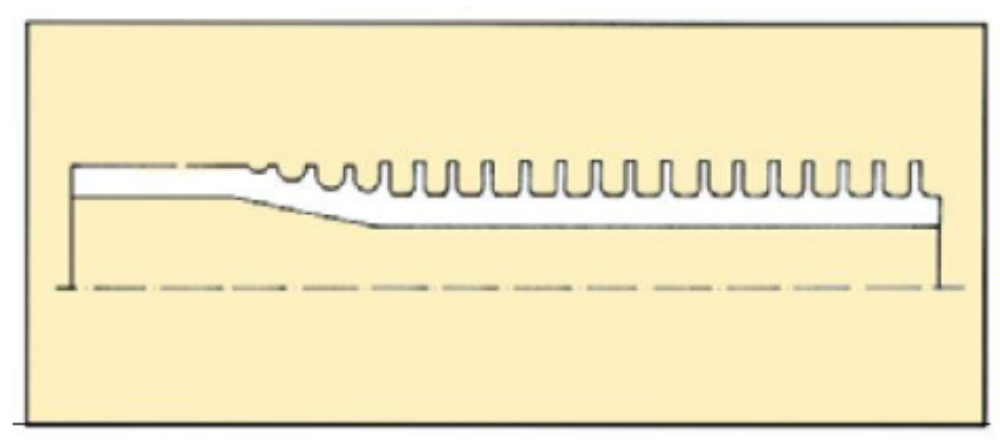

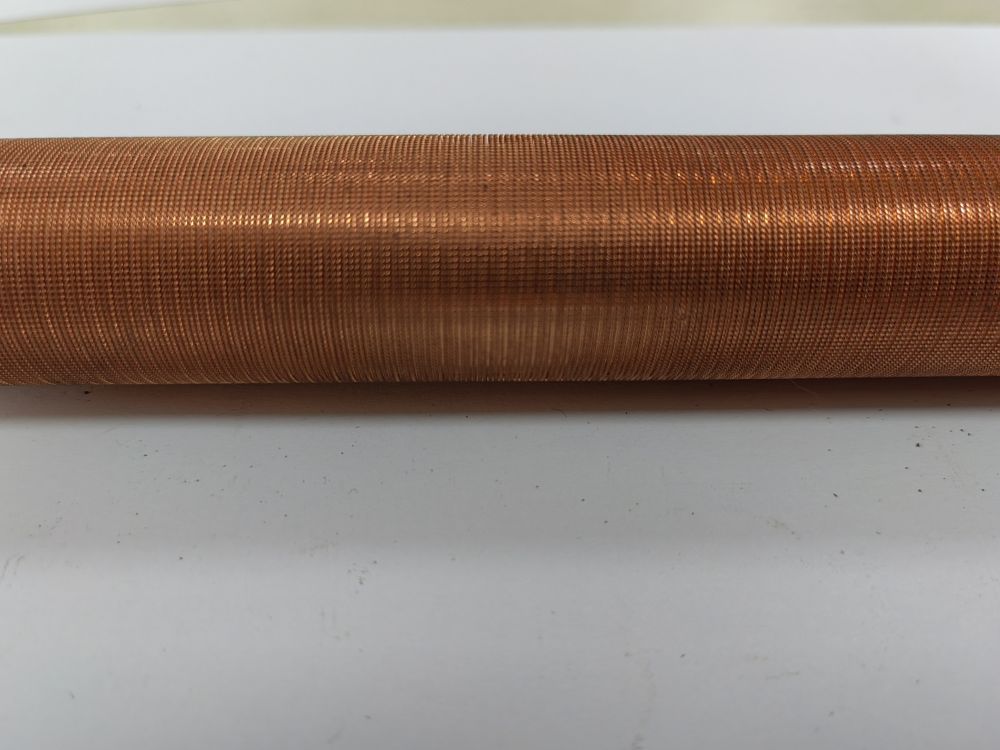

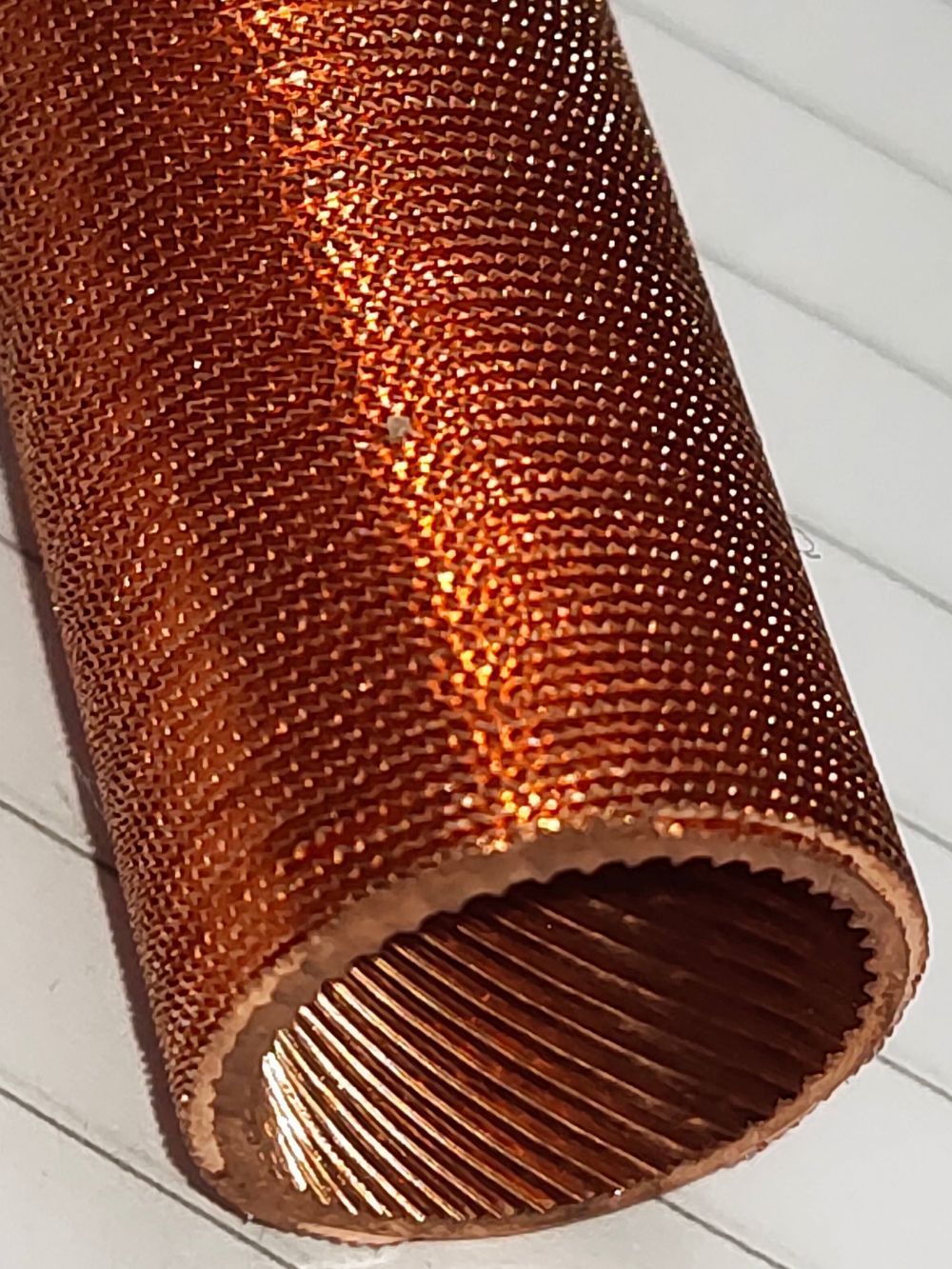

Integral Fin Tube is another name for the ‘Low Fin Tube. In today’s industry, this style of fin tube is commonly employed.Low Fin Tubes/Integral Fin Tubes are becoming more popular in fluid heat exchangers. Unlike other Fin Tubes, their use isn’t restricted to air-to-liquid heat exchangers. As a result, they’re also found in a variety of Shell and Tube heat exchangers.The fins are made by rolling the fin inside the base tube. The height of the fins is extremely low. However, by increasing the number of fins per inch or the fin density, the heat transmission area can be considerably improved. The rolling is done using a specific machine, and the finished product is available in both straight and U bend configurations.Fin Tubes are used in Oil Coolers, Shell and Tube Heat Exchangers, and other applications.

Manufacturing Process:

The fins are rolled out of the wall of the plain tube by use of a pass roller. Tube and fin consist of same piece.

Integral Low Finned Tube Advantages

Proven solution in a wide range of applications

Increased heat transfer surface compared to plain tubes

Material savings due to reduced tube length

Filling quantity reduction due to higher efficiency

Low Finned Tube Properties

Manufacturing Process:- Cold Rolling of Fin on the Base tube Itself.

Fin To Tube Bond:- NA (fin is made from the base tube itself)

Heat Transfer Efficiency:- Good

Mechanical Resistance: – Good

Corrosion Protection: – Moderate

Temperature Range:- Up to Maximum 415 Deg C

Integral Low Fin TubeApplications:

Low finned tubes are a reliable solution for controlling the temperature of gases and liquids, or for evaporating and condensing refrigerants. Thanks to their larger heat transfer surface area, they offer considerable potential to save in terms of materials and fill volumes, especially applicable to air and other gases on the fin-side and a fluid on the tube-side. Applied in Heat Exchanger for oil refinery and petrochemical plants, condenser and heat exchanger for petrochemical plants, condenser & evaporator for power plants

Integral Low Fin Tube Specifications

| Product Specification | ||

| Tube OD | 12.7~31.75 (mm) | 1/4”~1 1/4”(NPS) |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.0118"~0.0197” |

| Fin Height | 0.9~1.3 (mm) | 0.0354”~0.0512” |

| Fin Pitch | 666~1111 FPM | 16~30 FPI |

| Fin Type | Integral Low | |

| Material | ||

| Tube Material | C.S., S.S., A.S., Copper, Titanium | |

| Applied | 415°C | |

| Temperature | ||

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.

Q5: What payment terms do you accept?

A :Trade assurance,TT,Western Union.