Suzhou Rilant Machinery Co., Ltd. |

|

Steel Coil Slitting Line Cut To Length Line Machine Thick Plate

1, General Description

This 4-16×2200 Slitting line is equipped with a horizontal cutting line and slitting line. It is used to straighten and rewind the rolled steel strip. It can also cut and level the steel plates and collect them.

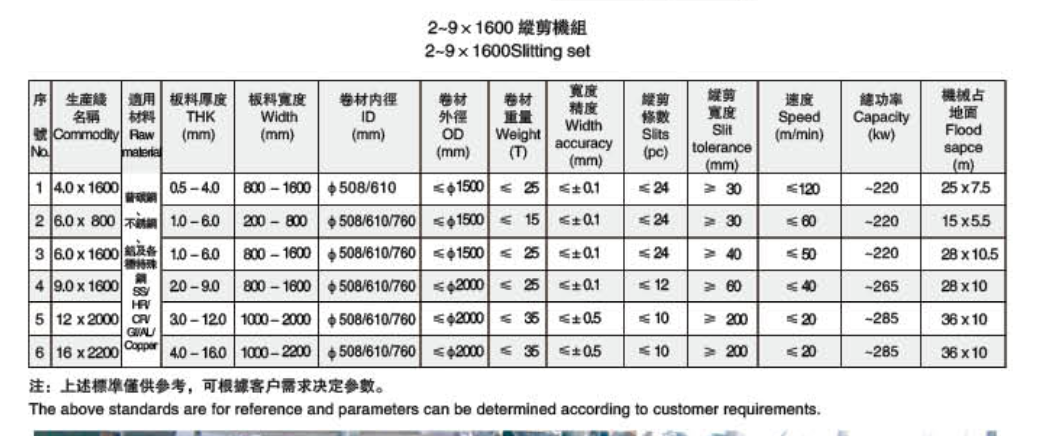

2, Machine Specifications

A, Steel coil raw material parameters

Material:Q235,stainless steel

Plate thickness:Q235:4~16mm;

stainless steel: 4~10mm

Plate width:900~2500mm

Coil I.D:ф610mm/ф760mm

Coil O.D:ф1200~ф2000mm

Coil weight:≤35T

B, Product parameters

★ Shear finished product parameters

Specified lengths:3000-8000mm

length tolerance:±1mm/3m;±1.5mm/6m

3.Diagonal tolerance:±1.5mm/3m;±3mm/3m

4.leveling accuracy:≤1.5mm/m2

5.Pallet weight:≤10000kg

★ Slitting finished product parameter

Number of slitting: Q235 plate thickness 4.0-6.0mm Max.20pcs

Min. slitting width 80mm,speed:0-60m/min

Q235 plate thickness 8.0-10mm Max.15pcs

Min. slitting width:145mm,speed 0-40m/min

Q235 plate thickness 12-16mm Max.10pcs

Min. slitting width 200mm,speed 0-20m/min

Stainless steel: plate thickness 4.0-6.0mm Max.20 pcs

Min. slitting width 80mm, speed 0-60m/min

stainless steel thickness 8.0-10mm Max. 10pcs Min. slitting width 145mm, speed 0-40m/min

Slitting waste:10-25mm

3.Width tolerance:

≤±0.5mm thickness below 6mm

≤±0.8mm thickness below 6mm

Burr:≤5%

Camber: ≤0.8mm/2m;≤5mm/12m;

Coil diameter:ф760mm

Coil Max. O.D.:ф2000mm

Coil Max. weight:35T

Coil Max. thickness:16mm (Q235)

C, Other specifications

4, Our Service

5, Package And Delivery

6, FAQ