zhengzhou huaqiang heavy industry technology co., ltd. |

|

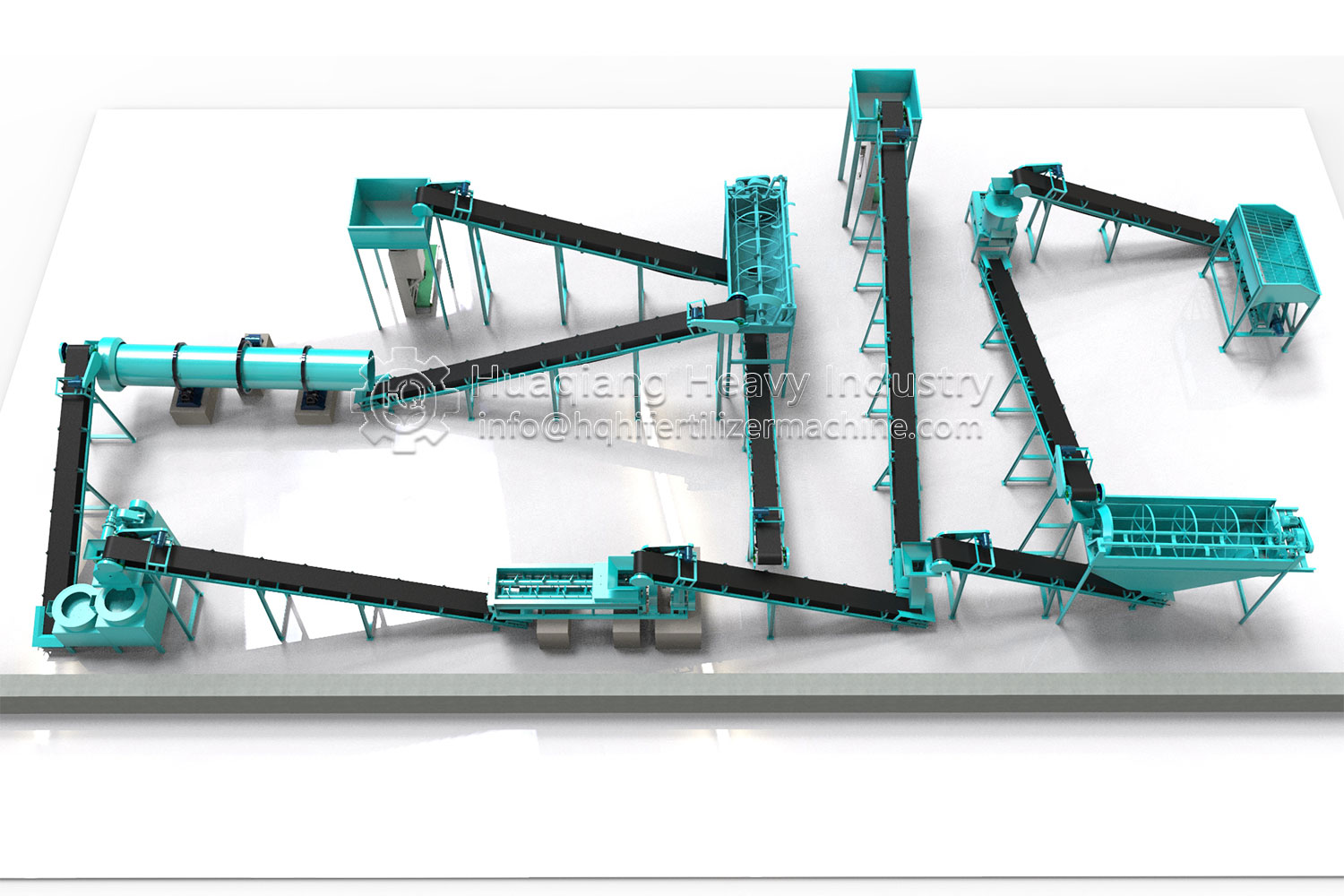

Poultry Dung Organic Waste Compost Fertilizer Pelletilizer

Production Machine Plant

Introduction of Poultry Dung Organic Waste Compost Fertilizer Pelletilizer

Production Machine Plant

Organic fertilizer production line is to process the organic raw

materials into the organic fertilizer that is derived from animal

waste, industrial waste, agriculture residue etc. It not only

reduces environment pollution, but also makes rational use of

resources.

Raw materials of Poultry Dung Organic Waste Compost Fertilizer Pelletilizer

Production Machine Plant

The cow dung, chicken manure and some other organic waste are good materials for making organic fertilizers. Forming an organic fertilizer production line, you can recycle these organic wastes in an economic way.

Making this fertilizer can improve the soil condition and soil fertility. If you fertilize the organic fertilizer, its organic matter will strengthen the soil fertility and buffer capacity. Thereupon, the soil condition will be better for plants growing.

Working Process of Poultry Dung Organic Waste Compost Fertilizer Pelletilizer

Production Machine Plant

Main equipment in Poultry Dung Organic Waste Compost Fertilizer Pelletilizer Production Machine Plant

| Number | Name | Function |

| 1 | Compost turning machine | Used for fermentation of organic fertilizer raw materials |

| 2 | Half wet materials crusher | Crushing high water content compost fertilizer |

| 3 | Mixer machine | Mixing organic fertilizer powder with other material or water |

| 4 | Organic fertilizer granulator | Making ball shape granules fertilizer |

| 5 | Dryer machine | After granulating, granules moisture is about 30%-40%, need to dry with hot air, this machine need to work with Burning Furnace to supply hot air. |

| 6 | Cooler machine | After drying, granules temperature is high with moisture, need to cool with air. |

| 7 | Screener machine | Separate different size granules, products go to packing machine. Oversize granules crush and re-granulate, small particles re-granulate. |

| 8 | Belt conveyor | Connect the machines in the line, have many types, like Belt conveyor, Screw conveyor, Bucket elevator etc... |

| 9 | Packing machine | Packing granules in bags, avalible 5-10kgs & 20-50kgs & 500-1000kgs |

| Auxiliary machines, optional | ||

| 10 | Burning furnace | Work with Dryer machine, burning fuel to supply hot air, fuel type:Coal/Natural gas/Wood/Diesel/Biogas etc... |

| 11 | Dust collector | 1.Client build the Dust collector room according to the drawing. 2.Use Cyclone Dust collector. To clean the air, prevent environment |

| 12 | Coating machine | Granules coating with auti-caking agent, slow release agent, Bacteria etc... |

| 13 | Installation accessories | Platform, Ladder, Stands etc... |

Features of Poultry Dung Organic Waste Compost Fertilizer Pelletilizer Production Machine Plant

1. Widely application. The organic fertilizer production line can process different kinds of raw materials, such as animal manure, agricultural waste, etc.

2. High quality, stable performance, easy to operate, highly automatic, long service life.

FAQ of Water Solubility Inoragnic NPK Fertilizer Pelletizer Production Line Plant

1.Terms of delivery:

A:EXW, FOB, CFR, CIF

2.How to choose the machines:

A:We have rich experience to help client design according to their requests, capacity, raw material, workshop size etc...

We have a professional technical team to meet the different requirements of clients. We can provide you the production line plan & solution, also give 3D and CAD drawings.

3.Delivery time:

A:According to the machines size and quantity, always 7-15 days. Large capacity line need about 30-40 days.

4.How to get spare parts:

A:Purchase from us, or we supply spare parts details, client can find or make in local.

5.What is the After-sale sevice?

a. Professional after-sales service personnel guide the customer

installation and commissioning at the site.

b. Train operators at site.

c. After the installation of the complete set of equipment,

technical personnel shall be left to assist the customer in field

production until the customer is satisfied.