ZHENGZHOU SHENGHONG HEAVY INDUSTRY TECHNOLOGY CO., LTD. |

|

Verified Suppliers

|

|

8-10T/H Fertilizer NPK 15-15-15 Compound Fertilizer Production Line

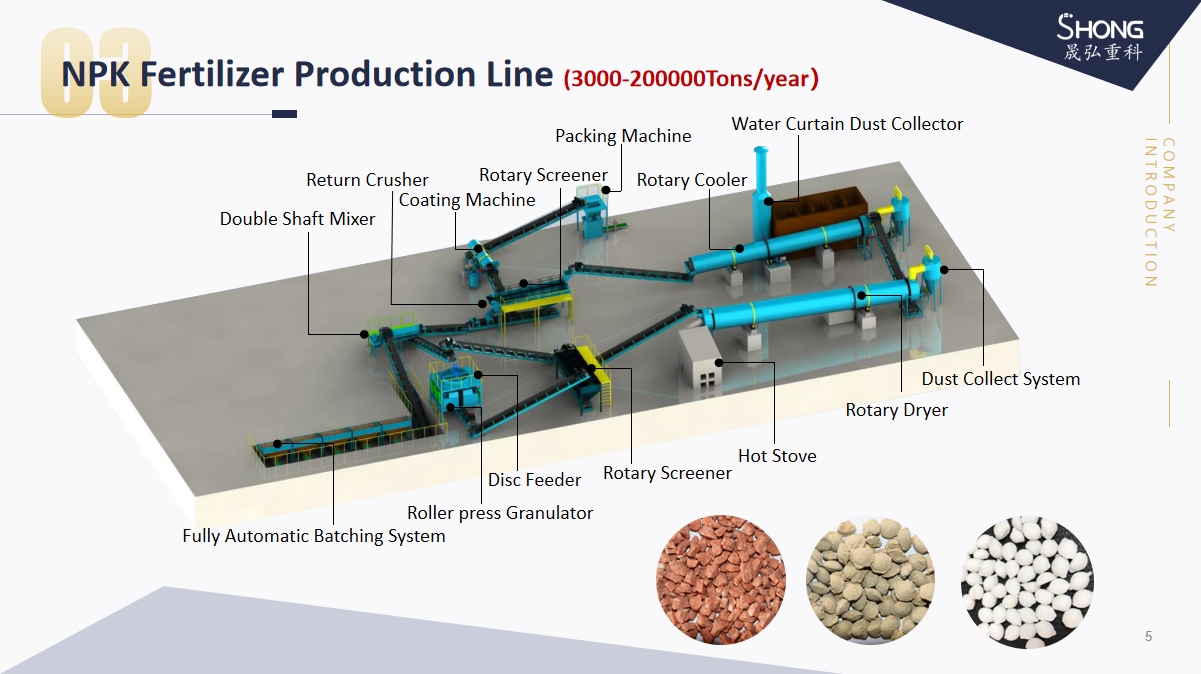

Introduction of NPK Fertilizer Production Line

NPK Compound fertilizer production line is widely applied to

produce compound fertilizer and the capacity ranges from

5000-200,000 tons/year. The process flow of the compound fertilizer

production line can be divided into: raw material ingredients, raw

material mixing, raw material granulation, particle drying,

granular cooling, particle grading, finished packaging film and

final product packaging.

Raw Material For NPK Compound Fertilizer Making Production Line

Compound fertilizer is the fertilizer containing two or all three of the three basic plant nutrients—Nitrogen, Phosphorus, and Potassium, as well as microelements, such as B, Mn, Cu, Zn, and Mo. The raw material can be powder or bulk, mostly are as below:

| Nitrogen | Phosphorus | Potassium | |

| Calcium nitrate | urea | Single superphosphate | Kainit |

| Ammonium bicarbonate | Ammonium chloride | Rock phosphate | Potassium chloride |

| Nitrate of soda | Ammonium sulphate nitrate | Dicalcium phosphate | Potassium sulphate |

| Ammonium sulphate | Ammonium nitrate | Triple superphosphate | Potassium nitrate |

Characteristics Of NPK Compound Fertilizer Making Production Line

The whole equipment process is compact, scientific and advanced.

Energy saving and consumption reducing, no waste removal, stable

operation, reliable running, convenient maintenance. The

adaptability of raw materials is wide, and the machine is suitable

for the granulation of compound fertilizer, medicine, chemical

industry, feed, etc., and the granulation rate is high.

The Process of NPK Fertilizer Production Line

1. Raw material ingredients: Urea, ammonium nitrate, ammonium

chloride, ammonium sulphate, ammonium phosphate (monoammonium

phosphate, diammonium phosphate, and coarse whiting, ca), potassium

chloride, potassium sulfate and other raw materials are matched in

proportion (according to the market demand and the around soil of

test results).

2. Raw materials mixing: The mixture of the ingredients should be

mixed to improve the uniform fertilizer efficiency of the granules.

3. Granulation of raw material: The raw material after mixing

equably will be sent to granulator (drum granulator, and extruding

granulator both can be used).

4. Granulation drying: put the granulation into the dryer, and the

moisture in the granules will be dried, so that the granulation

strength is increased and is easier to store.

5. Granulation cooling: After drying, the granulation’s temperature

is too high and the granulation is easy to lump. While after

cooling, it is easy to bagging to save and transport.

6. Particle classification: the cooling particles that have been

cooled will be graded: the unqualified particles will be crushed

and regranulated, and the qualified products will be sift out.

7. Finished film: The qualified products are coated to increase the

brightness and roundness of granules.

8. Packaging of finished product: The particles that have been

wrapped the film are stored in the ventilated place.

Working Principle of NPK Fertilizer Production Line

1. Granulation drying: put the granulation into the dryer, and the

moisture in the granules will be dried, so that the granulation

strength is increased and is easier to store.

2. Granulation cooling: After drying, the granulation’s temperature

is too high and the granulation is easy to lump. While after

cooling, it is easy to bagging to save and transport.

3. Particle classification: the cooling particles that have been

cooled will be graded: the unqualified particles will be crushed

and regranulated, and the qualified products will be sift out.

4. Raw material ingredients: Urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, and coarse whiting, ca), potassium chloride, potassium sulfate and other raw materials are matched in proportion (according to the market demand and the around soil of test results).

Features of NPK Fertilizer Production Line

A. transmission part adopts twoinput transfer mode, not only

improve input power ratio, but also ensure the lubrication and

sealing performance of transmission gear

B. stable operation,reliable operation,easy maintenance,wide raw

material adaptability

C. bearing bracket select excellent anticorrosion casting parts for

whole body, greatly improve service life of rolling bearing and

main shaft

D. granulating,molding,screening into one machine,make finished

product with good appearance,easy to operate

E. main components such as roller body adopts new type metal to

refine with anticorrosive, abrasion resistance, shock resistance

characteristics

F. transmission part adopts twoinput transfer mode, not only

improve input power ratio, but also ensure the lubrication and

sealing performance of transmission gear