Weifang Kaide Plastics Machinery Co., Ltd |

|

PA Nylone EVOH Oxygen Barrier Pipe With TPU Production Line

Multilayer Automobile PA Nylon Oil Tube Extrusion Machine

Below multilayer tube extrusion line is used to extrude 5 layer PA/EVOH automobile fule tube, with an outer diameter 6mm, 8mm and 10mm.

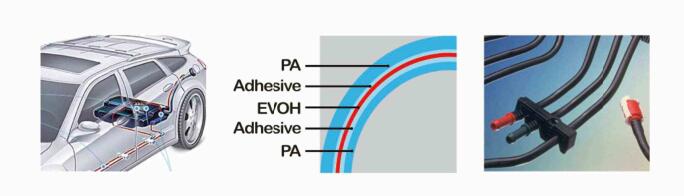

The PA multi-layer composite pipe can effectively reduce the automobile's emission pollution and meet higher enviromental requirements. As the multi-layer composite pipe features an excellent resistance to penetration, it meets EU-III standards.

Multilayer Pipe Structure:

TECHNICAL DATA

| lINE Model | Screw diameter | Production Scope | Production Speed |

|---|---|---|---|

| KDFPA-45 | 45/45/30mm | 6-20mm | 40m/min |

| KDFPA-65 | 65/45/30mm | 6-20mm | 80m/min |

MULTILAYER AUTOMOBILE FUEL PIPE MACHINE

MORE INFORMATION NEEDED,

PLS CONTACT US RIGHT NOW!!