ROSCHEN GROUP |

|

Verified Suppliers

|

|

Commander PDC bits Used Dark Matter Cutters High Penetration Drilling Deeper Holes

Commander PDC bits offer improved directional control and

steerability at a higher rate of penetration. DARK MATTER cutters

stand up better to drilling the deeper holes at longer intervals

due to high thermal resistance.

PDC gray face

Standard bits can be easily disrupted by the dynamic instabilities

of directional or lateral drilling, but Atlas Copco Secoroc

COMMANDER PDC bits feature a patented discontinuous seven-blade bit

design to address these factors with improved performance.

Finding a bit that offers both good steerability and good ROP can

be a difficult proposal. In theory, more blades offer more

stability and by extension better ability to control and steer the

bit. However, more blades typically also means more cutter contact

with the formation, which equates to slower drilling. The curve and

lateral sections of a well can cause drillers to reduce the rate of

penetration (ROP) to preserve the tool face or risk having to trip

out of the hole. Standard PDC inserts with their high

abrasion-resistant cutting edges may be suitable for a number of

oilfield applications in general. In applications that generate

higher heat, however, the cobalt present in a standard PDC insert

acts as a catalyst to sinter the diamond-to-diamond bond, unitizing

the diamond layer to the tungsten carbide substrate.

Roschen used proprietary software to model how the bits function

under a variety of drilling challenges such as rotating off center

axis and abnormal force absorption. COMMANDER PDC Bit Series

demonstrated up to 35 percent improvement in stability in off

center axis drilling situations with a 29 percent improvement in

stability for abnormal force absorption.

Heat generated by friction during the drilling process can causes

cobalt in the cutters to expand at a higher rate than diamond.

Thermal stress in the diamond table increases until the structure

breaks down. The cobalt between the diamond crystals expands and

breaks the diamond-to-diamond bonds. The result is reduced cutter

life and premature cutter failure.

Patent protected deep-leaching technology selectively removes

cobalt from the diamond table of the PDC cutter. Leaching increases

cutter thermal stability, which reduces damage to the cutter and

extending bit life in difficult and abrasive formations.

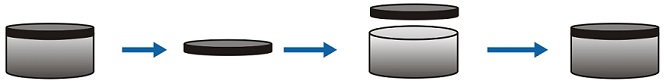

Starting with a standard cutter, the diamond table is removed from

the substrate. The substrate is discarded and cobalt is removed

from the diamond table. The diamond table is then attached to a new

substrate. The resulting PDC cutter is deep leached, removing

infiltrated cobalt to several hundred microns.

| NO. | ROCK BIT SIZE | REG.PIN API | |

| in | mm | ||

| 1 | 3 3/4 | 95.3 | 2 3/8 |

| 2 | 3 7/8 | 98.4 | 2 3/8 |

| 3 | 4 1/8 | 104.8 | 2 3/8 |

| 4 | 4 1/4 | 108 | 2 3/8 |

| 5 | 4 1/2 | 114.3 | 2 3/8 |

| 6 | 4 5/8 | 117.5 | 2 7/8 |

| 7 | 4 3/4 | 120.7 | 2 7/8 |

| 8 | 4 7/8 | 123.8 | 2 7/8 |

| 9 | 5 1/2 | 139.7 | 3 1/2 |

| 10 | 5 5/8 | 142.9 | 3 1/2 |

| 11 | 5 2/3 | 143.9 | 3 1/2 |

| 12 | 4 3/4 | 146.1 | 3 1/2 |

| 13 | 5 7/8 | 149.2 | 3 1/2 |

| 14 | 6 | 152.4 | 3 1/2 |

| 15 | 6 1/8 | 155.6 | 3 1/2 |

| 16 | 6 1/4 | 158.8 | 3 1/2 |

| 17 | 6 1/2 | 165.1 | 3 1/2 |

| 18 | 6 5/8 | 168.3 | 3 1/2 |

| 19 | 6 3/4 | 171.5 | 3 1/2 |

| 20 | 7 1/2 | 190.5 | 4 1/2 |

| 21 | 7 5/8 | 193.7 | 4 1/2 |

| 22 | 7 7/8 | 200 | 4 1/2 |

| 23 | 8 3/8 | 212.7 | 4 1/2 |

| 24 | 8 1/2 | 215.9 | 4 1/2 |

| 25 | 8 5/8 | 219.1 | 4 1/2 |

| 26 | 8 3/4 | 222.3 | 4 1/2 |

| 27 | 9 1/2 | 241.3 | 6 5/8 |

| 28 | 9 5/8 | 244.5 | 6 5/8 |

| 29 | 9 7/8 | 250.8 | 6 5/8 |

| 30 | 10 1/2 | 266.7 | 6 5/8 |

| 31 | 10 5/8 | 269.9 | 6 5/8 |

| 32 | 11 | 279.4 | 6 5/8 |

| 33 | 11 5/8 | 295.3 | 6 5/8 |

| 34 | 12 | 304.8 | 6 5/8 |

| 35 | 12 1/4 | 311.2 | 6 5/8 |

| 36 | 12 5/16 | 312.7 | 6 5/8 |

| 37 | 13 3/8 | 314.3 | 6 5/8 |

| 38 | 12 7/16 | 315.9 | 6 5/8 |

| 39 | 12 5/8 | 320.7 | 6 5/8 |

| 40 | 13 1/8 | 333.4 | 6 5/8 |

| 41 | 13 1/2 | 342.9 | 6 5/8 |

| 42 | 13 5/8 | 346.1 | 6 5/8 |

| 43 | 13 3/4 | 349.3 | 6 5/8 |

| 44 | 14 1/2 | 368.3 | 7 5/8 |

| 45 | 14 3/4 | 374.7 | 7 5/8 |

| 46 | 15 1/2 | 393.7 | 7 5/8 |

| 47 | 16 | 406.4 | 7 5/8 |

| 48 | 17 1/2 | 444.5 | 7 5/8 |

| 49 | 18 7/8 | 479.4 | 7 5/8 |

| 50 | 20 | 508 | 7 5/8 |

| 51 | 22 | 558.8 | 7 5/8 |

| 52 | 24 | 609.6 | 7 5/8 |

| 53 | 26 | 660.4 | 7 5/8 |

| 54 | 28 | 711.2 | 7 5/8 |

| 55 | 30 | 762 | 7 5/8 |

Please contact:

ROSCHEN GROUP LIMITED

Skype: ROSCHEN.TOOL , ROSCHEN_GROUP

WeChat: +86-137 6419 5009 ; +86-135 8585 5390

WhatsApp: +86-137 6419 5009 ; +86-135 8585 5390

Email: roschen@roschen.com ; roschen@roschen.net

Website: http://www.roschen.com ; http://www.roschen.net

Key words:

COMMANDER Bits / DARK MATTER Cutters

Deep Leach Technology from Atlas Copco

COMMANDER Bits / DARK MATTER Cutters

Deep Leach Technology from Atlas Copco

pdc drill bit manufacturers

pdc drill bit companies

pdc drill bits for sale

pdc drilling

nov pdc bit

pdc drill bit repair

pdc bit sizes

pcd bit

pdc bit companies

pdc bit manufacturers

pdc bit definition

pdc bit sizes

nov pdc bit

diamond pdc bit

pdc bits for sale

pdc cutters