ROSCHEN GROUP |

|

Verified Suppliers

|

|

Gardner-Denver Universal Jumbo Twin Boom Drill

Gardner-Denver Universal Jumbo Twin Boom Drill Rig for drilling

parallel holes

Gardner-Denver Universal Jumbo Twin Boom Drill Rig for drilling

parallel holes

Versatility

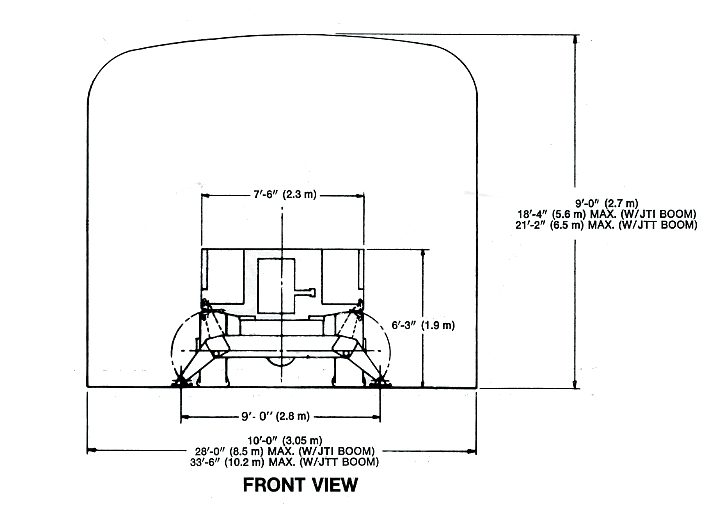

The Gardner-Denver Jumbo is a multi-purpose machine, and is not

restricted to only one function, such as drilling parallel holes.

The Universal, as the name implies, drills burn cuts, V-cuts, cross

cuts, stopes, rock-bolt holes, etc.

Ruggedness

The heavy-duty undercarriage features a one piece rigid structural

frame, heavy-duty planetary axles, low pressure wide tires.

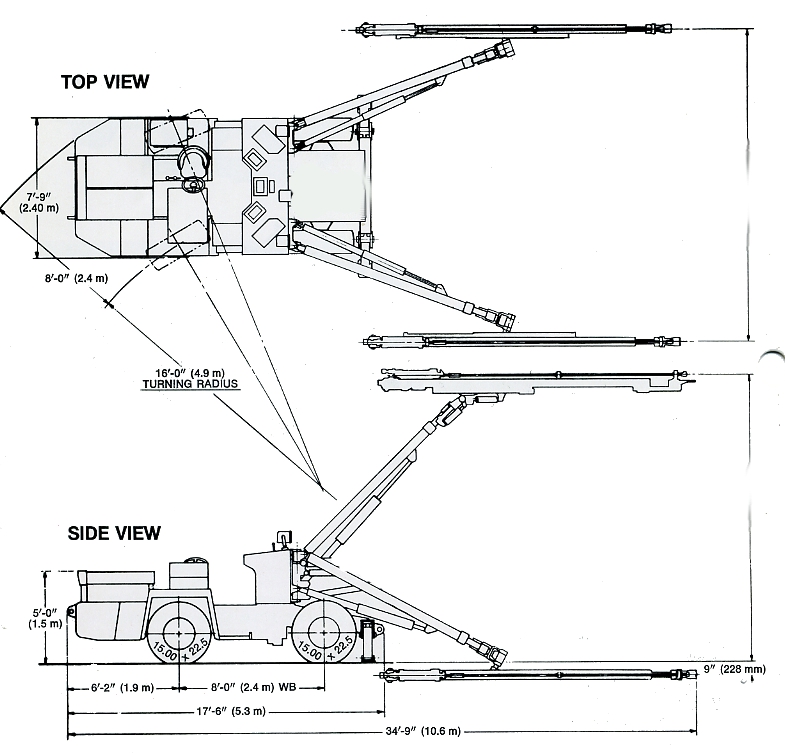

Maneuverability

A highly efficient power steering combined with short wheel base,

reduces the turn radius to a minimum. Automotive type steering that

allows the Jumbo to tram close to the wall, without fear of

"locking side" as in case of articulated steering. The compactness,

low profile and operator side seating feature permits the machine

to negotiate headings as small as 10' (3.05 m) wide x 9' (2.7 m)

high.

Highly mobile, highly flexible, the Universal Jumbo uses the

building block design to give you the combination of components and

options you want. And as the conditions and assignments change so

can the Jumbo.

This basic drill carriage can be put to a number of mining tasks by

assembling various combinations of engineered "building block"

components.

WEIGHTS ● SPECIFICATIONS ● DIMENSIONS

Standard Universal Jumbo Components List:

1. Heavy Duty Undercarriage

2. Control Console and Counterweights

3. Hydraulic Outriggers

4. Model JHPU Hydraulic Pump

5. Model 1028560 Remote Drill Controls

6. Model 154200 10 Gallon Rock Oil Lubricator Reservoir

7. Drilling Equipment

Two Model JTI Rota-Booms:

1. Two Model DPT Positioners, 5' feed extension

2. Two Model 2MSM120R Feeds

3. Two Model PR55 Drills

Design Features and Specifications:

1. 4-Wheel drive.

2. Power steering.

3. Power brakes.

4. Deutz Model F620912 W Air Cooled Diesel Engine.

5. 4-speed forward/reverse transmission with optional speed ranges.

6. Drilling floodlights in vibration resistant fixtures.

7. Carrier tramming lights.

8. Operator's console with valves grouped for convenient operation.

9. Swing-out type hydraulic valve mountings for access to fittings.

10.Side seating.

11. Choice of water batch or oxy-catalyst, U.S.B.M. approved.

12. Rotary air valves for precise regulation and throttling of feed

and drill.

13. Pressure regulated feed valves for varying ground conditions.

14. Air and hydraulic pressure gauges with protective covers.

15. 15:00 x 22.5 HRL Tires

16. 10-gallon (37.8 lit.) capacity lubricating oil tank, with

individual regulation of oil flow to drills, feeds and air motors

17. Hydraulic Outriggers

18. Hydraulic power always available from diesel engine or external

air supply.

19. Maximum speed 4.2 M.P.H. (7.4 km/hr.).

20. Gradeability - 35%.

21. Approximate operating weight - 32,000 lbs. (14,500 kg.).

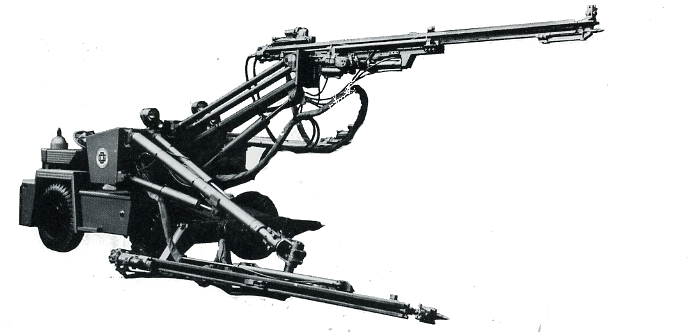

JT144/DPT

Boom and Positioner Combination

Technical Parameters:

1. JTI-DPT Boom and Positioner Combination is a roll-over-type Boom

for full face coverage

2. 360º rollover capability; full-circle coverage pattern;

eliminates blind spots

3. Rotation in both directions allows the hose harness to be kept

clear from damage or twisting

4. Rollover reaches the lower toe holes at the bottom of the tunnel

face

5. Completely enclosed rotation mechanism prevents debris from

jamming the Boom

6. A wide RANGE of drilling components, feeds, and drills can be

mounted on the Boom; choice of right or left hand mounting;

vertical or horizontal bracket

7. Hydraulically operated, easily controlled; for swift and

POSITIVE positioning all cylinders include checkvalves to LOCK the

boom in set position in the event of power loss or hydraulic fluid

leakage

8. Drill positioner can be REMOVED from the the boom; replacement

by stock units reduces costly downtime and assists maintenance

programs

9. Rigid construction; provides a RIGID mounting for feed and drill

components; PRECISE drilling; reduces wear; mounts longer feeds and

larger drills

10. Simple maintenance; all swivel joints are easily lubricated or

REPLACEABLE; insure maximum SERVICE life of major components

11. Multiple Booms; several units can be combined on a single jumbo

rig to provide a MAXIMUM coverage pattern.

The JTI 144 Boom and DPT Positioner used as a combination unit

result inthese maximum overall equipment capacities.

Boom Pivot Point in the front view of the mounting bracket is shown

as seenfrom the drilling face looking at the base of the Boom.

JTI-DPT Coverage pattern as seen from the base of the Boom looking

at thedrilling face. This coverage pattern shows maximum

parallel-hole drilling withan aluminum shell screw feed and a

standard drifter drill. (Each square = 1foot or 305 mm)

| TABLE OF WEIGHTS | |||

| JTI Boom & DPT Positioner without a Feed Extension | JTI Boom & DPT Positioner with a 2 ft. (.61 m) Feed Extension | JTI Boom & DPT Positioner with a 3 ft. (.91 m) Feed Extension | JTI Boom & DPT Positioner with a 5 ft. (1.5 m) Feed Extension |

| 2207 lbs | 2185 lbs | 2283 lbs | 2305 lbs |

| 1001 kg | 991 kg | 1036 kg | 1046 kg |

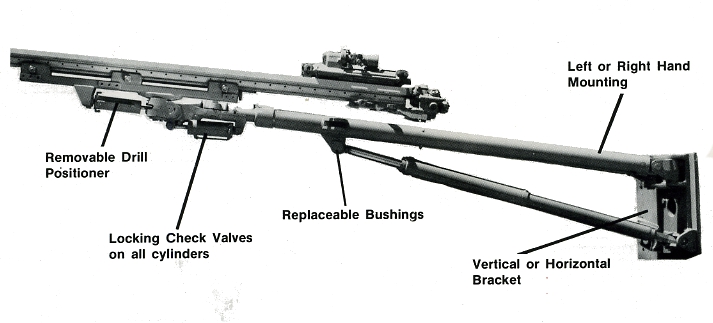

2MSB SERIES

Screw Feeds

for Underground Jumbos

Drilling Features:

Rugged Construction

Strong, extra-high web, wide-way Guide Shell

and 1-1/2 H.P. In-Line Motor provide dependable service...High

strength, light weight aluminum shell.

Remote Controls or Integral Control Valve Option

The radial piston Feed Motor provides a very

accurately controlled feed pressure. Choose the remote control

style or the integral control Valve and Handle right on the Motor.

Fast Drill return speed in reverse control.

Exact Drill Travel Lengths

Full range of Shell-and-Screw lengths to

provide the exact Drill travel needed for every drilling operation.

Low Maintenance

Provided by Gardner-Denver quality design in

all Bearings, Seals, Bumpers, and Fasteners plus built-in gear

lubrication oil chamber.

Wide Range of Gardner-Denver Modular Drilling Equipment:

1. Aluminum Shell Screw Feed and Motor

2. Power Centralizers

3. Wide range of Drill models

4. Sectional Drill Rod equipment in many sizes

5. Integral one-pass Drill Rods

6. Versatile Remote Control Valve units

7. Automated push-button drilling cycle Controls

8. All types of Positioners, Booms, and mounting systems

Technical Parameters:

| 2MSB Series MODEL NO. 2MSB144 | L | T | Weight of Mounting | Boxed Shipping Dimensions | Boxed Shipping Weight | |||||

| Overall Length of Mounting Only | Typical Travel Length | |||||||||

| U.S. Inches | Metric mm | U.S. Inches | Metric mm | U.S. Lbs. | Metric kg | U.S. Inches | Metric mm | U.S. Lbs. | Metric kg | |

| 183 | 4648 | 145 | 3683 | 328 | 148.8 | 14x17x193 | 356x432x4902 | 485 | 220 | |

Surface Drill:

1. Plastic Water Tube

2. Nonstellited Ways

3. Closed Chuck End

Features:

1. Rotation Air Motor with 10-1 gear reduction, Stall Torque 250

ft. lbs.

2. Friction Free Bearings

3. Reversible bronze Chuck

4. Positive Pressurized Chuck End

5. Replaceable Ways

6. Integral Muffle

7. Side Exhaust or alternate

Top-Bottom Exhaust, 111 dBa at 1 meter at 90 psi (621 kPa)

8.Double supported reversible Hammer

Specifications:

1. Bore

5.5" Diam.

139 mm

2. Hole Size Range

1-1/2" - 3-1/2" Diam.

38 mm - 89 mm Diam.

3. Weight

320 lbs.

145 kg

4. Hoses

Hammer Air - 1-1/2" I.D., 38 mm

Rotation Air - 1" I.D., 25 mm

Blow Air or Water 3/4" I.D., 19 mm

5. Drill Rod

1. 1-1/4" Hex - 32 mm

2. 1-1/4" Rd., 32 mm

3. 1" Q.O., 25 mm

4. 1" Hex, 25 mm

For more information please contact:

ROSCHEN INC.

ROSCHEN GROUP LIMITED

ROSCHEN HOLDINGS LIMITED

Skype: ROSCHEN.TOOL , ROSCHEN_GROUP

WeChat: +86-137 6419 5009 ; +86-135 8585 5390

WhatsApp: +86-137 6419 5009 ; +86-135 8585 5390

Email: roschen@roschen.com ; roschen@roschen.net

Website: http://www.roschen.net ; http://www.roschen.cn

http://www.roschen.com ; http://www.roschengroup.com