Kaiping Zhonghe Machinery Manufacturing Co., Ltd |

|

Verified Suppliers

|

|

2024 Zhonghe Machinery Catalogue 3M.pdf

Introduction:

Excavators are versatile heavy machinery used in construction,

mining, and other industries. They are equipped with various

attachments to perform specific tasks efficiently. One essential

attachment is the compacting wheel, which offers several advantages

in the construction process. This article will highlight the key

benefits of using compacting wheels in excavators.

Efficient Soil Compaction:

Compacting wheels are specifically designed to compress soil and

enhance its stability. By utilizing the weight and force of the

excavator, the compacting wheel exerts significant pressure on the

ground, resulting in improved compaction. This process ensures a

solid foundation for subsequent construction activities, such as

road paving or building construction.

Versatility:

Compact wheels in excavators are adaptable to different soil types

and terrains. They can efficiently compact various materials,

including gravel, sand, clay, and even asphalt. The ability to work

on diverse surfaces makes compacting wheels invaluable in a wide

range of construction projects, from road construction to

landscaping.

Time and Cost Savings:

By integrating a compacting wheel into an excavator, construction

projects can save time and reduce costs. Traditional compacting

methods often require separate equipment and additional manpower.

With the compacting wheel attached to the excavator, soil

compaction can be carried out simultaneously during excavation,

eliminating the need for separate compaction equipment and reducing

labor requirements.

Increased Productivity:

The integration of a compacting wheel enhances the overall

productivity of an excavator. Since the compaction process is

integrated with the excavation process, there is no need for

downtime or interruptions between these two activities. This

seamless integration allows for a continuous workflow, reducing

project timelines and increasing overall productivity.

Precise and Controlled Compaction:

Compact wheels offer precise control over the compaction process.

Operators can adjust the pressure and speed of the compacting wheel

to achieve the desired compaction level for different soil

conditions. The ability to control the compaction process ensures

uniformity and consistency across the construction site, resulting

in a more stable and reliable foundation.

Improved Safety:

Using compacting wheels in excavators enhances safety on

construction sites. Traditional methods, such as using separate

compactors, may involve additional movement of heavy machinery,

increasing the risk of accidents. With the compacting wheel

integrated into the excavator, there is reduced machinery movement,

minimizing the chances of collisions and improving overall site

safety.

More excavator bucket as below:

Apart from the Standard bucket, Rocky bucket and Heavy duty bucket,

Doozer also offering special

purpose bucket, such as Tilt bucket, Ripper, Grab, Quick coupler, V

Drain bucket, Mud bucket, Dustpan

bucket, Clamshell bucket, Skeleton bucket, Ripper bucket, etc.

Packing of Rock bucket

International standard pallet or wood case.

1. one 20GP can load about 12-14 pieces 1.0m3 or 1.2m3 buckets for

20ton excavator(Width less than 42 inches )

2. one 40HC can load about 26-28 pieces 1.0m3 or 1.2m3 buckets for

20ton excavator;

3. one 20GP can load about 8 pieces 1.6m3 buckets for 30ton

excavator;

4. one 40HC can load about 16 pieces 1.6m3 buckets for 30ton

excavator.

We take part in Changsha Construction Machinery Exhibition

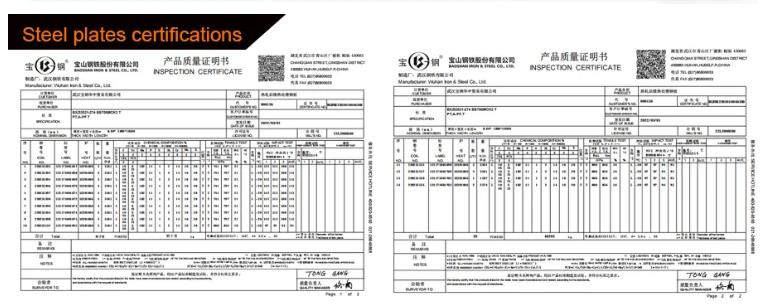

Certification of Rock bucket