Sinuo Testing Equipment Co. , Limited |

|

Verified Suppliers

|

|

ASTM B117 Comprehensive Cyclic Salt Spray Corrosion Test Chamber

Complied Standards & Clauses

This comprehensive salt spray test chamber can perform neutral salt spray test (NSS), acetic acid salt spray test (ASS), copper accelerated acetic acid salt spray test (CASS) according to, GB/T10125-2012, ASTM B117-2002, BS7479:1991, cyclic corrosion test can also be carried out according to GM9540P, PV1210 and other standards.

This test chamber meets the requirements of ES 5454, GJB150A, ASTM B117, ASTM B368, ASTM B380, ASTM D1735, ASTM D2247, ASTM G85 A1, GM4465P, ISO9227, DIN 50021, PV1210, NES M0007, 33 (CCT-1 method),etc.

Technical Parameters

| Internal dimensions | 1500mm x 800mm x 800mm (L×W×H) Can be customized |

| Temperature range | Sample room: -70℃~+180℃ controllable Saturation barrel: room temperature~+70℃ controllable |

| Temperature uniformity | ≤±2℃. |

| Temperature fluctuation | ≤±1.0℃. |

| Humidity range | 10%~95%R.H |

| Humidity deviation | +2, -3% RH |

| Salt spray deposition | 1ml/h~2 ml/ 80cm2/h |

| Spray method | Pneumatic, continuous and intermittent spraying can be switched. |

| Center angle | 110~120° |

| Ambient temperature | 0 ~ 35℃. |

Equipment Overview

This system is composed of conditioning chamber, dry heater, evaporator (refrigeration), humidifier extension pipe, centrifugal fan, etc. The purpose is to adjust the dry temperature and humid air in the conditioning chamber after sufficient mixing, and sent into the working chamber, enter into the return air vent, sent back to the adjustment cavity to continue the cycle, repeating the cycle.

Adopting the air-flow spray method and the principle of siphon, the absorbed salt solution is atomized through the nozzle, and the atomization particle size is uniform, which can ensure the continuity and stability of the test.

Use environment:

| power supply | AC380V 50Hz: The allowable voltage fluctuation range is AC(380±20) V; The allowable frequency range of wave motion is (50±0.5)Hz. |

| Environmental conditions | Allowable use temperature range: 0℃ -30 ℃; Performance guarantee range: + 5℃ ~ + 20℃; Relative humidity: ≤90%RH. |

| Air source | above 0.4Mpa |

| Site | The ground is flat and well ventilated; proper use and maintenance space is reserved. |

Accessories:

| Name | Note |

| Measuring cylinders | 2 units |

| Glass thermometers | 2 units |

| Standard 80cm2 salt mist collection device | 2 sets |

| Non-crystallization glass nozzles | 2 units |

| Wet bulb cup | 1 unit |

| Quick mist exhaust system | 1 set |

| Sodium Chloride (nacl) 500g/bottle | 6 bottles |

Chamber features

1. The main structure of the test chamber:

1.1 Test chamber body: The whole is made of SUS316 stainless steel plate, the thickness is 1MM, high temperature resistance, acid and alkali resistance. Sealed door of laboratory, neat and beautiful appearance

1.2 Salt solution replenishment tank: a water level perspective window is attached. Easy to clean, easy to observe the water level of the solution, convenient to replenish the salt solution at any time.

1.3 Saturation barrel: SUS304 stainless steel barrel, with high temperature resistance and high pressure resistance, and provides the same humid air as the inside of the chamber.

1.4 Laboratory sample rack: V-shaped bracket is made of PP board slotted processing, 0-shaped suspension bracket is made of glass fiber rod, which is corrosion-resistant and load-bearing. The article can be placed a large number of specimens, can also be adjusted 15°, 30° for placing test plates.

1.5 The humidifier tube of the humidifier barrel is imported into the studio, and then the fan of the studio is used to stir evenly. Humidity is expressed in terms of dry and wet bulb temperature.

1.6 Air conditioning system: This system is composed of conditioning chamber, dry heater, evaporator (refrigeration), humidifier extension pipe, centrifugal fan, etc. The purpose is to adjust the dry temperature and humid air in the conditioning chamber after sufficient mixing, and sent into the working chamber, into the return air vent, sent back to the adjustment chamber to continue the cycle, repeating the cycle.

1.7 chamber cover: It has sufficient strength and rigidity to observe the spray status. The chamber cover is opened and closed by pneumatic struts, which is convenient and free. Adopt a water-sealed structure to ensure that the salt spray does not overflow. The cover is automatically protected when it is opened, and the cyclic corrosion test is automatically started from the break point after the cover is closed. The cover uses an angle of 110º ~ 120º to ensure that the condensed water does not drip on the test piece.

1.8 Equilibrium exhaust holes are provided to prevent the pressure in the chamber from rising, so that the air flow in the working space is not excessively disturbed when exhausting.

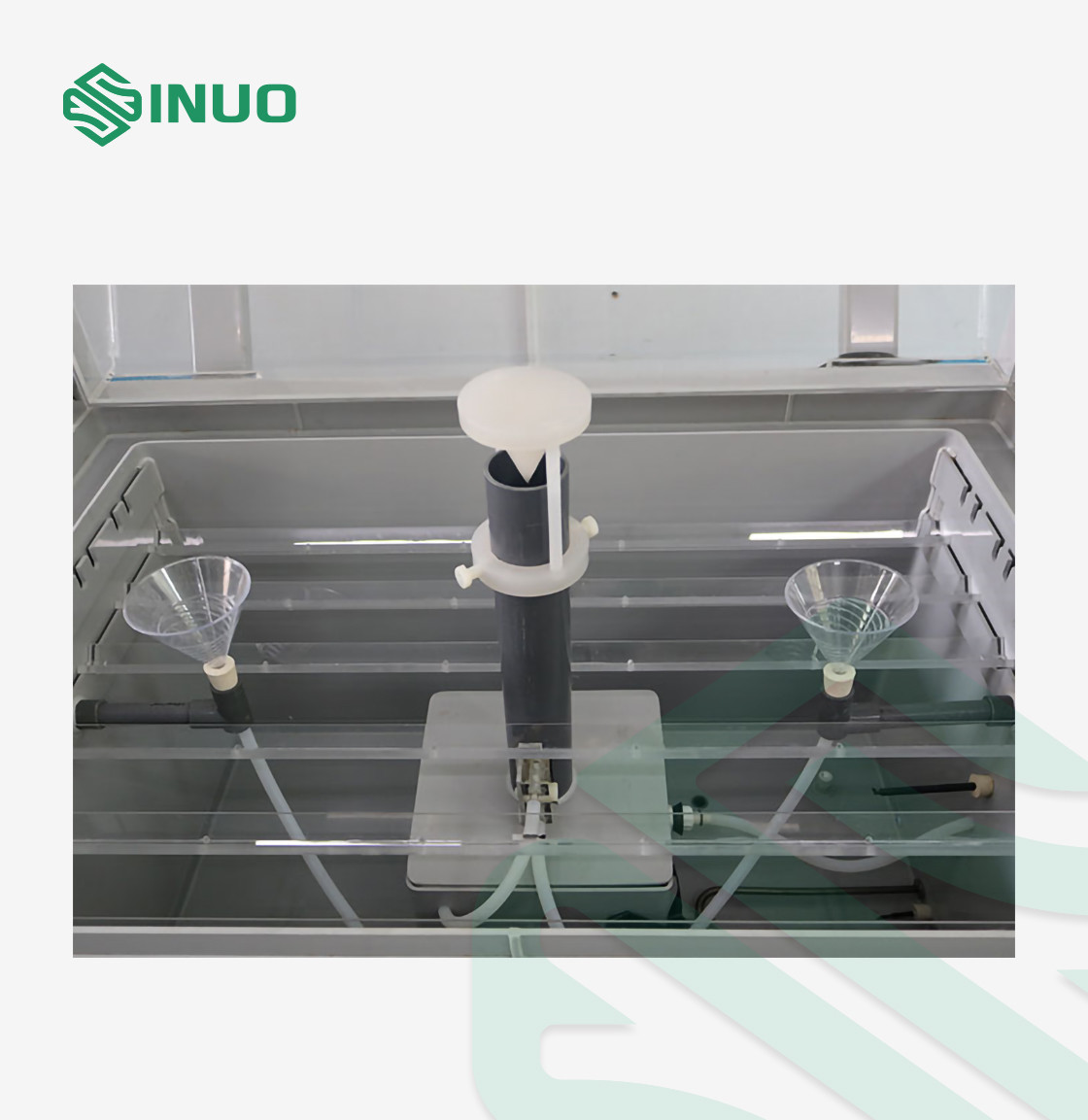

1.9 Equipped with a graduated separatory funnel to collect and visualize the precipitation of salt spray outside the chamber.

1.10 There are two spray towers, which can meet the demand for salt fog precipitation more evenly and faster.

1.11 There is an automatic water replenishment system, which will automatically replenish water when the water level is too low.

2. Three Gas supply system:

2.1 The air source is supplied by the air produced by the air compressor (provided by the customer), which is purified and filtered by the first-level air, and the second-level air pressure is adjusted before being sent into the saturated tank.

2.2 This test chamber is equipped with two air pressure regulating valves. When the air pressure provided by the air compressor is connected, the pressure of the first pressure regulating valve entering the gas pipeline should be adjusted to 0.2Mpa

2.3 The second pressure regulating valve (that is, the regulating valve that regulates the spray pressure) entering the nozzle, the pressure should be adjusted to between 0.07 and 0.1 MPa.

2.4 Pneumatic system: stable and reliable imported pneumatic components.

3. Spray system: the nozzle can be detached for easy cleaning

3.1 Adopt the air-flow spray method and use the principle of siphon to atomize the absorbed salt solution through the nozzle, and the atomization particle size is uniform, which can ensure the continuity and stability of the test.

3.2 It adopts non-crystal nozzle and baffle spray device. After spreading through the baffle, it falls uniformly and freely in the test chamber, so that the precipitation of the salt spray reaches the specified value.

3.3 The brine before spraying is injected into the preheating tank through the brine storage tank, preheated and then introduced into the nozzle. The temperature fluctuation of the working room after the constant temperature is smaller.

3.4 The amount of salt spray deposition: According to the size of the nozzle pressure 1-2 ml/80cm2/hr (16hr average), the ¢ angle of the baffle plate can be adjusted to control the amount of salt spray, so that the amount of salt fog can reach 1- 2ml/cm2·h.

3.5 The spray pressure can be adjusted to 0.8-1.MPa.

4. Refrigeration system:

The design of the refrigeration system applies energy regulation technology, which can ensure the normal operation of the refrigeration unit.

It can also effectively adjust the energy consumption and cooling capacity of the refrigeration system to keep the refrigeration system in the best operating state. Using the Balanced Temperature and Humidity Control (BTHC) method, in the case of continuous operation of the refrigeration system, the control system controls the output of the heater through the PID automatic calculation output according to the set temperature point, and finally achieves a dynamic balance.

4.1 Condenser: air-cooled condenser.

4.2 Evaporator: finned heat exchanger.

4.3 Solenoid valve: Omron.

5. Control system:

5.1 Temperature and humidity controller

● Display: 7-inch color LCD display. Operation mode: fixed value or program.

● Setting method: English menu, touch screen interactive interface input. Program capacity: 120 groups and 1200 test programs can be stored.

● Program length: each group of programs can have 99 segments at most. Cycle times: each program segment can be cycled 999 times.

● Setting range:

△Temperature: -100℃~+200℃,

△Humidity: 0~100%RH,

△Time: 0~99 hours and 59 minutes.

● Resolution: temperature: 0.1℃, humidity: 0.1%RH, time: 0.1min.

● Input: PT100 platinum resistance.

● Communication function: This controller is equipped with RS232/485 interface (optionally equipped with USB interface model controller, which can export and store data).

● Other functions: The equipment has multiple alarm protection functions such as over-temperature, fan over-heating, over-current, etc. The fault self-diagnosis function of the controller can ensure that once the equipment is abnormal, the power supply of the main components will be cut off and an alarm signal will be sent at the same time.

5.2. Measurement data collection: PT100 platinum resistance.

5.3. Other executive components: French "Schneider" AC contactors, switches, buttons, Omron small relays and other famous brand products.

5.4 Safety temperature controller for liquid expansion of heating tank 0-120℃.

5.5 Saturated air tank liquid expansion safety temperature controller 0-120℃.

5.6 Precise adjustment of primary pressure: air filter included.

5.7 Pressure gauge: 5kg/cm2

6. Safety protection device:

6.1 Automatically cut off the power supply device when the water level is low

6.2 Over-temperature automatic power-off device

6.3 Sound and light alarm device

6.4 Saturated tank over-temperature protection

6.5 Low water level warning device of salt liquid

6.6 Overpressure alarm of refrigeration compressor

6.7 Pure water level sign and lack of alarm