Shenzhen Fairtech Electronics Co.,LTD |

|

Verified Suppliers

|

|

ESD clothing made with FairtechTextiles fabrics is the best solution for protecting electronic components against ESD. Our Anti Static fabrics are certified to European Standards. These antistatic fabrics are specifically designed to prevent the ESD effect when working with electronics, high-explosive vapors, or in super-clean lab environments.

Antistatic fabric, also known as conductive fabric or ESD (Electrostatic Discharge) fabric, is a type of textile that is designed to dissipate or neutralize static electricity. It is commonly used in industries where static electricity can cause damage to sensitive electronic components or create safety hazards. Here's some information about antistatic fabric:

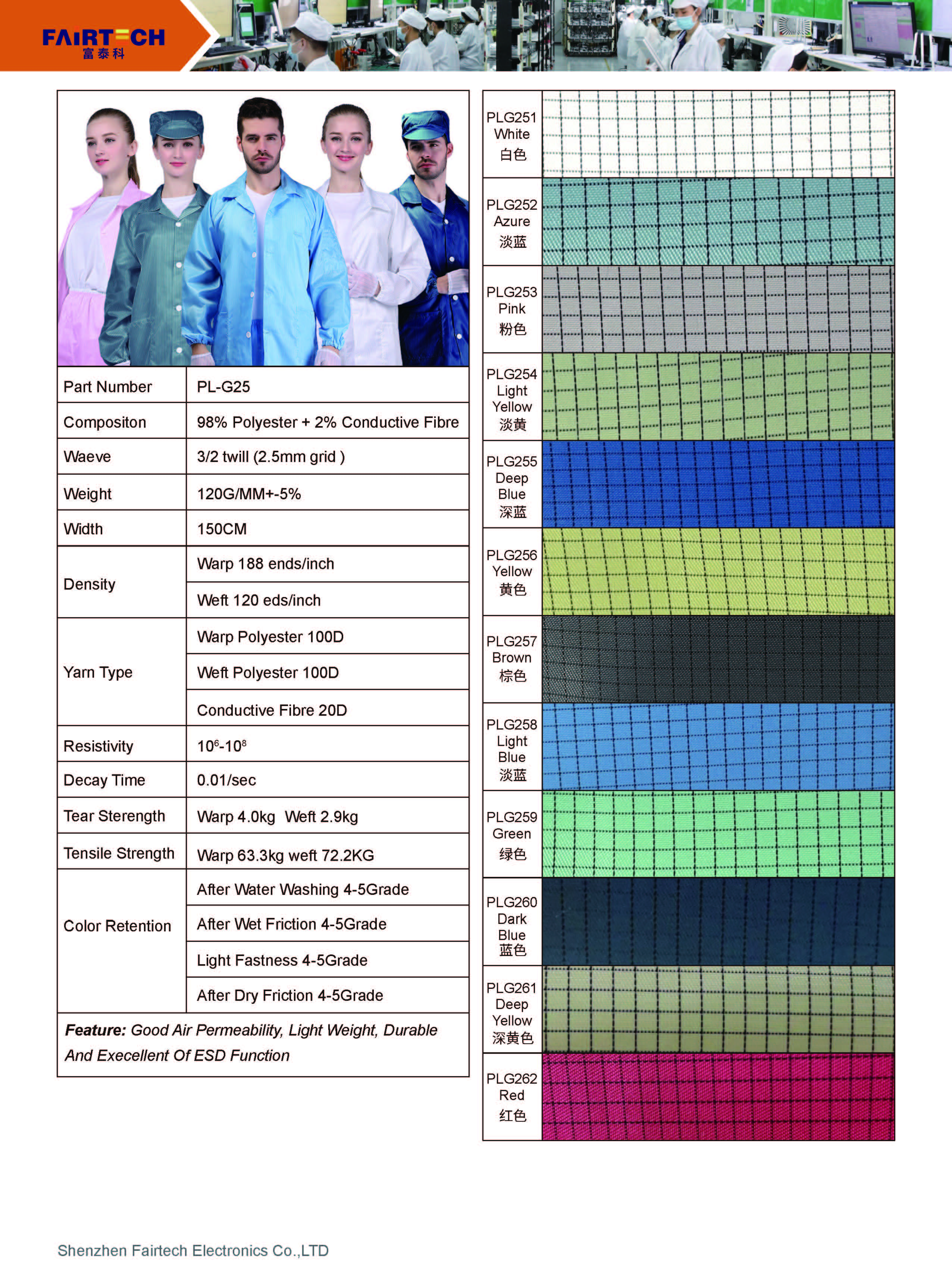

Anti-static cloth styles: 5mm strip, 5mm grid and 2.5mm grid. It is mainly used in the production of dust-proof clothing, anti-static clothing, anti-static mask, anti-static gloves, anti-static shoe and shoes cover. The fabric is 1.5m wide, surface resistance 10^6Ω-10^9Ω, available for class 10-100 cleanroom. Different type of fabric adapts to the requirements of different anti static or cleanroom environment. It is widely used in Microelectronics, optical electronics, precision instruments, and aerospace which are more sensitive to static electricity and have higher requirements in cleanroom.

Why we need the Anti static fabric?

Antistatic fabrics play a crucial role in mitigating the risks associated with static electricity in various industries. By providing a controlled path for the dissipation of static charges, they help protect sensitive equipment, enhance safety, and maintain the integrity of electronic components and products.

Called "conductive silk," this fabric is made of special polyester filaments and high quality conductive yarns, and can be used to sew functional garments such as coveralls, suits, jackets, hats, boots, and more. It offers good resistance to static electricity, chemicals, and abrasion, and is designed for Grade 1000 cleanrooms and better.

Conductive fiber fabric also finds application in several industries, such as in electronics, medical, biology, optics, and aerospace industries. It meets ESD standards, with a system resistance of 10e6-10e8Ω. Its purpose is to stop the accumulation of static electricity on garments. It is achieved by either separating layers of conductive fibres, or interweaving them during spinning. The fabric's charge density should average ≤ 7.0μc/m2 after 100 washes and a temperature of 20± 5 ℃, and a humidity of 30~40%. Additionally, the charge accumulation in each piece of clothe should be below 0.6μ c/pc.

Finally, the washability (A-grade ≥ 33.0 h; B-grade ≥ 16.5 h), and non-washability (A-gradeub ≥ 20.0 h; B-grade ≥ 10.0 h) of the fabric should also be taken into account.

| Parameter | Value |

|---|---|

| Static Decay | 0.1s |

| Tear Strength | 20-30N |

| Yarn Count | 100d*100d, 100d*100d |

| Use | Jacket, Shirt, Bag, Blanket, Cap, Curtain, Dress, Garment, Industry, Shoes, Suit |

| Weight | 200-400g/m2 |

| Style | Other, TWILL, Antistatic |

| Width | 58/60 |

| Function | Antistatic |

| Applicable to the Crowd | Women, Men, GIRLS, BOYS |

| Type | 5mm Grid/strip Fabric Or 4mm Grid/strip Fabric |

| Keywords | electrically conductive fabric, electrically conductive fabric, anti-static fabric, anti-static fabric |

Fairtech FR2101 Anti Static ESD Fabrics have been designed to provide the highest level of protection and performance to prevent static electricity from damaging delicate electronics and other sensitive components. The fabric is made of 98% polyester and 2% conductive filament, which ensures excellent flexibility and tear strength of 20-30N. It also features a high density of 188*120 and is certified by CE and ISO. The fabric is available in 100-130meter/roll and is priced at USD1.1/Meter with a minimum order quantity of 100 Meter. Delivery can be expected within 3-5days after payment is received through L/C, D/A, D/P, T/T, Western Union, MoneyGram. Fairtech FR2101 Anti Static ESD Fabric can be supplied up to 10000000meter per Week and is ideal for use in a wide range of industries including electronics, semiconductor, automotive, aerospace, and pharmaceutical. It is the perfect choice for providing reliable protection against static electricity and ensuring safe and efficient operations.

At [Company], we are committed to providing comprehensive technical support and service for our Anti Static ESD Fabrics. Our experienced service team provides a wide range of services including installation, troubleshooting, repair and maintenance. We also provide training to ensure that our customers are well-informed and confident in their use of our products. Our team is available to answer any questions you may have and provide guidance to help you find the best solution for your application.

We also offer a range of testing and certification services to ensure that our products meet the highest standards of quality and performance. Our testing and certification process involves rigorous testing to ensure that our fabrics meet all safety and performance requirements. Our team can also provide assistance in developing custom solutions to meet your specific needs.

We are proud to offer comprehensive technical support and service for our Anti Static ESD Fabrics. For more information, please don't hesitate to contact us.

Q1. What are the disadvantages of ESD?

A1: Electrostatic discharge (ESD) occurs when a non-conducting surface is rubbed against another and the contacted surfaces are then parted. ESD can damage or destroy sensitive electronic components, erase or alter magnetic media, or set off explosions or fires in flammable environments.

Q2.What is ESD protection?

A2: Protection against electrostatic discharges (ESD) is part of EMC Immunity (Electro Magnetic Compatibility) requirements. It is the ability for equipment to properly operate in its electromagnetic environment by limiting the reception of electromagnetic energy that may cause physical damage.

Q3. What is the difference between antistatic and ESD?

A3: Anti-static floors usually have a coating or chemical additive that dissipates static across its surface so that you never build up enough charge to get a shock. ESD is a much more robust solution that delivers more consistent, long-term results because it's actually earthed.

Q4.What are 4 ways to prevent ESD?

A4: Keep electrostatic-sensitive parts in their containers until they arrive at static-protected workstations. Place parts in a static-protected area before removing them from their containers. Avoid touching pins, leads, or circuitry. Always be properly grounded when touching a static-sensitive component or assembly.

Q5.How important is ESD protection?

A5: ESD protection is a vital consideration when working with sensitive electronic components and assemblies. ESD stands for electrostatic discharge and refers to sudden releases of built-up static electricity. This common phenomenon can damage electronic parts if not guarded against.