Shenzhen Topfan Technology Development Co., Ltd. |

|

40MM DC Blower Fan Motor / 1.6 inch DC Cooling Blower Fan / 40 × 40 ×10MM Motor

Applications

Description:

● High speed , Middle speed, Low speed

● Plastic Frame or Die-Cast Aluminum Frame and Plastic impeller

● 5 blades 7 blades or 9 blades

● 5V DC or 12V DC or 24V DC

● Ball bearing or Sleeve bearing or Hydraulic bearing

● Terminal or Lead wire

● Waterproof explosion proof or high proof are can be

satisfied.

A: Specifications:

| Item | Specification/Description |

| Dimension | 40*40*10 MM(L x W x Thickness) |

| Housing | BLACK PBT 94V-0 |

| Fan Blade | BLACK PBT 94V-0 |

| Rated Voltage | DC 12V |

| Operation Voltage | DC 6.0V-13.8V |

| Start-Up Voltage | DC 7 V(Power ON/OFF) |

| Rated Rotate Speed | 8500±10% RPM |

| Rated Current | 0.10A |

| Rated Power | 1.2 W |

| Air Flow | 3.1 CFM |

| Air Pressure | 14.36 mmH2O |

| Noise Level | 35 dB(A) |

| Bearing | Sleeve Bearing |

| Locked protection | Yes |

| Output Signal | RD |

| Soft Start | Yes |

| PWM Control | NO |

| waterproof class | NO |

| Plarity Protection | NO |

| GP Type | Yes |

| Safety Approvals | CE |

| Lead Wire | UL1007 #28AWG L=300±10mm |

| Life Expectancy | 30,000 Hours (At 25℃/Relative Humidity 65%) |

| Net Weight | 18/Gram |

| Packing | 500 PCS/CTN |

B: (Main Materials, Parts Specification):

Bearing | □ (Dual Ball Bearing) | ■ | (Sleeve Bearing) | |||||||

Frame | ■ | PBT of UL94V-0. | □ | Die-cast Aluminum Alloy | ||||||

Impeller | ■ | PBT of UL94V-0. | □ | Steel | ||||||

Bobbin | PBT of UL94V-0. | |||||||||

Lead Wire | ■ | Red(+) | ■ | Black(-) | □ | Blue(PWM) | UL 1571 28# | |||

□ | Yellow(FG) | □ | White(RD) | 2 wires 100±10mm | ||||||

Connector | No | |||||||||

Tube | No | |||||||||

C: Application Notice:

1). SCOPE:

This document defines mechanical&electrical haracteristics of DC Brushless Fan)

2). General Description

2.1 General Specification: Refer to page 2

2.2 Function:

2.2.1 Signal Output Frequency Generator (FG)

RPM= (FG)*30

2.2.2 RD High and low level signal output Protective alarm function

2.2.3 Speed Control Type PWM Control

PWM input frequency around 18KHZ-30KHZ,PWM max input voltage 5.5V

3). Electrical characteristics

3.1 Insulation resistance

Not less than 10M ohm between housing and positive end of lead wire(red) at 500VDC.

3.2 Dielectric strength

No damage should be found at 500 VAC for 60 seconds,measured with 1mA tirp current between housing

and positive end of lead wire.

3.3 Insulated Type UL: Class A(105℃)

4). Electrical &Mechanical Test

4.1 Rotation

Clockwise Rotation View From Label Side

4.2 The performance including air flow and air pressure measured in Double Chamber is measured according to AMCA210-85 standard

4.3 Locked Rotor Protection

4.1.1 To low current fan or auto-start fan, No damage shall be found after 72 hours at condition of rotor locked,The fan automatic rerun as soon as constraint has been released

4.1.2 To high current fan or no auto-start fan ,It can’t be locked or the fan will overheat and be damaged

5). RoHS Compliance

Hazardous substances contents in our product is in compliance with RoHS 2002/95/EC requirement

6). Life Expectancy

Average life is about 50000 hours while fan is operating at rated voltage in room temperature

25℃and relative humidity 65% environment, Please refer to page 2;

7). Environmental

7.1 OPERATING TEMPERATURE RANGE -10 to +70 deg.C

7.2 STORAGE TEMPERATURE RANGE -40 to +75 deg.C

7.3 OPERATING HUMIDITY 5 TO 90% RH

7.4 STORAGE HUMIDITY 5 TO 95% RH

8). Protection

8.1 Polarity Protection

Be capable of withstanding 10 minutes will not cause damage if reverse connection for positive and negative leads;

8.2 Locked Rotor Protection

The current will shut down or remain a little range to protect motor from fire in 72 hours when locking rotor at operation voltage range and at operation temperature;

9). Notes

9.1 JWE Corp.will not assume responsibility for the performance of the products if the application condition falls beyond the parameters stated forth in this specification.

9.2 The correct polarity, Positive(+) and Negative(-), has to be clearly identified before connecting

this product to the power supply. Please do not connect this product to the power supply with

reverse polarity.

9.3 Please do not store the fan in the environment of high humidity. Please avoid storage of the fan over 6 months . For long term storage, please connect power to the fan shortly every 6 months even through the fan is stored in room temperature.

9.4 When handling or operating this product, please do not apply pressure to or drop this product, or handle this product by its lead wires.

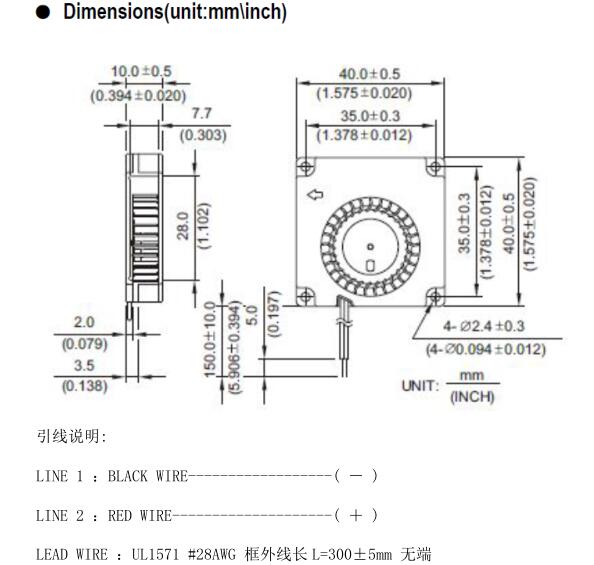

Dimensions (Unit:mm)