Guangzhou Teikuko Auto Parts Co.,ltd |

|

Verified Suppliers

|

|

EK100 EK200 K13D Cylinder Liner/Sleeve Excavator Engine 11467-1910 11467-1960

SPECIFIION:

| HINO EK100 EK200 EK130T Appliion: TRUCK No. CyI: 6 Diameter: 137.0MM | |||||

| Piston | OEM No. | Compress Height | Total Length | Pin Size | Feature |

| 90.5 | 145.4 | 50x110 | w/al-fin | ||

| Piston Ring | OEM No. | Size1 | Size2 | ||

| 13011-1010 | 3.3DK+3.5+3.5+6.0 | ||||

| Cylinder Liner | OEM No. | Size | Flange | ||

| 11467-1910 | 137.0x153.0x267.0 | 164.0*12.1+0.8 | |||

| Engine Bearing | OEM No. | Main Bearing | Con Rod Bearing | Bush | |

| 11701-1013 | 13201-1012 | 13272-1010 | |||

| Engine Valve (IN) | OEM No. | Head Diameter | Stem Diameter | Total Length | |

| 13711-1420 | 57.0 | 12.0 | 170.0 | ||

| Engine Valve (EX) | OEM No. | Head Diameter | Stem Diameter | Total Length | |

| 13715-1013 | 53.0 | 12.0 | 170.0 | ||

| Valve Seat | OEM No. | ||||

| Valve Guide/Sub Parts | OEM No. | ||||

SURFACE TREATMENT:

| Principal Surface Treatment Processes | |

| DCP | Phosphating and chromium plating on jacket only |

| DC | Water jacket only is chromium plated |

| DPF | Water jacket only is phosphated |

| BCP | Phosphating and inner diameter is chromium |

| FF | Inner diameter is Full-Finished for dry type liner |

| SF | Inner diameter is Semi-Finished for dry type liner |

| IN WHITE | Without any special surface treatment |

| DCU | Outer diameter is cooper plated for dry type liner |

| PF | Phosphated all over |

| Air compression liner | |

| Chromed liner | |

| Liner | |

WET CYLINDER LINER:

The loion bores and particularly the running surfaces in the cylinder block must be cleaned carefully and they must

be undamaged. Corroded surfaces must be reworked (used flange liners and outer diameter oversize liners). As this is

done, make sure that the liners moves in easily and that they take up the correct position (the projecting length of the

liner must be in accordance with the regulations of the engine manufacture). After the liner has been installed with the

seat rings that belong to it.

(use slip agent), the cylinder diameter is to be checked particularly in the region of seal rings so as to determine whether

any deformation has been caused by pinched sealing rings. Using the wrong sealing rings (wrong diameter/ wrong

materials) can a narrowing of the cylinder which can lead to engine damage.The cooling system should be pressure

tested after the liners have been installed so as to determine whether there is any leakage before the engine is started.

SEMI-FINISH CYLINDER LINER:

The surface which supports the flange must be vertical to the loion bore and it must be sufficiently and evenly beveled. If the

liner flange is unevenly supported it can tear off. After the installation of the liner, which is only semi-finished in its inside

diameter, this cylinder boring is finely bored and then finished by

honing until it has the specified dimensions or, in the box of

finely bored liner.It is only finished by honing (tolerance

accordingly to DIN ISO H5). The surface of the liner must be flush

to the

sealing surface of the cylinder block, if necessary,the block surface and the liner must be finished by surface grinding.

FINISH CYLINDER LINER:

Before the liner is installed, the loion bore in the cylinder block must be cleaned carefully and must be checked to

ensure the accuracy of the dimensions and to determine whether any distortion has occurred. Out of center or damaged

bores can be reworked for the installation of oversize liners. It is important for this that the loing bore is cylindrical, as

this is what determines the geometrical shape of the inside of the pressed in, thin walled liner.

AIR COOLING CYLINDER LINER:

5)In accordance with the instructions from the engine manufacture, cast iron cylinders or light alloy cylinders are used.

Light alloy cylinders are separated into several groups due to the small installation clearance in the standard cylinder dimensions.

DESTRIPTION:

| HINO | DM100 | 11467-1440 | 6 | 90 | 199 |

| HINO | DQ100 | 11467-1480 | 6 | 92 | 199 |

| HINO | EC100 | 11467-1130 | 6 | 97 | 206 |

| HINO | DS70/DS90 | 11467-1280 | 6 | 105 | 261 |

| HINO | DS50 DS60/DS80 | 11467-1550 | 6 | 110 | 266 |

| HINO | EL100 | 11467-1240 | 6 | 116 | 222.5 |

| HINO | DK10(NEW) | 11467-1380 | 6 | 120 | 292 |

| HINO | EB300 EB400 | 11467-1180 | 6 | 120 | 288 |

| HINO | ED100 ER200 | 11467-1370 | 6 | 128 | 291 |

| HINO | EF300/EF350 | 11467-1071 | 8 | 132 | 248 |

| HINO | EF500 | 11467-1101 | 8 | 135 | 248 |

| HINO | EF550 | 11467-1690 | 8 | 135 | 248 |

| HINO | K13C | 11467-2090 | 6 | 135 | 267 |

| HINO | EK100 EK200/K13D | 11467-1910 11467-1960 | 6 | 137 | 267 |

| HINO | EF700 EF750/F17D | 11467-1091 11467-1900 | 8 | 137 | 248 |

| HINO | F17C/F17E | 11467-1702 | 8 | 139 | 248 |

| HINO | V22C | 11467-2130 | 10 | 139 | 248 |

CYLINDER LINER PACKING:

1. Neutral packing

2. JTP packing

3. YJL packing

4.Customized packing

5. Your brand packing

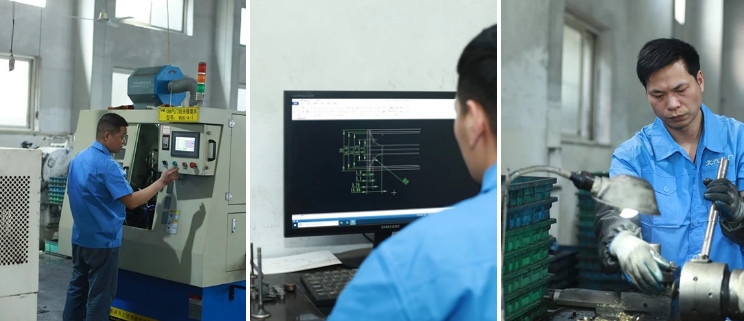

OUR CYLINDER LINER FACTORY:

We are a professional R&D and production manufacturer in marine engine parts, manifold, piston and cylinder liners. Our products have various industrial appliions in marine engine, automotive, engineering vehicle, agricultural vehicle and locomotive. We can make most cylinder kits according to customers’ special need.

We have been certified to ISO9001:2008;ISO/TS16949:2009,

continuously invests in process and quality improvement. We are

always committed to improve all aspects of our business, from

people, equipment to the entire production programs. Our willing is

to always provide the best quality piston and cylinder liner for

your high-performance engines.

JTP/YJL MECHANICAL PARTS ADVANTAGES:

1.Factory Price,Factory Supply,Factory Genuine Quality

2.All earthmoving equipment,excavator engine parts supply

3.All quality level choosen,All price level choosen ,All brand

packing choosen

4.Low MOQ,Sample delivery.

5.24 hours online feedback,email replay within 5hours.solve any

problem might occurs.

FAQ:

1.Do you have other engine model?

Yes, we have a lot of engine model like 6D22, 8DC9, NT855, etc.

2.Are you trading company or manufacturer?

We are an engine parts trading company, a distributor of some

manufacturers.

3.How long is your delivery time?

About 120 days. By DHL or TNT about 14 days after payment.

4.Do you provide samples? Is it free or extra?

Sorry we don't provide samples. Our minimum amount is ONE piece.

5.How to buy with you?

You can use "Chat now!" or email to us.

6.What kind of parts you supply?

We supply PISTON, PISTON RING, LINER, GASKET KIT, BEARING, etc.

7.If out of stock, how much time do you need to transfer from

factory?

Piston ring is made in Japan need 5-6 month to transfer from Japan

if out of stock.

8.What information should I let you know if I want to get a

quotation?

To get an accurate quotation, please let us know the exact part name, quantity, quality level and trade terms like EXW, FOB and so on. More details provided will help.

CYLINDER LINER PICTURE AS BELOW: