Ningbo haijiang machinery manufacturing co.,Ltd |

|

Verified Suppliers

|

|

Generally, precision injection moulding machine has two indexes: the repeated error of product size and the repeated weight error of product.

The former is difficult to compare because of the size and thickness of the product, while the latter represents the comprehensive level of the injection machine manufacturer. The weight repetition error of ordinary injection moulding machine is about 1%, the better machine can reach O.8%, the precision machine is less than 0.5%, the ultra-precision machine is less than 0.3%, and the international highest level is less than O.15%.

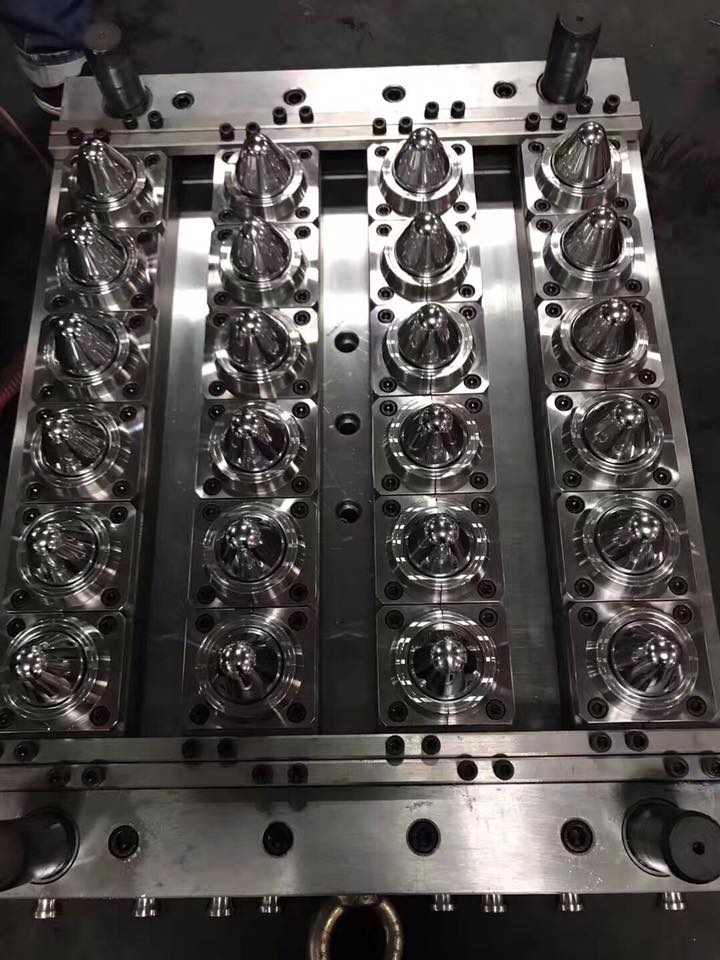

Precision injection machines require the dimensional accuracy of products to be within 0.01-0.001 mm, and many precision injection moulding machines require high injection pressure and injection speed;

the clamping system is required to have sufficient rigidity and clamping precision; the pressure, flow rate, temperature, measurement and other parameters are required to be controlled accurately to the corresponding accuracy; multi-stage or stepless injection is used to ensure the moulding process;

The reproduction conditions and the repetition accuracy of the products are also discussed. The repetitive precision of injection moulding weight is stable, which includes three aspects: repetitive precision of plasticizing quantity, repetitive precision of injection quantity and temperature control performance of moulds.

There are many factors affecting these accuracy, the most important is the accuracy of the whole machine manufacturing and assembly, as well as the configuration of screw, electrical appliances, hydraulic and other parts of the injection machine, and the quality of the mold.