Shanghai Marine Diesel Engine Research Institute |

|

Refinery SMO Titanium Welded Plate Heat Exchanger Sheet Bundle Mounted

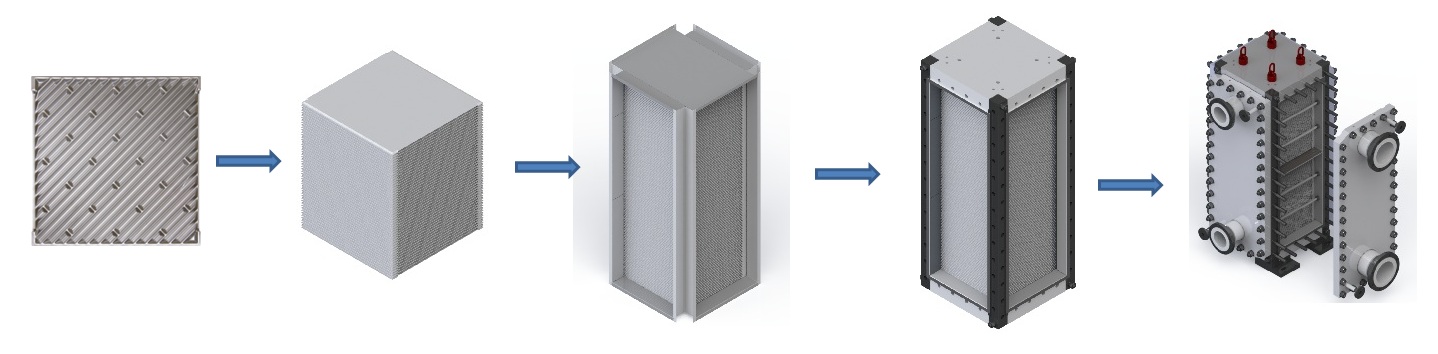

Block-type & Fully-welded Plate Heat Exchanger is a new product in the compact heat exchanger family.

The plate bundle fully welded with plate sheets is mounted into a frame of 4 bolted side panels with a top plate and a base plate sustaining pressure. The side panels are provided with nozzles with fluid inlet and outlet.

Due to the bolt-connected structure, the plates can be easily demounted for easy cleaning and maintenance of the plate bundle.

The plate sheets are welded to each other without any gasket used, so it can be applied for high temperature & pressure applications.

The corrugated profile of plate sheet causes heavy turbulence of the fluid, so the heat transfer coefficient is 2-4 times of conventional tube & shell heat exchanger. Under the same working condition, the required area for heat transfer is only 25-30% of conventional tube & shell heat exchanger.

Work Principle / Flow

Thin metal sheets are pressed to produce corrugated plates and then a stack of such corrugated plates are welded one another and thus form the block type & fully welded plate heat exchanger. Neighboring sheets establish narrow and tortuous channels in between and allow the working fluid to flow through. The cold fluid and hot fluid flow through its own channels in order. The cold and hot channels are separated by the sheet naturally, where heat exchange takes place.

Attributable to the structure & working principle, this type of PHE is featured by compact structure, small footprint, high heat transfer efficiency, flexible operation, wide application, low heat loss, easy installation & cleaning, etc.

Specification

| Application | Heat exchange |

| Name | Block-type & Fully-welded Plate Heat Exchanger |

| Model | QYB30, QYB40, QYB50, QYB75 |

| Material | 316L, SMO, Ti, 2205 |

| Code & standard | NB/T47007, GB150 |

| Design pressure | F.V. – 4Mpa |

| Design temperature | -200 - 400℃ |

| Main measuring point | Temperature and pressure at fluid inlet / outlet |

| Seal | Flange |

| Service life for key equipment | 15 years |

| Warranty | 12 months |

| Scope of works/service | Design, manufacture, supply, installation supervision, etc. |

Advantage

Reference

| No. | User | Project | Equipment | Specification | Qty. |

| 1 | Kingboard Chemical Holdings Ltd. | 100,000t/y catalytic cracker | Heavy oil fractionating tower overhead cooler | QYB75 Design pressure: 0.7MPa Design temp.: 200℃ Plate material: 316L | 1 |

| Heavy oil fractionating tower overhead oil gas – hot water heat exchanger | QYB75 Design pressure: 0.7MPa Design temp.: 200℃ Plate material: 316L | 1 | |||

| Light oil fractionating tower overhead oil gas – hot water heat exchanger | QYB75 Design pressure: 0.7MPa Design temp.: 200℃ Plate material: 316L | 1 | |||

| Light oil fractionating tower overhead cooler | QYB75 Design pressure: 0.7MPa Design temp.: 200℃ Plate material: 316L | 1 | |||

| 2 | Nanjing Fubangte Oriental Chemicals Co. Ltd. | Plate heat exchanger upgrading project | Predistillation heat exchanger | QYB50 Design pressure: 0.9MPa Design temp.: 220℃ Plate material: 316L | 1 |

| 3 | Xinao Energy Holdings Ltd. | Nanjing supercritical hazardous waste treatment project | Condenser | QYB50-H-250 Design pressure: 0.4MPa Design temp.: 160℃ Plate material: Ti | 1 |

| Preheater | QYB30-V-60 Design pressure: 0.5MPa Design temp.: 160℃ Plate material: Ti | 1 | |||

| 4 | Shandong Yuhuang (Group) Chemical Co. Ltd. | 50,000t/y MMA project | T240 feed preheater | QYB75-V-400 Design pressure: 1.0MPa Design temp.: 110℃ Plate material: 316L | 2 |

| 5 | Wanhua Chemical Co. Ltd. | Polycarbonate project | Primary/ secondary water cooler | QYB30-V-100 Design pressure: 0.8MPa Design temp.: 125℃ Plate material: 316L | 5 |

| Primary MC wastewater heat exchanger | QYB50-V-200 Design pressure: 0.8MPa Design temp.: 90℃ Plate material: Ti | 2 | |||

| Secondary MC wastewater heat exchanger | QYB50-V-200 Design pressure: 0.8MPa Design temp.: 120℃ Plate material: Ti | 2 | |||

| 6 | SinoPec Luoyang Company | 15GX69 revamp project | Naphtha – crude oil heat exchanger | QYB75-V-300 Design pressure:2.35MPa Design temp.: 150℃ Plate material: Ti | 1 |

| SinoPec Zhenghai Refining & Chemicals Co. Ltd. | CDU heat exchanger replacement | Naphtha – crude oil heat exchanger | QYB75-V-350 Design pressure:2.5MPa Design temp.: 250℃ Plate material: Ti | 2 | |

| SinoPec Jiujiang Company | Oil quality upgrading revamp project | Crude oil – topping gas heat exchanger | QYB75-V-352 Design pressure: 1.5/3.3MPa Design temp.: 200℃ Plate material: Ti | 2 | |

| Crude oil – naphtha heat exchanger | QYB75-V-252 Design pressure:1.5/3.3MPa Design temp.: 200 Plate material: Ti | 2 | |||

| Crude- 3rd side of vacuum heat exchanger | QYB75-V-352 Design pressure: 3.0/3.5MPa Design temp.: 300℃ Plate material: 316L | 2 | |||

| Crude- 3rd side of vacuum heat exchanger | QYB75-V-502 Design pressure: 3.0/3.5MPa Design temp.: 350℃ Plate material: 254SMO | 2 | |||

| Naphtha – hot water heat exchanger | QYB75-V-152 Design pressure: 1.5/1.5MPa Design temp.: 200℃ Plate material: Ti | 2 | |||

| 7 | National Iranian Oil Company | Crude Oil Unit | Stabilized oil/crude oil | QYB75-V-500 Design pressure: 2.1MPa Design temp.: 150℃ Plate material: Ti | 1 |

| 8 | CNPC Sichuang company | CDU fully-welded heat exchanger revamp project | Crude oil – naphtha heat exchanger | QYB75-H-250 Design pressure: 1.6MPa Design temp.: 200℃ Plate material: Ti | 5 |

| CNPC Huhehot Company | CDU heat exchanger upgrading project | Naphtha – crude oil heat exchanger | QYB75-V-500 Design pressure: 2.5MPa Design temp.: 200℃ Plate material: Ti | 1 |