Shanghai Marine Diesel Engine Research Institute |

|

Plate Shell Heat Exchangers For Chemical Industries , Shell And

Tube Heat Exchanger

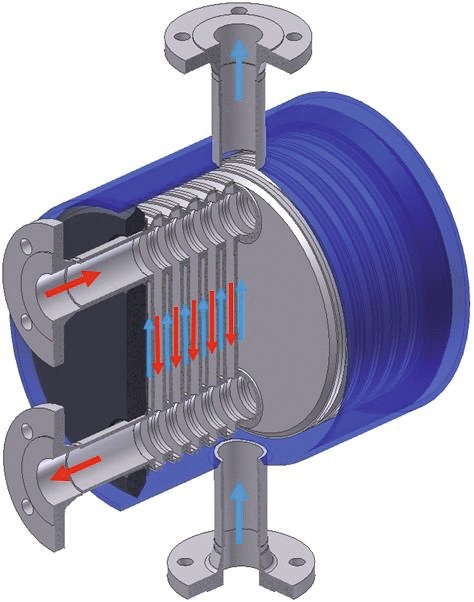

Plate & Shell Heat Exchanger integrates the advantages of plate heat exchanger and tube &

shell heat exchanger as a whole. Owing to such advantages as high

efficient heat transfer, close approach temperature, high pressure

& heat resistance, compact structure and light weight and etc.,

it has been widely applied in power, petrochemical, steel, food and

pharmaceutical industries and etc. The plate & shell heat

exchanger developed by SMDERI is constructed with corrugated sheets

similar with plate type heat exchanger. All round sheets are welded

to each other into a lamella bundle and then mounted into a shell.

There is no gasket between sheets so that it is suitable for high

temperature & pressure applications where conventional plate

frame heat exchangers can’t be used.

Work Principle / Flow Process

Advantages

Reference

| No. | User | Project | Equipment | Specification | Qty. |

| 1 | Kingboard Chemical Holdings Ltd. | 200,000t/y waste animal & vegetable oils to hydrogenated biodiesel project | Heavy biodiesel cooler | QYS50-F-HH-40 | 1 |

| Cold high grade oil - refined oil heat exchanger | QYS80-DF-HH-140 | 2 | |||

| Cycle oil steam generator | QYS150-F-HH-300 | 1 | |||

| Raw oil – refined oil heat exchanger | QYS80-DF-HH-152 | 2 | |||

| 2 | Xindi Energy Engineering Technology Co. Ltd. | LNG contingency reserve project | Refrigerant secondary cooler | QYS200 | 1 |

| Coal gasification unit | Quench water heat exchanger | QYS25 | 1 | ||

| Supercritical water heat exchange | Supercritical heat exchanger | QYS80 | 1 | ||

| 3 | Dalian Refrigeration Machine Co. Ltd. | Freon reduction project | Ammonia – CO2 evaporative condenser | QYS100 | 2 |

| 4 | SinoPec Changling Company | 1# waste heat boiler feedwater preheater | Boiler feedwater preheater | QYS80 | 1 |

| SinoPec Maoming Company | Cracker methanator system | Hydrogen – hydrogen heat exchanger | QYS80 | 1 | |

| SinoPec Jiujiang Company | Low grade waste heat power generation | Evaporator | QYS200-HA-600 | 4 | |

| Condenser | QYS200-HA-600 | 4 | |||

| Rectisol system | Lean – rich liquid heat exchanger | QYS200-HA-650 | 3 | ||

| SinoPec Changling Company | Diesel hydrogenation unit ORC system | Evaporator | QYS200 | 2 | |

| Condenser | QYS200 | 3 | |||

| 5 | Wanhua Chemical (Ningbo) Co. Ltd. | Liquid ammonia cooler | QYS80 | 2 | |

| 6 | CNOOC | Wenchang 13-1/2 oilfield propane cooler | Debutanizer return flow condenser | QYS100 | 1 |

| LPG propane cooler | LPG propane cooler | QYS100 | 1 | ||

| 7 | Coolsummer (Iran) | EO/EG | Lean/Rich MEG | QYS100-HH-128/1/1 | 1 |