Shanghai Marine Diesel Engine Research Institute |

|

EPC Service Boiler Feed Water Preheter Consists Of Flue Gas Heat

Exchanger

Water-Heat-Medium technology

The water-heat-medium technology mainly functions to further recover the heat in low temperature

flue gas while make sure that no corrosion is caused at the

equipment so as to maximize the energy saving and minimize the

energy consumption.

Work Principle/Flow

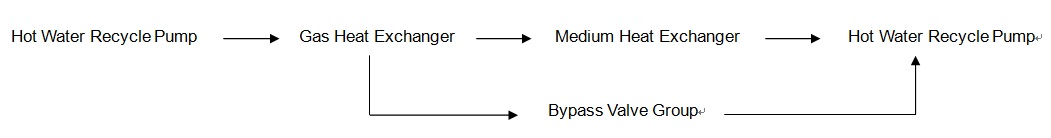

* The water-heat-medium system mainly consists of flue gas heat exchanger, medium heat exchanger

(air preheater, feedwater preheater or other medium preheater), hot

water circulation pump, regulating valve set and etc. The flue gas

heat exchanger is located at the flue duct at the tail of heating

furnace or boiler and the medium heat exchanger is located at the

flow path of the medium to be heated.

* The water-heat-medium system uses a medium pressure deaerated water (2.5~5.0MPa) to maintain

the operating pressure of the system and improve the saturation

temperature of the heat medium water, which is helpful to improve

the heat transfer grade and maximize the waste heat recovery

process. During normal operation, water-heat-medium system itself

does not consume any deaerated water.

* The hot water circulation pump functions to overcome the flow

resistance of water-heat-medium system and continuously transfer

the heat absorbed by the heat medium water in the flue gas heat

exchanger to the medium to be heated. The bypass regulator valve is

to regulate the inlet temperature of heat medium water at the flue

gas heat exchanger inlet and make sure it is above the flue gas dew

point temperature.

Heat medium water flow

Process flow of water-heat-medium system

Structure & Parameter

| Service | Waste heat recovery |

| Equipment | Non-corrosion water-heat-medium preheater technology |

| Specification | Integral modularized structure |

| Components | Flue gas heat exchanger, medium heat exchanger (air preheater, feedwater preheater or other medium preheater), hot water circulation pump, regulator valve |

| Material | Shell: Q235B |

| Fabrication code | Steam boiler safety & technology supervision regulation |

| Flue gas flow | Min.: 5000Nm3/h |

| Inlet flue gas pressure | -5.0-10.0Kpa |

| Inlet flue gas temperature | 200-500℃ |

| Outlet flue gas pressure | -4.0-9.0Kpa |

| Outlet flue gas temperature | 120℃-150℃ |

| Refractory lining | Aluminum silicate fibre felt |

| External wall temperature of equipment | ≤60℃ |

| Utility | 2-Phase power supply: 10Kw |

| Main measuring points | Inlet flue gas temperature |

| Main interlocked alarm | nlet flue gas temperature high |

| Service life of critical equipment | Design service life: 8 years |

| Downtime of spare parts | 3~4 months |

| Warranty period | 12 months since normal operation or 18 months since delivery to site, whichever comes first |

| Scope of work/service | EPC |

| Response to service request | 24hs |

| Application | Oil refining, chemical and coal chemical industries |

Advantage

(1) Flexible and easy arrangement

(2) Wide adaptability to various fuels

(3) Accommodation of load change

(4) Improved operation safety

(5) Common use for multiple adjacent heaters

(6) Extended service life.

Typical Application

No. | Project | Specification | User | Qty. |

|---|---|---|---|---|

1 | 1# & 2# aromatic hydrocarbons hydrogenation cracking heater waste heat recovery system reconstruction | 1# Flue gas flow:11280kg/h | Sinopec Shanghai company | 2 sets |

2 | 1,200,000T/year catalytic plant waste heat recovery | Q179/505-10/79.2-3.82/348 | Shandong Dongming Petrochemical Group | 1 unit |

3 | 2,800,000T/year heavy oil catalytic CO waste heat recovery reconstruction | BQ211/800-42/135-3.82/450 | Sinopec Hainan company | 2 units |

4 | 1,800,000T/year catalytic plant waste heat boiler | BQC235/900-142-3.82/420 | CNPC Fushun company | 1 unit |

5 | 1,800,000T/year catalytic plant waste heat recovery reconstruction | Q310/540-230-3.82/380 | Yanchang Group Yulin Refining & Chemicals Co. Ltd. | 2 units |