Surplus Industrial Technology Limited |

|

Verified Suppliers

|

|

PP Filter

Senior filter solution supplier with multi-industry filtering experience

Material:

PP,Stainless Steel 304/316

Applicable Industries:

Building Material Shops,Manufacturing Plant,Food & Beverage

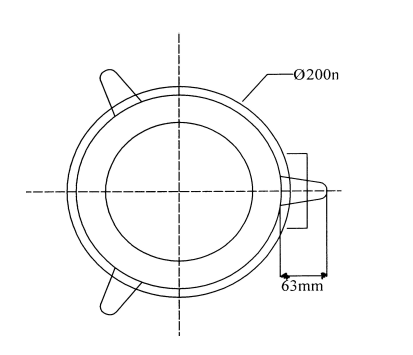

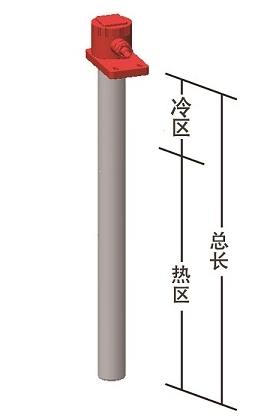

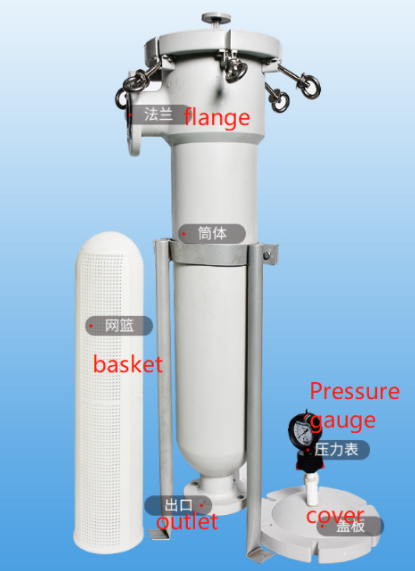

Products detail drawing:

Plastic Bag Filter Housing,Plastic Bag Filter Vessel,Plastic Filter Bag Housing.

FAQ

Q: Where is Surplus located?

A: Our office located in HongKong,Dongguan and Shantou City.Our

factory located in Shenzhen.

Q: Can I buy direct?

A: Yes,you can buy from Surplus Directly.

Q: Do you manufacture your products in house?

A: Most of our products are manufactured in-house at our

factory.Some accessory items are not.

Q: Can I get the riser on my L-shaped aquaculture heater

longer/shorter?

A: Yes.There is no price difference for making a heater with a

middle riser,but there maybe a cost adder for a longer riser.

Q: What Third Party Approvals do your products carry(CE?)

A: Almost all of our products are CE compliant.

Q: How late can you ship?

A: Normally 7 days after comfirmed the order.

PACKING & SHIPPING

In our company,various packing methods are adopted according to

different product features,such as carton boxes,wooden case etc.For

electroplating plant equipment ,we can discuss it together and

choose the most suitable one.

As for shipment,different ways have their own advantage and

disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, expensive

By Express: more flexiable, door to door, expensive

RELATED SPECIES

|  |  |

| PTFE IMMERSION HEATER | PTC IMMERSION HEATER | QUARTZ IMMERSION HEATER |

|  |  |

| METAL HEAT EXCHANGERS | (PFA) HEAT EXCHANGERS | ANODE BASKET |

|  |  |

| PP TANKS | PP BARRELS | PP BAG FILTERS |

OUR FACTORY

|  |  |

| ENGINEER OFFICE | TOOLING DEPARTMENT | MACHING 1 |

|  |  |

| MACHING 2 | MACHING 3 | MACHING 4 |

|  |  |

Company Advantage

For more than ten years, our company has specialized in the

research and development and production of PCB and FPC

electroplating equipment, electric heaters, cold heat exchangers,

and coating on the surface of electroplating equipment. We have

collected advanced technologies and processes at home and abroad

for many years. With the practice and experience in the PCB

industry, the quality, stability and reliability of the products

are among the world's leading positions. Our company has passed

ISO9001: 2008 quality management system certification and CQC: CE

certification, is in line with the world, implements scientific

management, and implements international quality standards.