Shijiazhuang Aier Machinery Co.,Ltd |

|

heavy duty Tailing handling slurry pump of anti-corrison and wear resistant material of high chrome cast iron

Pump Introduction

WZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

Features: high efficiency, energy saving, low vibration, stable operation, low service life, easy maintenance, etc.

Working Conditions

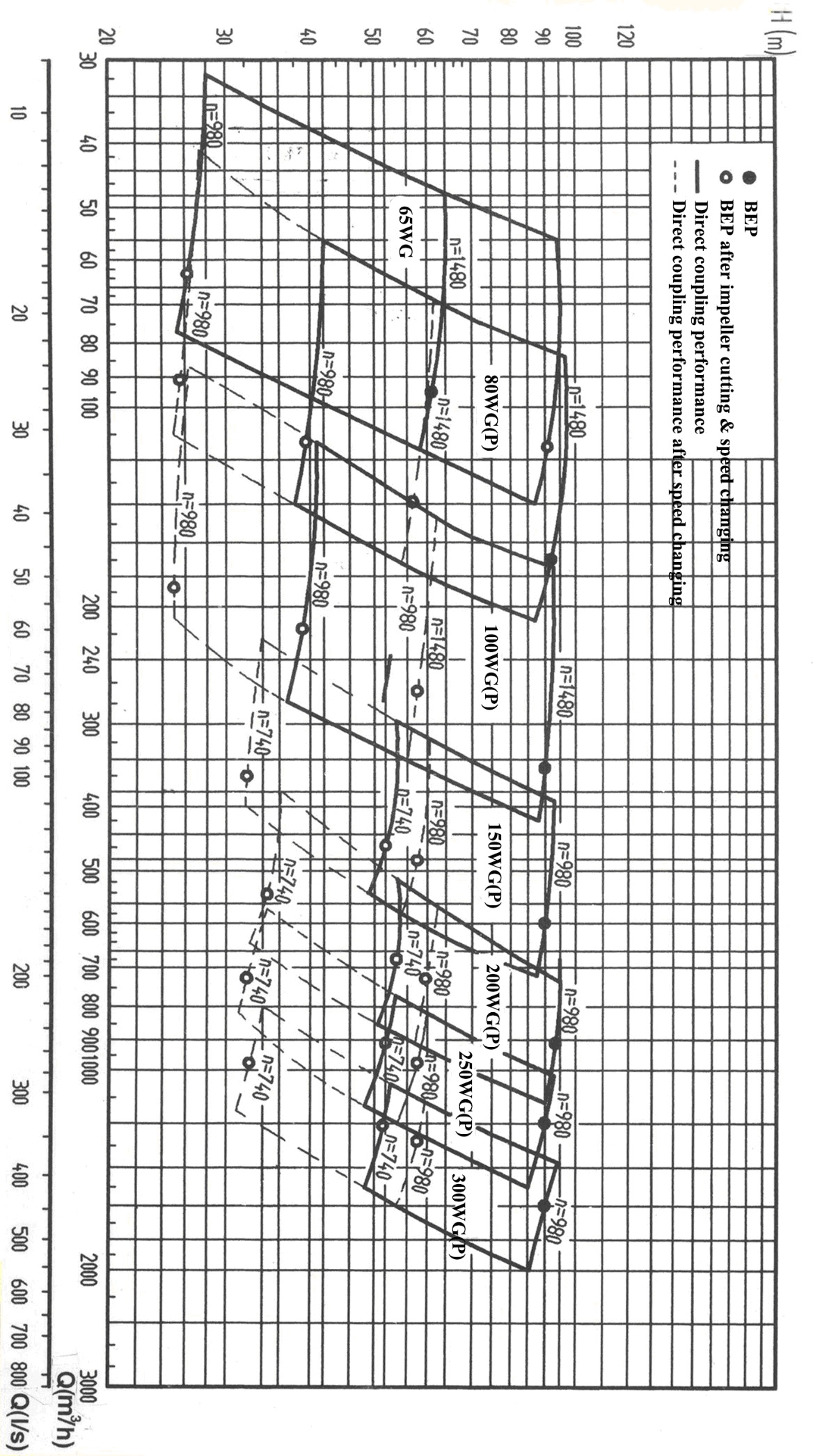

Speed: Direct coupled: 2900/1480/980/730/590 r/min; Other type: as per customer requirement

Medium temperature: commonly ≤ 80 ˚C; specially: 110 ˚C

Weight density of slurry: Grout: ≤ 45%, Mining slurry: ≤ 60%

Capacity: 30 to 2000m3/h

Head: 15-30m

Features

The frame plate for WA series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of hard metal or pressure moulded elastomer liners.

The shaft seals for WA series can be packing seal, centrifugal seal or mechanical seal.

The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

Shaft Seal Type

Packing Seal: high pressure seal water needed. For discharge pressure < suction press single stage installation or multi stage series installation.

Expeller & packing combination: For discharge pressure > suction press single stage installation or multi stage series installation.

Mechanical seal: For users of strict demand of leakage.

Pump Notation

100WZ-42

100: discharge diameter (mm)

WZ: slurry pump

42: impeller diameter (cm)

Material

| Part Name | Material | Specification | HRC | Application | OEM Code |

| Liners & Impeller | Metal | AB27: 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

| AB15: 14%-18% chrome white iron | ≥59 | Used for higher wear condition | A07 | ||

| AB29: 27%-29% chrome white iron | 43 | Used for lower pH condition especially for FGD. It also can be used for low-sour condition and desulfuration installation with pH no less than 4 | A49 | ||

| AB33: 33%-37% chrome white iron | It can transport oxygenated slurry with pH not be less than 1 such as phospor-plaster, nitric acid, vitriol, phosphate etc. | A33 | |||

| Expeller & expeller ring | Metal | B27: 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

| Grey iron | G01 | ||||

| Stuffing Box | Metal | AB27: 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

| Grey iron | G01 | ||||

| Frame/Cover plate, bearing house & base | Metal | Grey iron | G01 | ||

| Ductile iron | D21 | ||||

| Shaft | Metal | Carbon steel | E05 | ||

| Shaft sleeve, lantern ring/resctrictor, neck ring, gland bolt | Stainless steel | 4Cr13 | C21 | ||

| 304 SS | C22 | ||||

| 316 SS | C23 | ||||

| Joint rings & seals | Rubber | Butyl | S21 | ||

| EPDM rubber | S01 | ||||

| Nitrile | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

| Model | Max Mating Power (kw) | Clear Water Performance | Max Solid Though mm | Pump Weight kg | ||||

| Capcity m3/h | Head m | Speed r/min | Highest Effi. % | NPSHr m | ||||

| 40WZ-14 | 7.5 | 4-23 | 9.0-44.5 | 1400-2900 | 52.4 | 2.5 | 11 | 100 |

| 40WZ-19 | 15 | 8-35 | 12.8-57.1 | 1430-2930 | 58.8 | 1.3 | 11 | 160 |

| 50WZ-33 | 18.5 | 12-54 | 7.7-42.5 | 700-1480 | 41.4 | 2.9 | 13 | 450 |

| 50WZ-46 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 13 | 690 |

| 50WZ-50 | 90 | 27-111 | 22.3-110.7 | 700-1480 | 45.1 | 3.0 | 13 | 1050 |

| 65WZ-27 | 11 | 20-72 | 6.0-29.0 | 700-1460 | 62.5 | 1.8 | 19 | 400 |

| 65WZ-30 | 15 | 23-80 | 7.4-35.8 | 700-1460 | 63.5 | 2.0 | 19 | 420 |

| 80WZ-33 | 37 | 43-174 | 8.8-43.3 | 700-1460 | 67.7 | 2.3 | 24 | 580 |

| 80WZ-36 | 45 | 46-190 | 9.6-51.5 | 700-1480 | 68.2 | 2.5 | 24 | 600 |

| 80WZ-39 | 55 | 57-189 | 12.4-60.9 | 700-1480 | 66.0 | 2.5 | 24 | 660 |

| 80WZ-42 | 75 | 61-204 | 14.4-70.6 | 700-1480 | 67.8 | 2.5 | 24 | 680 |

| 80WZ-52 | 160 | 51-242 | 22.1-109.8 | 700-1480 | 56.3 | 2.1 | 21 | 1100 |

| 100WZ-33 | 45 | 56-225 | 8.2-41.6 | 700-1480 | 69.6 | 1.8 | 32 | 700 |

| 100WZ-36 | 55 | 61-245 | 9.7-48.6 | 700-1480 | 72.6 | 2.0 | 32 | 710 |

| 100WZ-39 | 75 | 61-255 | 12.6-61.2 | 700-1480 | 71.0 | 2.4 | 35 | 760 |

| 100WZ-42 | 90 | 66-275 | 14.7-71.0 | 700-1480 | 71.0 | 2.5 | 35 | 780 |

| 100WZ-46 | 132 | 79-311 | 17.3-86.0 | 700-1480 | 68.9 | 2.6 | 34 | 1100 |

| 100WZ-50 | 160 | 85-360 | 20.5-101.6 | 700-1480 | 71.3 | 2.5 | 34 | 1120 |

| 150WZ-42 | 132 | 142-550 | 12.1-64.0 | 700-1480 | 76.4 | 2.2 | 69 | 1550 |

| 150WZ-48 | 75 | 111-442 | 8.7-39.7 | 490-980 | 78.0 | 2.5 | 48 | 1610 |

| 150WZ-50 | 75 | 115-460 | 9.5-43.1 | 490-980 | 78.0 | 2.5 | 48 | 1630 |

| 150WZ-55 | 110 | 124-504 | 12.3-54.2 | 490-980 | 74.5 | 2.3 | 48 | 1660 |

| 150WZ-58 | 132 | 131-532 | 13.7-60.3 | 490-980 | 77.5 | 2.5 | 48 | 1680 |

| 150WZ-60 | 160 | 135-550 | 14.7-64.5 | 490-980 | 77.5 | 2.5 | 48 | 1700 |

| 150WZ-63 | 185 | 146-582 | 16.3-73.7 | 490-980 | 75.0 | 2.5 | 48 | 1900 |

| 150WZ-65 | 200 | 150-600 | 17.4-78.5 | 490-980 | 72.0 | 2.5 | 48 | 1930 |

| 150WZ-70 | 185 | 93-400 | 20.0-91.2 | 490-980 | 62.3 | 2.0 | 37 | 1950

|

| Model | Max Mating Power (kw) | Clear Water Performance | Max Solid Though mm | Pump Weight kg | ||||

| Capcity m3/h | Head m | Speed r/min | Highest Effi. % | NPSHr m | ||||

| 200WZ-58 | 185 | 211-841 | 13.0-59.8 | 490-980 | 81.7 | 2.5 | 62 | 1940 |

| 200WZ-60 | 200 | 218-870 | 13.9-64.0 | 490-980 | 82.7 | 2.5 | 62 | 1970 |

| 200WZ-63 | 250 | 228-921 | 15.4-67.6 | 490-980 | 79.3 | 2.5 | 62 | 2030 |

| 200WZ-65 | 250 | 235-950 | 16.4-72.0 | 490-980 | 80.0 | 2.5 | 62 | 2050 |

| 200WZ-68 | 315 | 199-948 | 18.3-81.5 | 490-980 | 74.6 | 2.8 | 56 | 2130 |

| 200WZ-70 | 315 | 205-976 | 19.4-86.4 | 490-980 | 75.6 | 2.8 | 56 | 2150 |

| 200WZ-73 | 355 | 219-876 | 21.6-98.2 | 490-980 | 74.5 | 3.0 | 56 | 2660 |

| 200WZ-75 | 355 | 225-900 | 22.8-103.0 | 490-980 | 74.5 | 3.0 | 56 | 2700 |

| 200WZ-85 | 560 | 221-907 | 32.0-133.7 | 490-980 | 70.5 | 2.8 | 54 | 3610 |

| 250WZ-60 | 280 | 276-1152 | 13.1-58.4 | 490-980 | 73.9 | 2.8 | 72 | 2800 |

| 250WZ-63 | 315 | 290-1211 | 14.4-64.3 | 490-980 | 76.5 | 3.0 | 72 | 2820 |

| 250WZ-65 | 315 | 299-1249 | 15.4-69.0 | 490-980 | 77.5 | 3.0 | 72 | 2840 |

| 250WZ-68 | 450 | 272-1341 | 17.1-80.9 | 490-980 | 72.5 | 2.7 | 72 | 3120 |

| 250WZ-70 | 450 | 280-1380 | 18.1-85.7 | 490-980 | 74.0 | 2.9 | 72 | 3150 |

| 250WZ-73 | 500 | 292-1441 | 19.7-93.2 | 490-980 | 76.0 | 3.0 | 72 | 3190 |

| 250WZ-75 | 560 | 300-1480 | 20.8-98.4 | 490-980 | 96.0 | 3.0 | 72 | 3230 |

| 250WZ-78 | 630 | 345-1380 | 25.4-109.3 | 490-980 | 70.8 | 3.2 | 76 | 4530 |

| 250WZ-80 | 710 | 354-1415 | 26.7-115.0 | 490-980 | 72.6 | 3.4 | 76 | 4540 |

| 250WZ-83 | 800 | 367-1468 | 28.7-123.8 | 490-980 | 74.6 | 3.5 | 76 | 4550 |

| 250WZ-85 | 800 | 376-1504 | 30.1-129.8 | 490-980 | 75.6 | 3.5 | 76 | 4560 |

| 250WZ-90 | 450 | 378-1374 | 22.3-82.4 | 400-730 | 73.8 | 3.4 | 69 | 4600 |

| 250WZ-96 | 560 | 403-1466 | 25.4-93.7 | 400-730 | 77.8 | 3.5 | 69 | 4650 |

| 300WZ-56 | 250 | 395-1568 | 9.7-46.0 | 490-980 | 81.3 | 3.5 | 96 | 2900 |

| 300WZ-65 | 500 | 589-2166 | 13.8-66.2 | 490-980 | 78.4 | 3.7 | 92 | 2920 |

| 300WZ-70 | 630 | 635-2333 | 16.0-76.8 | 490-980 | 80.4 | 3.9 | 92 | 2940 |

| 300WZ-85 | 450 | 477-1742 | 18.9-69.6 | 400-730 | 78.7 | 3.8 | 85 | 4900 |

| 300WZ-90 | 560 | 505-1844 | 21.2-80.0 | 400-730 | 81.5 | 3.8 | 85 | 4950 |

| 300WZ-95 | 400 | 441-1735 | 13.8-58.8 | 300-590 | 77.8 | 3.0 | 88 | 5010 |

| 300WZ-100 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 80.8 | 3.0 | 88 | 5060 |