HLS Coatings (Shanghai)Co.Ltd |

|

Verified Suppliers

|

|

Solution for the car covers electrophoresis paint.

Product Introduction

| HS-6060LB/HS-2668G Gray Cationic Epoxy Electrocoat for auto is a new generation electrophoretic coating researched and developed by HLS Paint (Shanghai) Co., Ltd. It represents modern technology of cathodic electrophoretic coating that is environment-friendly with high property and low cost. Such coating does not contain heavy metal like lead, tin, cadmium and mercury etc. It is a two-component, water-dispersed resin,meanwhile, it took in features of previous products, and can adapt galvanized steel sheet perfectly, almost can be applied to foundation coating of all metal, such as: cold and hot rolled steel sheet, galvanized steel sheet, aluminum products, zinc-aluminum alloy sheet and stainless steel sheet etc. |

This product features shown below:

| Coating fullness of good, better substrate hiding . |

| Strong anti-corrosion properties, good salt spray resistance workpiece edge. |

| The appearance of the coating is flat, delicate, smooth. |

| Good stability of bath can adaptable for a longer updating cycle. |

| Excellent leveling coating,good bonding force and compatibility with plastic powder. |

Filling tank proportion and method

⑴ Bath preparation

Ratio:

Resin 1000.00-1250.00

Paste 250.00

DI water 1500.00

Total 2750.00

⑵ Ripening conditions

| Sample quantity | 3000~4000g |

| Container | 4L (Diameter 16cm) |

| Tank temperature | 28-30 ℃ |

| Time | 24~48Hr |

| Mixed conditions | impeller diameter 8cm (speed 200rpm) |

(3) Coating conditions

| Experimental panel | phosphated cold-rolled steel plate |

| Tank temperature | 28-35℃ |

| Pole ratio | A/C = 1/2 ~ 1/4 |

| Distance of electrodes | 15cm |

| ED time | For full immersing 1-3 minutes ( 20 seconds soft start) |

| Baking conditions | (175-185)℃×(20-30)min (Keeping temperature of parts coated) |

Product film performance

| Project | Indicator | Test standard | |

| Appearance | Normal / abnormal | Normal | Ocular estimate |

| Hardness | ≥ | 2H | GB/T 6739 |

| Cup drawing | mm ,≥ | 6 | GB/T 9753 |

| Adhesion | Level | 0 | GB/T 9286 |

| Flexibility | mm | 1 | GB/T 1731 |

| Impact | kg·cm | 50 | GB/T 1732 |

| Gloss | 60 | 50-80 | GB/T 9754 |

| Water resistance | h,(23±2)℃,≥ | 240 | GB/T 1733 |

| Acid resistance | h,(50g/L H2SO4),≥ | 72 | GB/T 9274 |

| Alkali resistance | h,(50g/L NaOH),≥ | 48 | GB/T 9274 |

| *Salt spray resistance | h,(film thickness ≥ 20μm) ,≥ | 1000 | GB/T 1771 |

* Note: The substrate use the Bonder standard phosphating steel panel, crossed out unidirectional expansion eclipse ≤ 2mm.

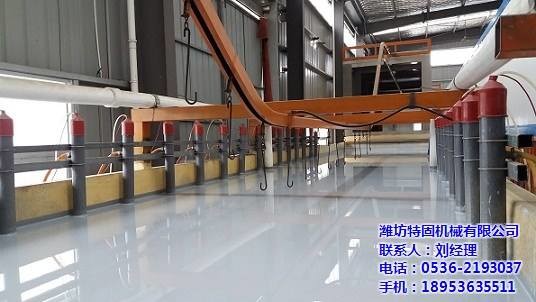

Customer production site