Hangzhou Ecoographix Digital Technology Co., Ltd. |

|

Verified Suppliers

|

|

Cell Phone Carton Paper Box Window Patching Lamination Machine

1. Application

Ecoo TC-1100,TC-1000 automatic window patching machines are special equipment for carton box, color box window lamination for both cardboard and corrugated paper;

The machines are widely used in the film patching to be package with or without the window of the wine box, gift box, tissue paper box, cosmetic box etc. It can also realize the function of the paper gluing, film patching, film cutting and paper collection before folding boxes.

TC1000 is single lane, TC1100 is double lane.

2. Main features:

Option of pre-make ready table is available. Operator can set up the mould outside of the machine .

Equipped with servo feeder, with the choice of option which is piling lifting system and belt lifting system. Adopting advanced world famous brand components in pneumatic parts , electric parts and operation parts.

Apply a linker to connect with the air conveyor , which can directly connect with filling machine .

3.Application and Sample:

4. Technical Specifications:

| Specifications | |||||

| Model | Ecoo-TC1100 | Ecoo-TC1000 | |||

| The producting style | 2-lane operation | 1-lane operation | |||

| Length A of the blank paper | 100mm-900mm | 100mm-420mm | |||

| Width B of the blank paper | 80mm-530mm | 100mm-750mm | |||

| Length window/lining material C | 80mm-760mm | 80mm-280mm | |||

| Width window/lining material C | 30mm-380mm | 30mm-550mm | |||

| Speed of the machine | ≤400pcs/min | ≤200pcs/min | |||

| Carton weight | |||||

| Carton | 180g/m2-600g/m2 | ||||

| Corrugated | ≤1.5mm | ||||

| Film thickness | |||||

| PVC, PE, PS | 0.05mm-0.3mm | ||||

| PET | 0.05mm-0.2mm | ||||

| Outer diameter | ≤500mm | ||||

| Inner diameter | 70mm-80mm | ||||

| The size of the machine | 5600(L)x2000(W)x1500(H)mm | 4800(L)x1600(W)x1500(H)mm | |||

| Main motor power | 4kw | ||||

| Total power | 22kw | ||||

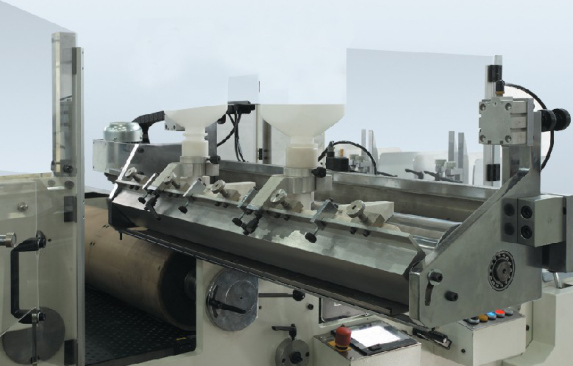

1) Sizing Part(gluing):

The Gluing Section consists of the chrome-plated glue roller, glue

separation plate, side guide and glue mould roller.

The Gluing Section can be easily pulled out ,it's easy to set and

clean.

The glue separation plate is adjustable to control the glue area

and amount.

In case of the machine shutdown, the cylinder will lift the glue

roller and then the machine will be driven by the other separate

motor ,to avoid the leaking of the glue.

Option of pre-make ready table is available, Operator can set up

the mould outside of the machine. It's convenient and time saving.

2) Paper collecting part (delivery stacker)

The belt at the Delivery Section is wide. Operator can adjust the

height of the belt and the finished products are aligned in a

straight line.

Belt speed can also be adjusted to be synchronized with the machine

speed.

3) Feeder part (paper feeding)

The machine is equipped with lower belt feeding system, with the

choice of option which is pilling lifting system and belt lifting

system.

The characteristic of the belt lifting system is high speed thus

increasing capacity.

The characteristic of the pilling lifting system is that the

feeding belt can be run continuously while boxes can go through the

upward/downward movable pilling lifting system. This pilling

lifting system is flexible in capable of feeding different boxes

without scratching the boxes.

The feeding system design is an advance technology. Synchronous

belt feeder is equipped with suction system. At the chain adjusting

section there are four feeding chains.

There is a feeding gate at the feeder which allows you to adjust

upper rail without additional tool. This upper rail is made of flat

steel and is connected to the middle part of the frame.

This system is reliable which ensure the registration of all,

cardboard and chain is accurate.

Even when there is serious jam, the position is precise and you can

use micro-adjustment to adjust.

4) Window patching part

Boxes are delivered from the gluing section to the window patching

section by suction.

Suction is run individually and registered by sensor. When there is

blank sheet, the suction table will go down to avoid sticking of

glue on the belt.

Operator can adjust the volume of suction air according to the size

of the box.

The suction cylinder is made of special material. It is smooth so

that the speed of patching is high and there will be no scratch on

the plastic film.

When the knife cylinder is rolling, it intercrosses with another

fixed knife bar and hence cutting the plastic film like "scissors".

The cutting edge is flat and smooth.

The knife cylinder is with adjustable blowing or suction system to

ensure the plastic film is patched on the window of the box

accurately.