Hangzhou Ecoographix Digital Technology Co., Ltd. |

|

Verified Suppliers

|

|

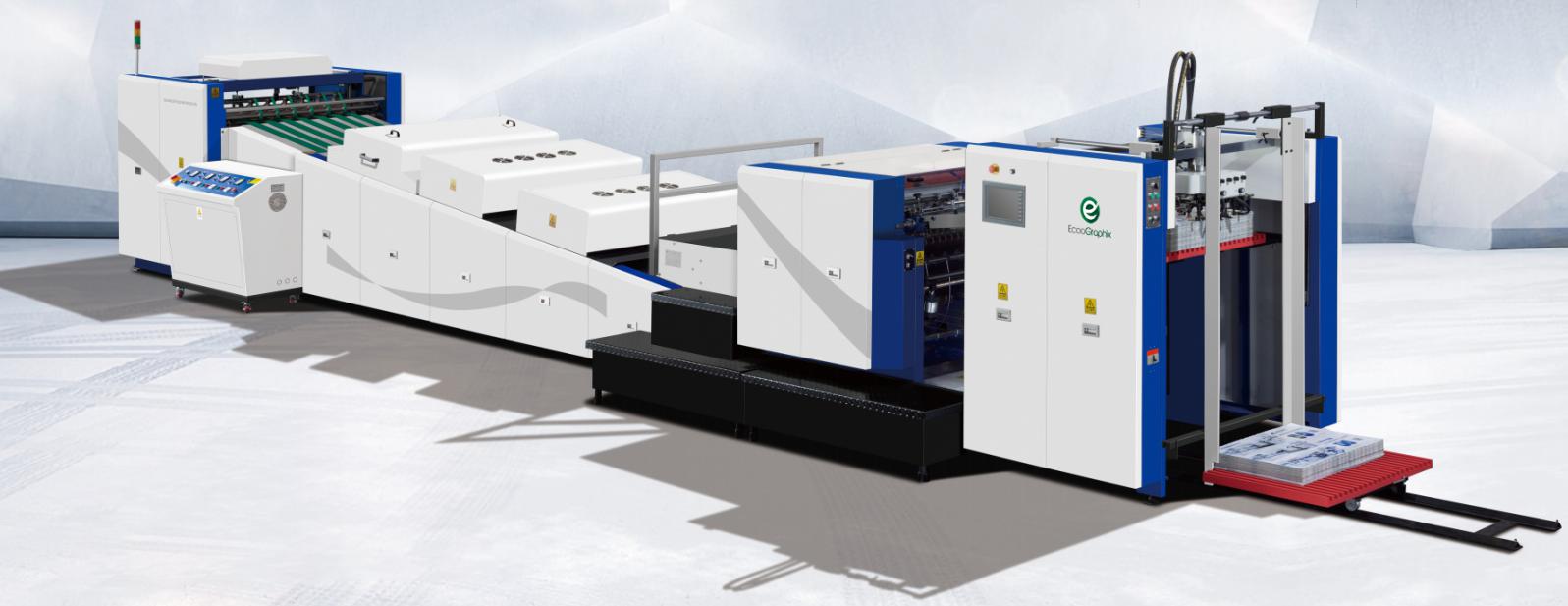

UV Coating Machine model: Ecoo-SD-1060

The High-Speed UV Spot and Overall Coating machine operates at a maximum speed of 9000 sheets per hour using an upper-swaygripper-pass-sheet method. Its UV curing system is equipped with a Teflon conveying belt which ensures higher speed, precise orientation, higher efficiency in UV curing, and lower power consumption. With this machine, you can achieve high-speed production and quality UV coating.

By using a UV coater and a Teflon belt, we can ensure that sheets are treated without causing damage or deformation to the grippers. This prevents any potential maintenance issues and allows for easy upkeep. Plus, we can rest easy knowing that high temperatures from UV light won't cause any harm. All in all, this solution makes for a smoother and more efficient process.

Key Features

Specification

| Model | Ecoo SD-1060 |

| Max. sheet size | 730x1060mm |

| Min. sheet size | 310X406mm |

| Max. coating size | 720x1040mm |

| Sheet thickness | 80-500gsm |

| Coating registration accuracy | ±0.2mm |

| Production speed | 9000sheets/hour |

| Weight | 8T |

| Dimension | 10460x2725x1930mm |

| Power | 44KW |

| Remark: Production speed depends on sheet weight, size, and quality | |

| No. | Description | Specification | Qty | Remark |

| 1 | Rubber Roller | Φ165.3×1118 | 1PC | The ceramic roller is not equipped. |

| 2 | Doctor Blade | 0.15*50*1150 | 1PC | |

| 3 | Floor Pad Plate | 12PCS | ||

| 4 | Chain Link | 5/8" | 1PCS | |

| 5 | Chain Link | 1/2" | 1PCS | |

| 6 | Chain Link | 3/4" | 1PCS | |

| 7 | Tool Box | 1PCS | ||

| 8 | Inner Hexagon Spanner | 1.5,2,2.5,3,4,5,6,8,10 | 1SET | |

| 9 | Spanner | 12" | 1PCS | |

| 10 | Screw Driver | 1PCS | ||

| 11 | Screw Driver | 1PCS | ||

| 12 | Fixing Spanner | 5.5-7,8-10-9-11,12-14,13- 16,14-17,17-19,22-24 | 1SET | |

| 13 | Wooden Piece | 4PCS | ||

| 14 | Grease Port (Straight) | M6x1 | 5PCS | |

| 15 | Grease Pipe Jointer (Straight) | M6x1xΦ6 | 5PCS | |

| 16 | Grease Pipe Jointer ( curve) | M6x1xΦ6 | 5PCS | |

| 17 | Screw | M10x80 | 10PCS | |

| 18 | Operation Manual | 1SET | ||

| 19 | User Manual to Inverter | 1SET | ||

| 20 | Pump Instruction Manual | As per supplier | 1SET |

Producing And Packaging

FAQ

1. What is your warranty?

Normally 1 year.

2. What is the Lead Time?

Usually 45 days, and we will try our best to meet your demands.

3. What about the Installation and after-sales technician support?

Our engineer can help with the installation and provide the

necessary training. The buyer should take the round airplane

tickets and service charge and the local accommodation cost. If you

have any problems or questions, we will be at your disposal 7x24

hours.