Hangzhou Ecoographix Digital Technology Co., Ltd. |

|

Verified Suppliers

|

|

Product Description

Brief Introduction:

The HIS series of UV local glazing machine adopt the Bite-transferring structure and chain track design of offset printing pree. The drying section is a conveyor net structure, adopt the large diameter impression cylinder, so the finished oil film is very flat and even, accurate and bright. It can comprehensive think about both thick and thin papers, and can be used for both full UV and partial UV coating.

| Model | Ecoo HIS-1100 | Ecoo HIS-1280 | Ecoo HIS-1450 |

| Max.sheet size | 1100x1100mm | 1100x1280mm | 1100x1450mm |

| MIN.sheet size | 310X406mm | 350X460mm | 350X460mm |

| Max.coating size | 1090x1090mm | 1090x1270mm | 1090x1440mm |

| Sheet thickness | 80-600gsm | 80-600gsm | 128-600gsm |

| Coating registration accuracy | ±0.2mm | ±0.2mm | ±0.2mm |

| Production speed | 6800sheets/hour | 6500sheets/hour | 6200sheets/hour |

| Weight | 8500kg | 9000kg | 9500kg |

| Dimension | 12010x2779x1818mm | 12230x2960x1844mm | 12230x3100x1844mm |

| Power | 50KW(E) 42KW(W) | 54KW(E) 44KW(W) | 57KW(E) 47KW(W) |

| Remark: Production speed depending on sheet weight, size and quality | |||

1. Feeder

Enlarged feeder with four sucking and six forwarding suckers and

air blowing for spool can feed sheet easily and smoothly.

2. Front Side Lay Gauge

When sheet reaches front lay gauge, left and right pulling lay

gauge can be used. The machine can stop feeding immediately by

sensor without sheet and release pressure to keep bottom roller

under no varnish condition.

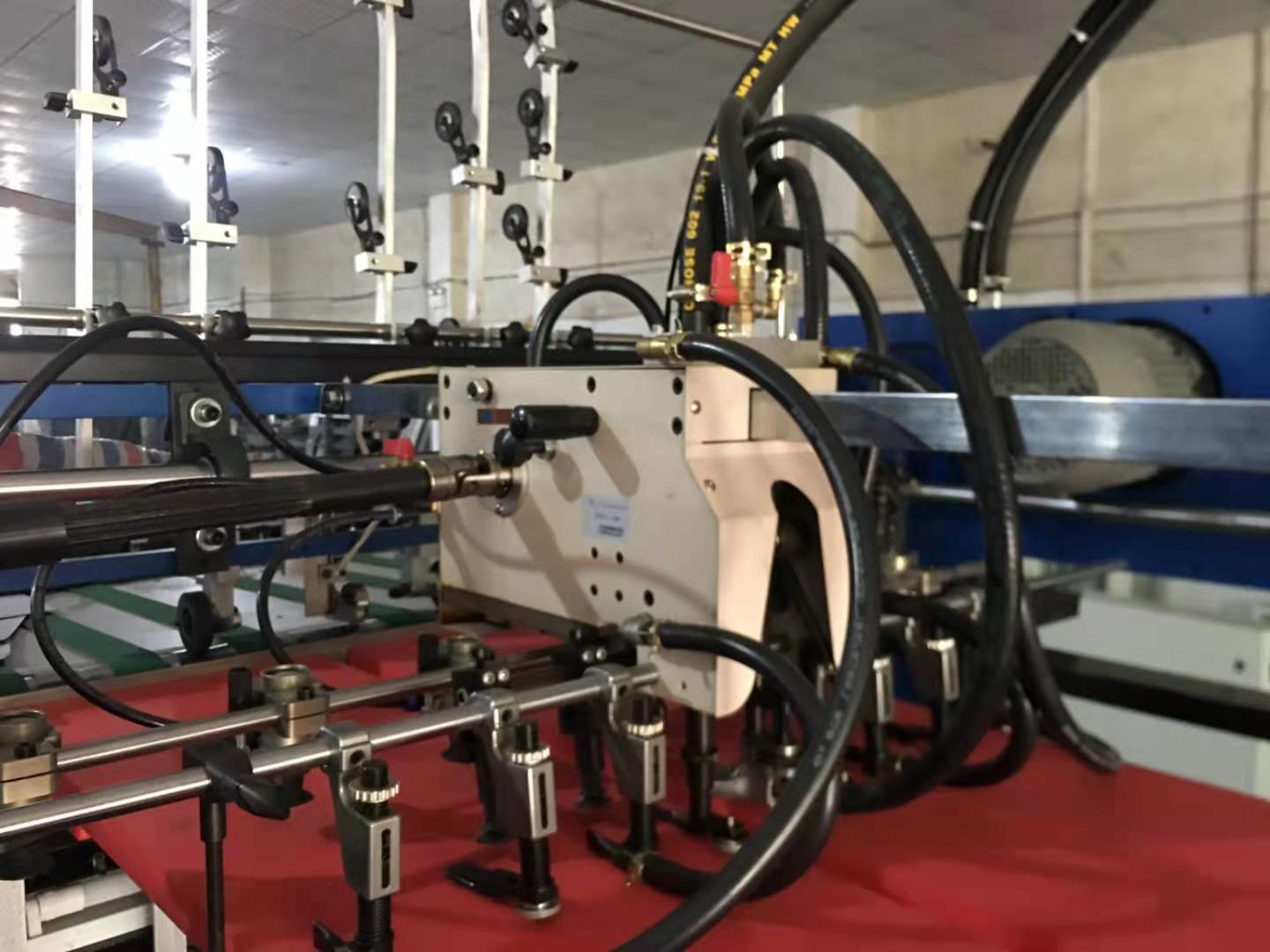

3. Varnish Supply

Steel roller and rubber roller with metering roller reversing and

doctor blade design control by varnish consumption and volume to

meet the demand of products and operate easily. (Varnish

consumption and volume are determined by LPI of ceramic anilox

roller)

4. Transferring Unit

After sheet is transferred from pressure cylinder to gripper, air

volume blowing for paper can support and reverse sheet smoothly,

which can prevent sheet surface from being scratched.

5. Conveying Unit

Upper and lower conveying belt can form thin sheet to be curved for

smoothly delivery.

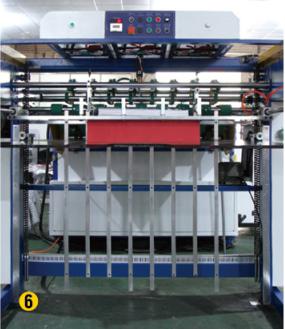

6. Sheet Delivery

Automatic pneumatic patting sheet controlled by photoelectric

detecting sensor make sheet pile fall automatically and collect

sheet neatly. Electronic control can take out sheet sample safely

and quickly for inspecting.

These end users Printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hasle on installations, training and after sales service. We guarantee your satisfaction.