Xinxiang Echo Supplies Co.,Ltd. |

|

Technical Parameters

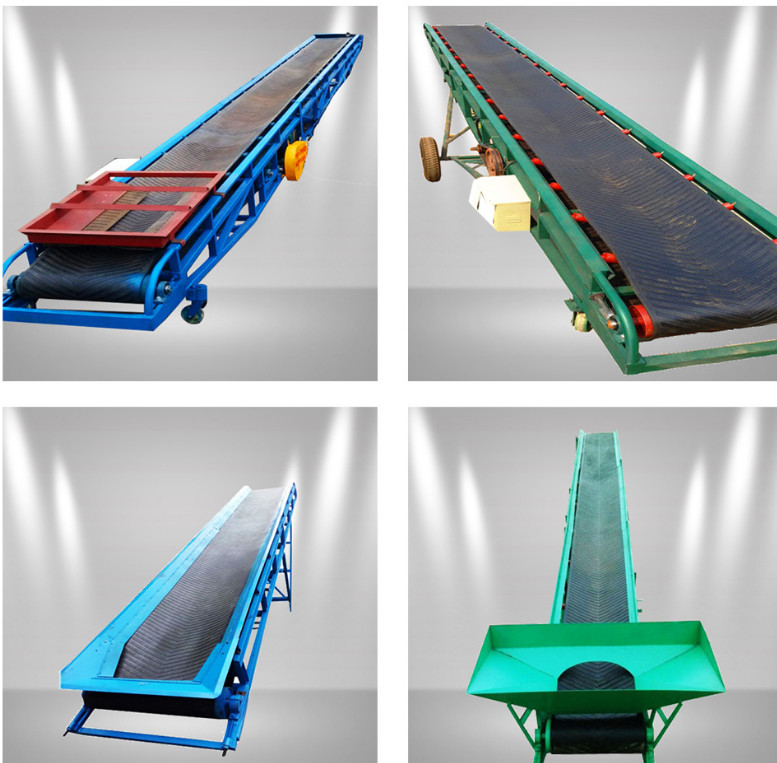

Applicable of the belt conveyor:

A.Can be used for horizontal or tilt transportation and it’s very convenient to use , widely used in various industrial enterprises such as : the underground workings of the mine , mine ground transportation system , open pit and concentrator . According to the transport process requirements , not only can use a single conveyor but also can be composed of multiple components or other equipment to form horizontal or inclined conveyor system to meet needs of different types of layout .

B.Belt conveyor is widely used in metallurgy, coal, transport , water, electricity, chemical and other sectors , because it has a LARGE capacity , simple structure, easy maintenance , low cost , versatility , etc.

C.The belt conveyor also can be used in building materials, electric power , light industry , food , ports , ships and other departments .

Instruction of the used conveyor belt:

The belt conveyor is a kind of friction drive transport material continuously machine . Mainly made of the rack, conveyor belts , idlers , rollers, tensioning device, and gear .

It can be in a certain line , the feed point from the initial to the final discharge point formed a process of delivery of materials . It not only can deliver granular material but also can deliver pieces of goods . Besides this,

it can be combined with the process in the industrial production line and form the rhythmic flow transport line .

Technical data:

Belt Width (mm) | Belt Length(m) / Power(kw) | Belt Speed (m/s) | ||

| 400 | ≤12/1.5 | 12-20/2.2 | 20-25/3 | 0.8-2 |

| 500 | ≤12/3 | 12-20/4 | 20-30/5.5 | 0.8-2 |

| 650 | ≤12/4 | 12-20/5.5 | 20-30/7.5 | 0.8-2 |

| 800 | ≤10/4 | 10-15/5.5 | 15-25/7.5 | 1.0-2 |

| 1000 | ≤10/5.5 | 10-20/7.5 | 20-25/11 | 1.0-2 |

| 1200 | ≤10/7.5 | 10-20/11 | 20-25/15 | 1.0-2 |

Note: The technical parameters above are just for your reference. If there is any change, all parameters and overall dimension are subject to operating instructions. Any questions please feel free to contact us.

Opearting principle:

Belt conveyor mainly composed by two endpoints drum and closed belt . Driven conveyor belt rotating drum called the drive roller ( rotate roller ) ; another change the direction of

movement of the conveyor belt rollers is called bend pulley only . The drive rollers by a motor through a speed reducer driven conveyor belt to rely on the friction drag between the drive

rollers and the conveyor belt . The drive rollers ships are mounted at the discharge end , to increase the traction, and is conducive to drag . Material from the feed end of the feeding ,

falls rotating conveyor belt , relying on the discharge end of conveyor belt friction driven transport bag unloading .

Production details

1 SET/ POLYWOOD CASE

We mainly export Vibrating machine, Lifting machine,

mainly in

powder, starch, flour, rice flour, carbon powder, graphite powder,

manganese powder, lithium carbonate Field.

1. We have very more experience in

export business.

2. All of our products comply with international quality standards.

3.We can do customer’s design and requirement

4. We mainly export to Europe , Americal , South Americal, Africa, the Middle East. Australia, New Zealand etc.