Botou Xinghe Roll Forming Machinery Co., Ltd. |

Specifications

XH-850/900 Double Layer Roll Forming Machinery

size:6.5*1..3*1.5m

weight:3.5t

control system:automatic PLC control system

850-900 Double Layer Roll Forming Machine

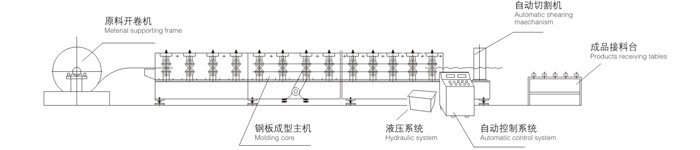

1.Producing Process Show: |

2.Equipment Technical Pamameter: |

Main Forming Machine Technical Pamameter:

machine size | 6500mm*1300mm*1500mm |

Feeding width | 1000mm |

Equipment weight | 3.5T |

Material of shaft | 45#steel adjustable treatment |

Out diameter of shaft | φ70mm |

Material of roller | Cr12, quenched treatment HRC58-60°C |

Number of forming rollers | Down for 850: 9 rows Up for 900:9 rows |

Main frame | 300 H steel |

Thickness of medium plate | 16mm |

Transportation system | Chain transportation |

Thickness of chain | 0.6 inch |

Main motor power | 3 KW |

Bearing | 6213 |

Gear box | 150*150 |

Forming speed | 8-12m/min |

Rolling thickness | 0.3-0.8mm |

3.Equipment Show: |

Packaging & Shipping

1.)we can send our engineer to your site and do the training for your men. you just only bear the cost for our engineer's air ticket,visa,accormadation,food and transpotaion in your country

2.)You can send your men to our factory. we will teach them how to operate the machine without training charges

3. )Actually theres another cheap and easy way to choose. Every machine leave our factory with one book of operation manual. You can read through the manaul first ,and get familiar with the machine. Then we can get a video call,and teach you on-line how to operate the machine.

4.)Apart from above training course,we also provide 1 year warranty for all the easily broken part of the machine for free and whole-life technical service support !

FAQ

A QU: Does one machine can only produce one style panel profile?

AS: Not exactly.For wider and double layer making machine.

It can produce more than 6 kinds of panels.

B QU: How many panels does common machine produce?

AS: Maybe more than two.It depends on feeding width.

C QU: I need the machine to roll form 914mm width sheet and 1219 mm width sheet , ok?

AS: Of course,OK.It is common feeding width. Many kinds of roll forming machine designs available.

D QU: Is your machine suitable for thickness of 0.25mm, 0.28mm and 0.30mm and 0.36mm of sheet thickness?

AS: Yes.Common thickness is 0.3-0.8mm.But it can roll 0.25mm also.

E QU:What is effective width and cover width?

AS:Effective width=Cover with

It means the max distance between two waves of finishing panel sheet.

F QU: What is the largest width of metal sheet I can feed through the machine?

AS: Max feeding width depend on panel profiles.It may be 1500mm or even large.

G QU: So,can you tailor make the machine? it should be common and the profile is a common one

AS:Yes,It is very common.I can give you quotation and advice now!