SINO GROUP |

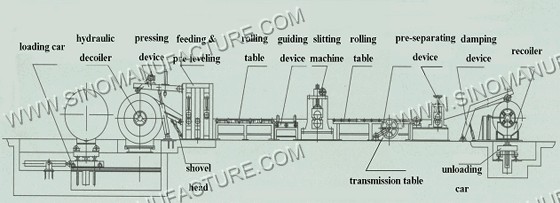

(4—16)×1800mm DECOILING,LEVELING AND CUT-TO-LENGTH LINE I Technical Parameter 1. Thickness range of

coil plate: 4—16mm 2. Width of coil

plate: 900—1800mm; 3. Coil

I.D: ф508mm—ф760mm; 4. Coil

O.D: ф2200mm; 5. Weight of coiled

plate: 30T; 6. Width of hydraulic

shearing machine: 2000mm; 7. Cut-to-length

accuracy: length tolerance: ±1.0mm/2000mm; diagonal tolerance: ±1.5mm/2000mm; 8. Material of flattening

rollers: 40Cr hardness of flattening roller surface: HRC48°—52°; 9. Flattening speed: 0-18

m/min, calculated by 8m plate: 2 pcs/min; 10. Flattening machine adopts auto lubricating

system. II Illustration of main parts of the line 1. Hydraulic loading trolley: loading capacity

of 30T The operation and lifting of this trolley is conducted by hydraulic

oil cylinder. 2. Hydraulic decoiler: Hydraulic expansion, double-cone pushing type, capacity 30 tons. 3. Hydraulic pressing and guiding, shovel-head, pinch and

preliminary flattening device: This is composed of frame-stand, hydraulic pressing and guiding

arm, coil opener, hydraulic shovel-head device, hydraulic pinch and

preliminary flattening device, power device, etc. 1) Hydraulic pressing & guiding device: This is composed of hydraulic pressing and guiding arm, pressing

and guiding wheel (cover by rubber), sprocket wheel, chain, etc.,

driven by 7.5kW decelerating motor:7.5KW. 2) Hydraulic shovel-head device: This is composed of shovel-head body, hydraulic shovel-head,

balancing device for hydraulic shovel-head. 3) Hydraulic pinch and preliminary flattening machine This is composed of slide-stand, pinch rollers (2pcs), hydraulic

pinch device, 2pcs of preliminary flattening rollers, etc. This pinch and pre-flattening machine is of gear & worm driven,

by AC speed-adjustable motor 22kW, decelerator 500. 4. Transitional table 4m This is composed of worktable frame, rolling orbit, bearing-stand,

etc. 5. Centering & guiding machine: This is composed of worktable frame, guiding pole, adjustment

device, moveable plane plate and clutch with multi-roller,

etc. 6. Fine flattening machine: Power part: This is composed of power-stand, 1000 decelerator, direct-current speed adjustable motor:132KW, motor wheel, coupler, YWZ detent, distributing case for

power, universal cross joint, etc. Main machine: This is composed of bottom-stand, frame, under-axle

stand, sliding axle stand, 11pcs of flattening roller (roller

diameterφ200mm),upper pressing frame, up and down supporting wheel stand,

supporting wheel, mechanically lifting & pressing device driven

by two motors: total power 4KW 7. Coding and gauge device, pinch machine for tail plate This is composed of coding transition table, coding device, coder,

pinch machine for tail plate, etc. 8. Cut to length machine: 16×2000mm hydraulic swing-beam shearing machine 9. Worktable, swing pneumatic pinch device This is composed of worktable, frame, rolling orbit, bearing-stand,

etc. driven by decelerating motor: 4KW 10. Unloading dolly: 8m Vertically and horizontally pneumatic pushing device (air

compressor is equipped by buyer themselves) 11. Full set of electric control system This is composed of direct-current cabinet, electric operating

cabinet, operation table for loading, etc. 12. Full set of hydraulic system III Source of main components: 1) Electro-magnetic control overflow

valve and reversing valve

(Shanghai, once licensed by Vickers) 2) Superimposed hydraulic check

valve (Shanghai, once licensed by Vickers) 3) Seal ring of oil

cylinder

Valqua, Japan 4) Direct-current speed adjustable

system

Best brands in China 5) Direct-current

motor

Tongsong Motor 6) Button, approach switch,

photoswitch

Best brands in China 7) Alternative-current contact drive,

cut-out gear Best brands in China 8) PLC

Mitsubishi

from Japan 9) Touch screen

5.7′

Mitsubishi from Japan 10) Coder

1200F/min

Repro, Japan 11) Standard

decelerator

Tailong, Jiangsu, China 12)

Bearing

Harbin bearing, Luoyang bearing, Wa Fangdian bearing

(famous

brands in China) IV Price: Price basis: FOB Shanghai Payment: 30% down payment by T/T in advance, the balance by

irrevocable L/C at sight Lead-time: within 110 days after receiving down payment V Mounting, adjusting and commissioning Relative charges such as visa, round flight tickets, boarding &

lodging, labor charge Euro 100 per day per technician (total three

technicians) will be borne by buyer. The mounting period will be

not more than 30 days if all grounding system are ready. (This is

not fixed because there will be some concrete works during

installation. It should be according to ambient temperature and

your facilities).  |