Guangzhou Huajing Machine Manufacture Co.,Ltd |

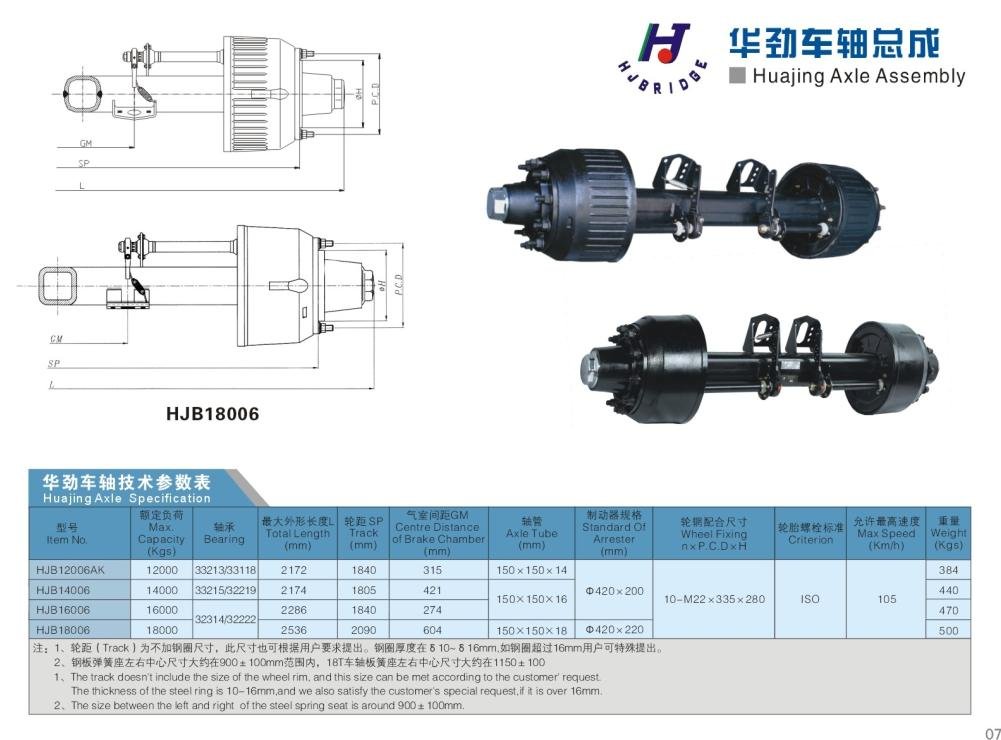

| Use: | Trailer Parts | Parts: | Trailer Axles | OEM No.: | HJB16006 |

| Max Payload: | 16T | Size: | 2286 | Place of Origin: | Guangdong China (Mainland) |

| Brand Name: | HJ | Model Number: | HJB16006 | Rated load: | 16000 kgs |

| bearing type: | 32314/32222 | length: | 2286 | Track: | 1840 |

| air chamber distance: | 274 | Axle tube: | 150*150*16 | Brake size: | 420*200 |

| P.C.D: | 335 | weight: | 470 kgs | wheel rim: | 8.50-20 |

16Ton trailer Axle Assembly with 2 air chamber and decks

prfessional axle factory

15 year experience

ISO 9001/TS16949 CIQ

16Ton trailer Axle Assembly with 2 air chamber and decks

Specifications:

16Ton Axles

BPW axles

10-bolts axle

150*150 square tube

Semi Trailer Axles

16T axles

Germany Axles

Brake Size:420*200mm

track:1840mm

HJ axle is available forBPW axle, widely used as trailer-axle, semi-trailer axle, flatbed axle, dumper axle, dipper axle, oil tank axle, etc. made of high intensity alloy, with high performance, long use life, not easy to distort. Strong, over-loading capacity. TS16949ISO9001:2000 certificated. enjoying a good reputation from both domestic and abroad customer due to our good quality of products , competitive price and best after-sale service. Welcome to inquiry!

About Us:

Name: Guangzhou Huajing Machine Manufacture Co.,Ltd

Address:Lanyuan road Zhaidong Xintang town,Zengcheng Guangzhou province, China

Year of establishment: 2002

Company type: professional trailer parts manufacturer

Employees: around 700

Areas: 250,000 square meters & 8 modern workshops

Certificates: ISO9001;TS16949

200,000 sets of axle assembly; 20,000 sets of suspension; 1 million sets of brake shoes and other parts

Our products as follow:

Wheel rim:Tube type , different size for truck, semi-trailer

Axle:American type & German type with different capacity.

Leaf Spring:Conventional and parabolic type with different size.

5th wheel & King pin:2'' & 3.5'', Forging type

Suspension:1axle, 2axle & 3axle with different steel plate thickness, Bpw type,American type

Air Suspension:1axle, 2axle & 3axle with or without lifting

Bogie:24tons, 28tons, 32tons,drum and spoke type

Landing Gear:Gear outside & Gear inside with capacity 25tons, 28tons, 30tons

and 35tons

Air Chamber:T14, T16, T24, T30, T24T30, T24T24, T30T30

Brake shoe:420*180,420*200,420*220

Drake drum:12T ,14T,16T,18T etc.

Slack adjuster:manual and automatic slack adjuster

Production line:

1. All the equipments of Germany type axle production line adoptdigital technique.

2.The axle assembly line adoptautomatic painting lineand assembly line.One axleassembly can be finished in 90 seconds

3.Automatic founding production linehave PLC automatic device and mechanized production line, producing drum, hub and so on.

4.Pressing production linehave 25T to 800T pressing equipment, controlled speed device, integrated unit automatic gas-welding machine and automatic electrophoretic flow line, producing dust covers, brake shoes, suspensions and so on.

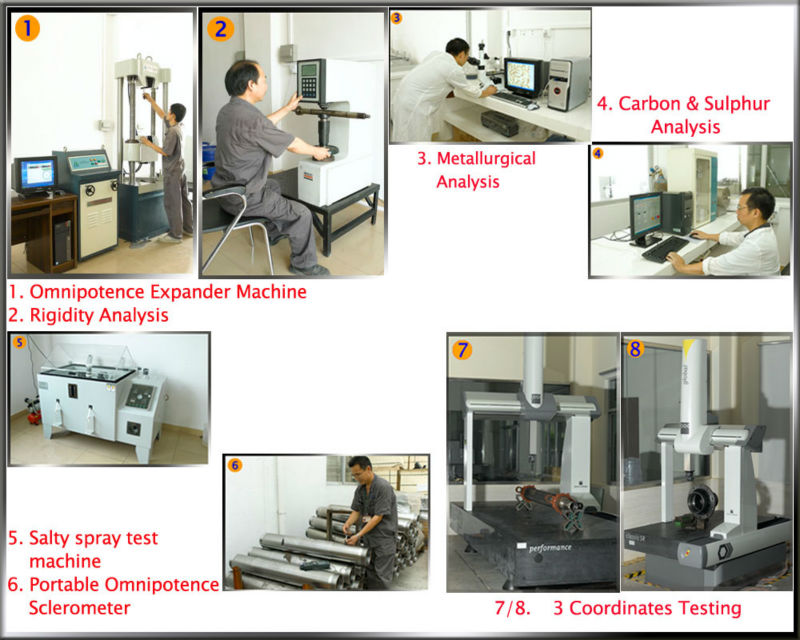

5.Quality Control:spectral analysis, Omnipotence expander machine, Omnipotence expander machine, Fatigue test machinery, Salt spray test machine, Metallurgical analysis, Rigidity Analysis etc.

Advantages of HJ axle:

1.HJ Germany Bpw axle spindle, made of alloy material, is processed by digital control lathe. Bearing position is under intermediate frequency, wear-resisting.

2.HJ Germany axle brake lining is non-asbestos, with long service life.

3.Use famous brand grease, with high lubricating performance and efficiency.

4.Famous brand bearing for axle, with good loading capacity, high rotating speed, good intensity,abrade resistant and heat resistant.

5.Axle brake drum use HT250 material, high-temperature resistance, stable, good performance of tensile strength, shock absorption

6.Axle wheel hub use QT450-10 material, high-temperature resistance, wearing-resistance, good bearing capacity

7. Use double side single hole boring lathe and double side three hole boring lathe, which process the both side of axle body at the same time to insure the axle concentric.

8.Axle hub bolt are made of alloy material, which has the capacity of high intensity, well stretch& bends intensity.

9.HJ axle spare parts are processed by digital equipment, complied with the international standards, which can be exchanged with the original BPW spare parts.

10. HJ axle designed according to international standards, ABS system is alternative, aslo can assemble ECO hub system

11.Special design for customer

After-sales service:

--We guarantee that, under normal use,all defective axle can be repaired and changed for free(except easy wearing parts) .The guarantee period of axle tube is3years.

--0ur company holds the notice all the time"frist -class goods,reasonable price