Henan Mind Machinery Equipment Co., Ltd. |

|

| Model | Grinding Roller | Mill Roll Size | Size and Height of Grinding Ring | Max. Inlet Size | Discharging Size | CapacitY | Power | Weight | Size |

| PCs | (R×H)mm | (mm) | (mm) | (mm) | (t/h) | (KW) | (t) | (mm) | |

| 4R3216 | 4 | 320×160 | 970×160 | 25 | 0.2-0.044 | 1.8-4.5 | 37 | 15 | 6900*5800*6580 |

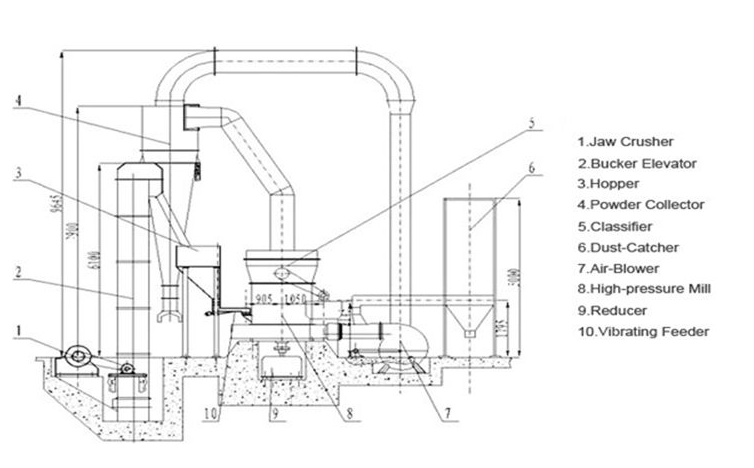

1. The three-dimensional structure of Raymond mill has a small footprint and a complete set of components. From block to finished powder, it is a self-contained production system.

2. The fineness of the finished powder is uniform, and the screening rate is 99%, which is difficult for other milling equipment.

3. The main gear of the mill main machine adopts a closed gear box and pulley, which makes the transmission stable and reliable.

4. The important parts of Raymond mill are made of high-quality steel, and the wear parts are made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

5. The electrical system adopts centralized control, and the grinding workshop can basically realize unmanned operation and convenient maintenance.

Pre-sale service:

1. Instruct customers to choose the most suitable equipment model.

2. Can manufacture products according to special requirements.

In-sale service:

1. Professional and technical personnel install the distribution

before the goods are issued.

2. The product is strictly inspected before delivery and delivered

according to the contract.

After-sales service:

1. Equipment commissioning, operation, training operators.

2. Engineers available to service machinery overseas.

Delivery Time | a. If stock machine, we can send out your products within 5-7 days after receiving clients’ payment. b. If you need special molds or customized production line, the delivery time according to you machine quantity, but we will send out as soon as possible. |

| Payment Terms | T/T, L/C, D/P, D/A, Escrow, Paypal, Western Union |

Package | a. If you order single machine, it can be packed in one wooden

case. b. If you order more machine or a production line, a 20 feet container or 40 feet container |

Quality Guarantee Terms | a. Quality guarantee term is for one year. b. Malfunctions which are caused by machineself and quality will be responsible for our manufacturer. c. Other malfunctions which are caused by operation mistakes, man-made problems, etc will be responsible for clients-self. |