Henan Mind Machinery Equipment Co., Ltd. |

|

| Model | Grinding Roller | Mill Roll Size | Size and Height of Grinding Ring | Max. Inlet Size | Discharging Size | CapacitY | Power | Weight | Size |

| PCs | (R×H)mm | (mm) | (mm) | (mm) | (t/h) | (KW) | (t) | (mm) | |

| 3R1510 | 3 | 210×150 | 650×150 | 15 | 0.2-0.044 | 0.4-1.8 | 15 | 3.8 | 4100*3300*4500 |

| 3R2615 | 3 | 260×150 | 780×150 | 15 | 0.2-0.044 | 0.8-2.5 | 18.5 | 4.2 | 5650*3305*5950 |

| 3R2715 | 3 | 270×150 | 830×150 | 20 | 0.2-0.044 | 0.9-2.8 | 22 | 4.8 | 5600*3400*5900 |

| 3R3016 | 3 | 300×160 | 880×160 | 20 | 0.2-0.044 | 1.2-3.2 | 30 | 6 | 5600*4100*5200 |

1. Grinder type: Ultrafine Mill

2. Application area: micron powder producing.

3. Grinding material: middle and low hardness, moisture below 6%,

and the material should be non-explosive and non-flammable, such

as: calcite, chalk, limestone, dolomite, kaolin, bentonite,

steatite, mica, magnetite, iolite, pyrophillite, vermiculite,

meerschaum, attapulgite, diatomite, barite, gypsum, alunite,

graphite, fluorite, phosphate ore, potassium ore pumice, etc.

4. Capacity: 0.5-25t/h (can be customized)

5. Max feeding size: 20mm (can be customized)

6. Final size (mesh): 325-2500(can be customized)

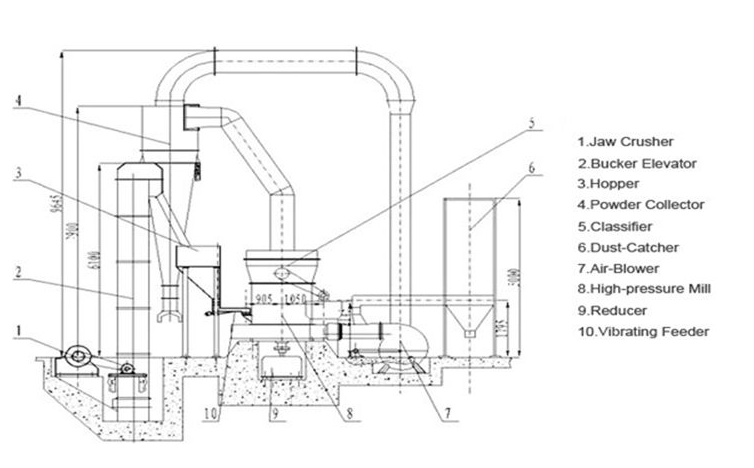

The structure of the Raymond mill is mainly composed of a main machine, an analyzer, a fan, a finished cyclone separator, a fine powder cyclone separator and a duct. Among them, the main body is composed of a frame, an inlet volute, a blade, a grinding roller, a grinding ring and a cover.

1. During the application of our raymond grinding mill, some personnel shall be arranged to take responsibility of management from beginning to end. The operators must be qualified with the required technical knowledge of opreating grinding mills. Before the installation of this grinding mill, the persons related to the operation should receive technical training and fully understand the operating principle, performance and regulations of the raymond mill.

2. In order to guarantee the raymond mill in a normal working

state, a Safety Operation System for the Maintenance of the

equipment must be established. Only in this way can the raymond

mill be guaranteed to have a long-term and safe operation.

Meanwhile, it is necessary to have the required repairing tools,

lubricant and grease, spare parts and accessories during the

operation.

3. After some period of running, the raymond mill should receive an

examination and repairing. The components vulnerable to worn out,

such as grinding roller, grinding ring, relieving tool etc. should

be repaired or replaced. Before and after the operation, a careful

examination should be carried out for the connecting screws, bolts

and nuts on the grinding rollers so as to find whether they are

loose or sufficiently lubricated.

4. When their application time surpassing about 500 hours, all the

rolling bearings in the roller sleeves of raymond mill must be

cleaned, and the damaged parts should be replaced. The oiling tool

can be either a manual oiling pump or grease gun.