BH Mortar Industrial Co., Ltd. |

|

Beautiful design and quality and quantity assured BH sand crusher

Description:

The sand making machine is also called impact crusher and sand making machine. It is suitable for the crushing and shaping of soft or medium hard and extremely hard materials. It is widely used in various ores, cements, refractories, aluminum clay clinker, corundum, glass raw materials, mechanism stone materials, gold slag, etc., especially for silicon carbide, silicon carbide, sintered bauxite, sand, etc. Hard and abradable materials are more efficient than other types of crushers. It is suitable for the crushing of soft or medium hard and very hard ore materials with hardness not higher than 320Pa. The sand making machine is widely used in many departments such as large, smelting, building materials, road, railway, water conservancy and chemical industry. The impact sand making machine is an energy-saving device in the current high-efficiency gravel. Widely used in metal and non-metal ore, cement, refractory materials, abrasives, glass raw materials, building aggregates, artificial sand and various metallurgical slag fine and coarse grinding operations, especially for medium hard, special hard and abrasive materials such as Silicon carbide, silicon carbide, sintered aluminum bauxite, magnesia, etc., are superior to other types of crushers. It can be used in combination with hydraulic protection to handle various metallurgical slags. It is suitable for construction sand and gravel for road construction. The utility model has the advantages of simple structure, low cost, stable operation, high efficiency and energy saving, and the material self-lining in the impeller and the vortex crushing chamber greatly reduces the wear parts cost and the maintenance workload, and effectively solves the "iron pollution" in the process of crushing raw materials such as glass. The problem and the "calendar steel" problem in the steel slag crushing process, the ingenious internal airflow self-circulation eliminates the dust dispersion.

Working principle:

Stone-rock: vertical impact crusher material falls evenly vertically from the upper part of the equipment, and part of it enters the high-speed rotating impeller cavity through the distributor and the feeding pipe, and is ejected from the launching port of the impeller under the action of high-speed centrifugal force, and another Partially in the form of an umbrella, the material falling on the circumference of the impeller is shattered by a high-speed impact and crushing. After the materials collide with each other, eddy currents and multiple impact friction fractures are formed in the impeller and the vortex cavity.

Features:

| The material in the impeller and the vortex breaking chamber is self-lined. | The material in the impeller and the vortex crushing chamber directly reduces the wear parts cost and maintenance workload During the production process, the stone material can form a protective bottom layer, and the body is wear-free and durable.

|

Low loss of wearing parts

| It adopts high quality wear-resistant materials at home and abroad and has a long service life. It is made of a special hard and wear-resistant material, which is small in size, light in weight and easy to replace.

|

| advanced spindle design | Unique bearing installation and advanced spindle design make this machine have the characteristics of heavy load and high speed rotation, with fine crushing and coarse grinding function. |

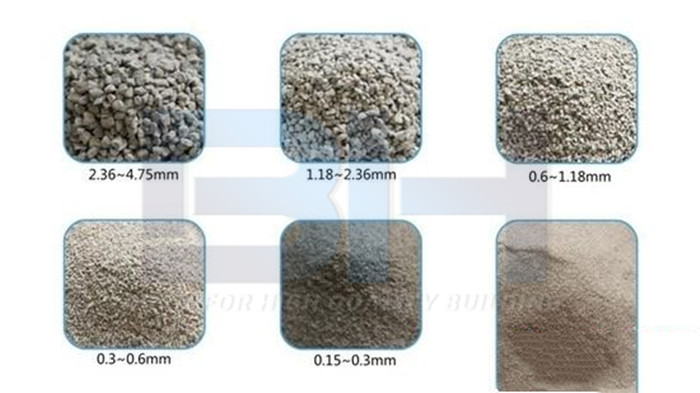

| the finished product is good in grain size | The product is cubic, with high bulk density and low iron pollution. Can be used as a stone shaping machine. |

Application:

The sand making machine is widely used in various medium and fine crushing fields of high hardness and special hard materials such as ore, cement, refractory materials, bauxite clinker, corundum, glass raw materials.