Shaanxi Aipu Solids Control Co., Ltd |

Please check below technical specifications for your reference. And they are is customizable. Please contact us for more details or any question

| Model | Length | Width | Height |

| APGM204 | 2000MM | 2000MM | 200MM |

| APGM205 | 2500MM | 2000MM | 200MM |

| APGM203 | 3000MM | 1000MM | 200MM |

| APGM206 | 3000MM | 2000MM | 200MM |

| APGM209 | 3000MM | 3000MM | 200MM |

| APGM208 | 4000MM | 2000MM | 200MM |

| APGM210 | 4000MM | 2500MM | 200MM |

| APGM212 | 4000MM | 3000MM | 200MM |

| APGM216 | 4000MM | 4000MM | 200MM |

| APGM214 | 5000MM | 2000MM | 200MM |

| APGM215 | 5000MM | 3000MM | 200MM |

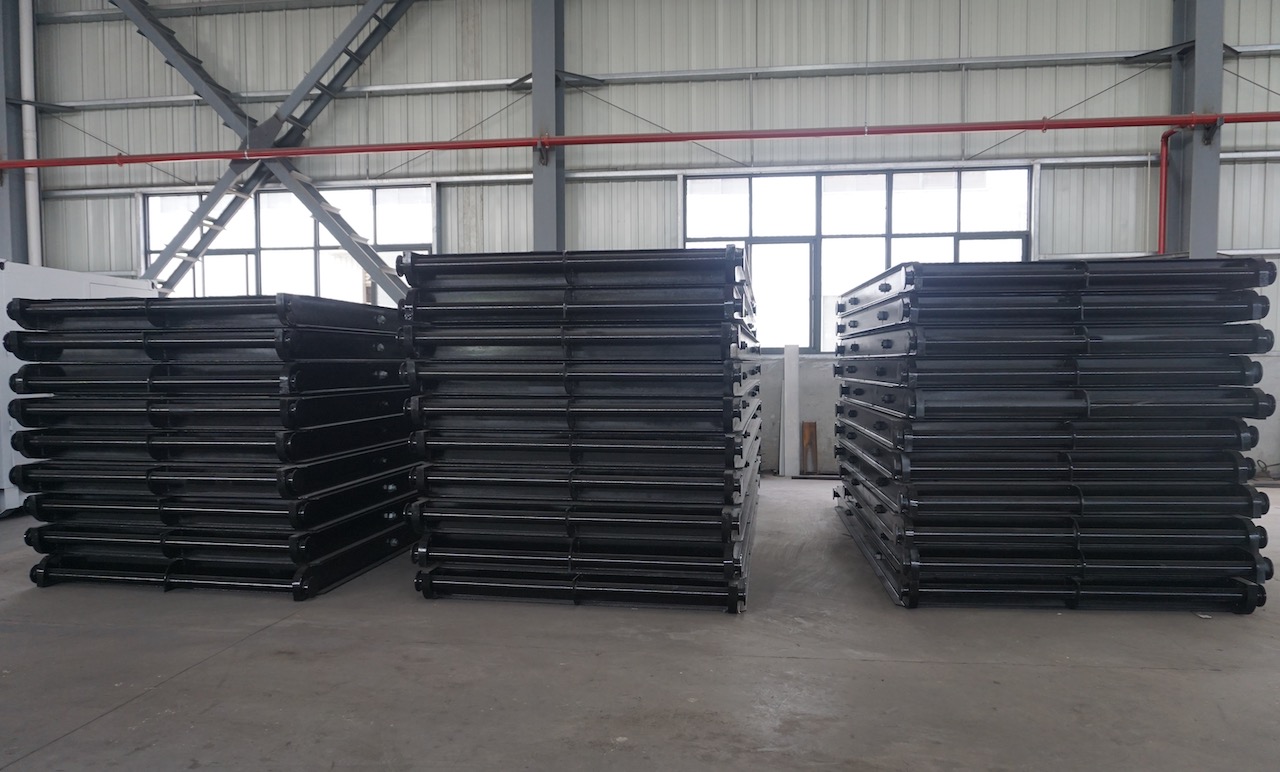

Customized rig matting boards for rigs can be widely used onshore

and offshore. Drilling rig mattings at AIPU Solids are made of

high-quality carbon steel beam and larch wood or conifer wood. And

for almost all of the wood, there is an anti-corrosion process. Or

we process it before inserting it into the steel frame or after.

Drilling rig mats are widely used in oilfield drilling. It’s

a portable platform used to support equipment used in construction

and other resource-based activities, including drilling rigs,

camps, tanks, and helipads. It may also be used as a structural

roadway to provide passage over unstable ground, pipelines, and

more.

We know well drilling is an outdoor activity. Many drilling site

place condition varies from each other. The rig matting

board can help us to get relatively flat ground. Rig matting

board can be a new round or platform. We can put the rig and

solids control system on it for safe condition. According to the

general area of drilling sites we can divide the mats into many

smaller pieces. For example, the total area of request mats is

about 300m². We can use mats sized about 2x1.5m or 2x3m. And

according to loading requirements, we confirm steel beam size and

the wood beam size.

And the rig matting boards can help much on safe working

condition. If the ground evenness is not good the rigs or even

other equipment/units will fall down. For some ground soft, the rig

mat board will provide strengthened support. Why do we need

customized rig matting boards? Because clients or users drill the

well at different places. And individual clients have different

preferences for on-site layout.

There are wood beams, steel beams, mounting bolts, and other

auxiliary parts. Such as the loading log or ring, the strengthened

rod at 2 ends. Usually, we'll use the H beam since the H beam is

more even and easy to fabricate whole rig mattings. The beams

of wood should be inserted into the steel frame made of an H

beam.

The wood beam can be the larch or the conifer. But they both should

be processed as the cuboid beam. And all of the beams used for

rig mattings will be treated for the anti-corrosion effect. This

will help to get strong support and a safe working condition. How

to confirm the rig matting size? Based on the general area of our

working site. Then try to divide all of the rigs evenly with the

same size rig mats.

We have sufficient experience in rig mat board manufacture. We know

how to satisfy the users completely and properly

All rig mats produced by Aipu solids control will be qualified and reliable. We do the following to give users confidence.

1. The raw material. Including the steel and the wood. Selected

strictly according to executive code.

2. Wood will be processed under an anti-corrosion procedure

3. We do the inspection and all processes step by step to ensure

users' high-performance products.

4. Painting the rig mats with famous brand marine coating oil,

which is high anti-corrosive.

5. Custom-built size and design as per clients' demand.

Aipu can produce rig mattings according to clients' certain

requirements. Any demand? Please let us know

The biggest, fiercest machinery calls for the toughest, most stable

platform. Composite and wood rig mats can handle Big Rig

challenges. At AIPU, our rig mats are designed to deal with the

pressure of the heaviest tracked or wheeled machinery.

Combining dense wood and hard steel, wood rig mats provide the

right platform for difficult construction and excavation jobs. Like

our other timber mats, rig mats start with better lumber. A rigid

steel frame is included during the construction process.

Composite rig mats, such as SYSTEM7™, offer a smart way to protect

your equipment and the environment. Willing to work for decades,

AIPU composite rig mats don’t absorb water or chemical spills. They

are lighter to transport and, since they are interlocking, provide

a foolproof way to cover the area.

Whether you choose composite or hardwood, rest assured that AIPU

rig mats can take the most punishing uses. You’ll find AIPU rig

mats across the continent at oil and gas drilling projects, big

construction sites, and more.

For any questions or demands, please feel free to contact AIPU

solids. You will get a free offer on an optimal solution, you will

get a professional proposal very soon.