Kondasin International Co.,Ltd. |

|

Piling Tool Kelly Bar Rotary Machine Tools High Grade Materials

High Durability

The kelly bar is most important for rotary machine therefor it must

be treated with as much careful as the drilling rig,the tool and

bits in order to ensure drilling performance.Kelly bar

are designed for the purpose of transferring torques and pressures

onto a drilling tool.

Interlocking and friction is two types we can provide now,kelly bar

length depends on actual needs of customers or the drilling

machines' parameters.

A kelly bar in a system of drive keys and lock recesses weld onto

their outer surface which has 2-5 telescopic tubular sections.

With High torsional coefficient,the compression and vibration

resistance of kelly bar is higher than average level,high efficient

in rock drilling construction.

In each section,normally kelly bars are matched with a total of 6 drive keys.High grade materials and special welding process guarantee a high durability and wear risistance of our kelly bar.

The key parts of kelly bar like drive key which is widely used heat treatment to improve wear resistance.

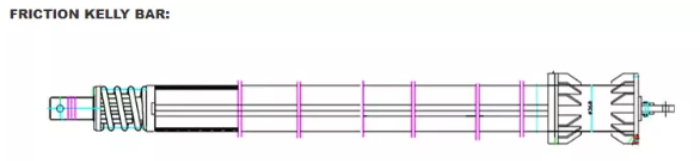

Frictional kelly bar

Friction kelly bar,from its name which means it transfer torque to the drilling tool by friction. The telescopic elements are advanced by using the “frictional contact” from each of the friction drive rails that run down the outside of each kelly bar. These drive rails, on the outside of each kelly bar, are driven by the rotary table and the terminal joints of each successively larger diameter kelly bar. The terminal joint is long piece on the inside and at the bottom of each kelly bar. Friction kelly bars are normally supplied in 4 or 5 telescopic elements as they are mostly used for deep piles in medium hard soil conditions.

This type of the kelly bar is suitable for soft ground and mud, mud, (mud) sand, gravel layers.

Interlocking kelly bar

Interlocking kelly bar are especially designed for drilling into hard materials and when crowd force application is required.Locking kelly bars are provided with drive rails designed with locking pockets on their length and corresponding termina joints locking guides. The purpose is to interlock each telescopic element to the inner following one in order to apply the maximum torque and crowd force developed by the base rig.Therefore the rotary table inner drive is also equipped with locking pockets,. When extracting the locking bar from down the hole, the combination of lifting and rotating counterclockwise will allow the telescopic element to unlock. interlocking Kelly bars are usually supplied with 3 or 4 telescopic elements.

| Name of product | External diameter | Pitch No | Length section | Rated torque | Depth |

| Friction kelly bar | 355 | 4,5 | 10-13 | 180 | 36-60 |

| 377 | 4,5 | 10-14 | 200 | 36-65 | |

| 406 | 4,5 | 10-15 | 210 | 36-70 | |

| 419 | 4,5 | 10-15 | 250 | 36-70 | |

| 440 | 4,5 | 10-15 | 250 | 36-70 | |

| 470 | 4,5,6 | 10-17 | 280 | 36-95 | |

| 508 | 4,5,6 | 10-18.5 | 320 | 36-103 | |

| 530 | 4,5,6 | 10-19 | 380 | 36-106 | |

| 575 | 4,5,6 | 10-21 | 420 | 36-120 | |

| 630 | 4,5,6 | 10-21 | 450 | 36-120 |

| Name of product | External diameter | Pith No | Length section | Rated torque | Depth |

| Interlocking kelly bar | 355 | 3 | 10-13 | 180 | 27-36 |

| 377 | 3,4 | 10-12.5 | 220 | 27-44 | |

| 406 | 3,4 | 10-15 | 230 | 27-57 | |

| 419 | 3,4 | 10-15 | 250 | 27-57 | |

| 440 | 3,4 | 10-15 | 250 | 27-57 | |

| 470 | 3,4 | 10-17 | 280 | 27-65 | |

| 508 | 3,4 | 10-17 | 320 | 27-65 | |

| 530 | 3,4 | 10-20 | 380 | 27-76 | |

| 575 | 3,4 | 10-21 | 420 | 27-80 | |

| 630 | 3,4 | 10-21 | 450 | 27-80 |

1. The advantages of our Kelly bar, such as low weight, high strength,

high abrasion-resistance, high-reliability are safeguarded.

2. Main body made of alloy hot-treated specially enjoy both high hardness and

perfect welding performance, high abrasion-resistance leads to

high-reliability.

3. Heat treatment is widely used in the key parts such as drive key

to improve wear resistance

4. Small clearance and high-precision mating of the drill pipe ensure

its good working order and service performance.

5. Fulfill the rotary drilling rig full torque operation.

Kelly bars is to transfer to the drilling tools both the torque and

the pressure produced by the drilling machine,it candrill in dense sand and gravel and weak to strong rock.