Suzhou Energy Tool Co., Ltd. |

|

Verified Suppliers

|

|

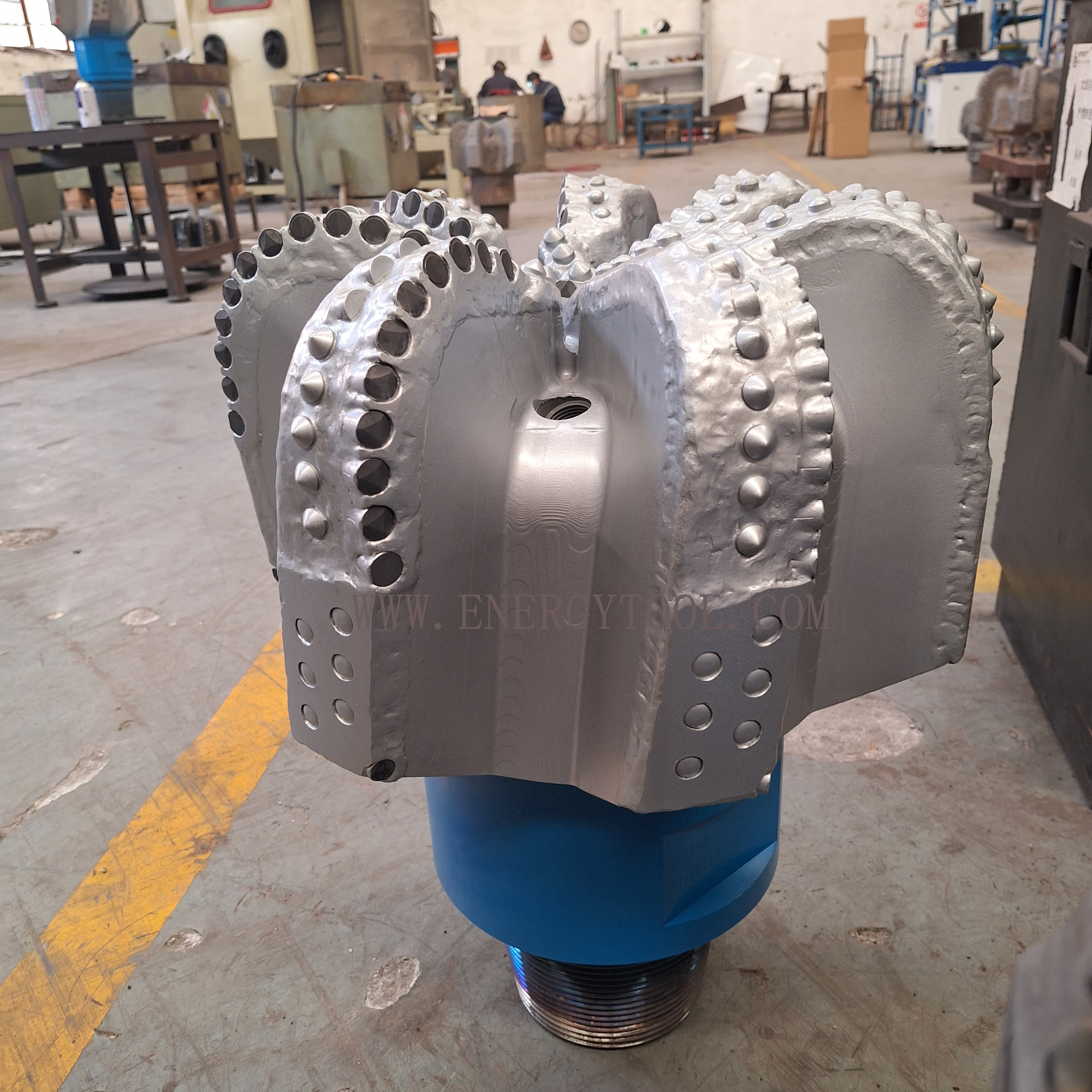

Diamond Drill Bit 17-1/2inch 6 Blade PDC Drilling Bit of API Spec

1 . Descriptions:

PDC bits are specifically engineered for high-speed drilling in shale, limestone, and sandstone formations. Diverging from roller cones, these polycrystalline diamond compact (PDC) drill bits are solid bodies without any movable components. The fixed-cutters efficiently scrape away the rock, enabling more efficient operation at higher rotation speeds, particularly in consolidated formations.

2. Specification:

Polycrystalline diamond compacts PDC bit in the Oil and Gas Industry PDC bits get their name from the polycrystalline diamond compacts used for their cutting structure. A PDC bit is a drill bit fitted with industrial diamond cutters instead of hardened metal teeth.

| BIT DESIGN | |

| size | 17-1/2inch |

| IADC Code | S333 |

| Body type | Steel Body |

| Blade Count | 6 |

| Primary Cutter Size | Ф16 mm |

| Gage Cutter | Ф16 mm |

| Nozzles | #10*5 |

| Gauge Length | 3.5" in |

| API Connection | 7-5/8REG |

| Weight | 228KG |

| OPERATIONAL PARAMETERS | |

| Weight on Bit (KN): | 66-198 |

| RPM Range(Rotary): | 100- DHM |

| Flow Rate(lps): | 28- 39 LPM |

| Make-Up Torque(KN): | 900-1200KN.M |

3 . Tricone Bit profile

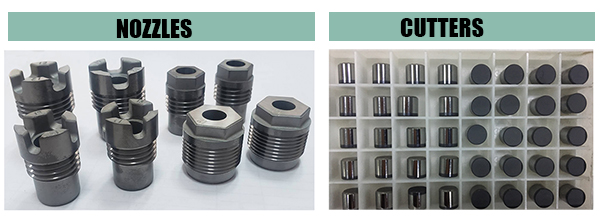

4 . Drill Bit PDC Cutters

Polycrystalline Diamond Composite (PDC) cutters are the main point

of contact for a drill bit. PDC bits remove the rock mainly by

shearing.

The PDC cutters are exposed to a lot of heating and cooling down

the well, a very challenging environment.

PDC cutters that have lower thermal degradation and more thermal

stability generally achieve higher ROP and increased wear

resistance. So, optimizing the cutter is important.

5. Drill Bit Nozzles

Drill bit nozzles help clear the cutting area and cool the

Polycrystalline Diamond Composite (PDC) cutters.

Effective placement of these nozzles along with the angle they are

set at plays a critical role on how efficient the drill bit

performs.

Fluid channels also complement nozzle placement to imp