Saint Best Group Limited |

|

| Packaging Details: | 1.Simple stretch film packaging; 2.Professional export wooden packing for China aluminium profile cnc drilling and milling machine |

|---|---|

| Delivery Detail: | Shipped in 15 days after payment |

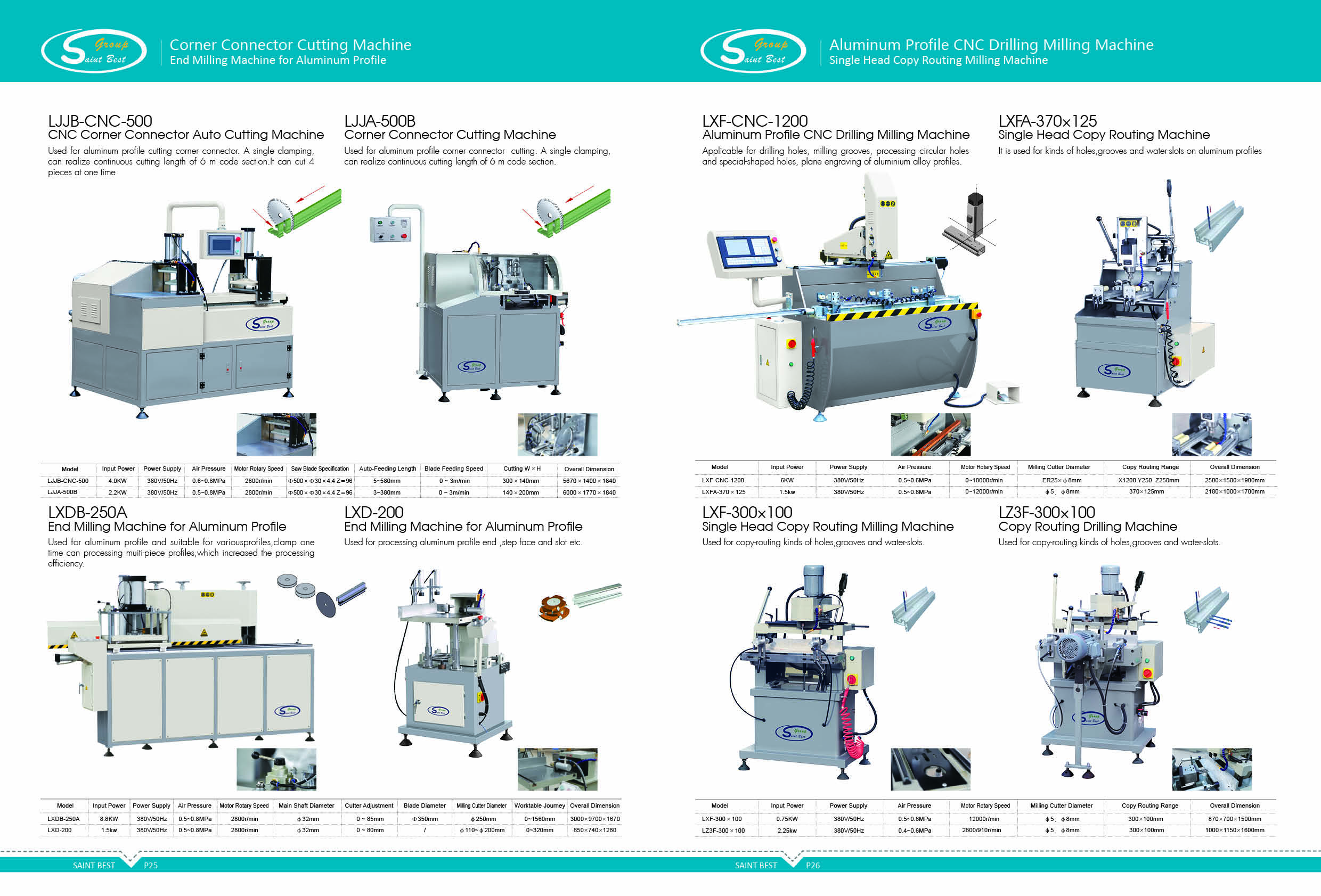

CNC Automatic Milling and Drilling Machine for Aluminum Profile / Automatic CNC Drilling Machine for Curtain Wall

Specifications:aluminium profile cnc drilling and milling machine1.Used for aluminum and PVC profiles all kinds of holes drilling |

Equipment Features

--Milling aluminum profile at different sixe hole and groove.3200mm aluminum CNC milling machine

--Adopting ball bearing movement device, high precision guide liner

rack and pinion, servo motor, ensures the stable movement with high

precision position and operation.

--Adopting imported high speed main axis motor, stable rotation,

low noise, strong milling ability.

--Intelligent integrated CNC system, concision and vivid human and

machine interface, easy operation.

Main Specification and Technical Parameter

| X-way journey | 3200mm |

| Y-way journey | 300mm |

| Z-way journey | 300mm |

| X-axis speed | 0-60m/min |

| Y-axis speed | 0-15m/min |

| Z-axis speed | 0-15m/min |

| Main axis rev./ power | 18000r/min |

| Worktable work position | -90° 0° 90° |

| Clamp | ER25-Ф8 |

| Air supply | 0.5-0.8Mpa |

| Power supply | 382v 50Hz |

| Total power | 6ke |

| Quantity of clamp | 6 |

| Clamp station/ journey | 2/50mm |

| Processing size | 160 x 160x 3200mm |

| Overall dimension | 4400 x 1500 x 1800mm |

| Weight | 1200kg |

Equipment Configurations

1.Spindle motor: Italy HSD high speed manual tool changing spindle

2.High quality carbon structural steel welding + casting frame: thermal aging stress treatment, precision machining

3.Guide rail: X, Y, Z axis are using high precision linear guide rail

4.Y, Z axis transmission: high precision ball screw drive

5.Working fixture: 2 sets of pneumatic clamping fixture, the two working areas of the workpiece on the interactive

6.Drive system: a full digital AC servo drive system

7.Spray cooling system: can be used together with the processing procedures

8.Professional industrial control operating system

9.Manual pulse generator, convenient for alignment and measurement of processing origin

10.Program: can be online or offline programming

| Main Accessory |

| PLC | SIEMENS, OMRON,Taiwan Delta |

| Solenoid valve | Germany FESTO |

| Electrical Button and Switcher | Schneider |

| Temperature Controller | OMRON |

| Motor | DEDONG Zhejiang |

| AC Contactor and Circuit Breaker | Schneider |

●Free contact for the most suitable machine

●Free professional design for each customer especially.

●24 hours technical support by phone, email or skype

●1years warranty period

●Our senior engineer is available to travel aboard, help the

installation, maintenance and training staff.

Saint Best Group Factory Details:

+ Our factory has two large fabricating factories;

+ Our factory has our own office building and staff apartment;

+ Our factory has 25 fabricating workers which have more than 10 years window door and insulating glass fabricating experience;

+ Any more details, welcome to contact us our customer service department at any time on line.

WHY YOU CHOOSE US Question AND Answer

1.Question:Are your manufacture?

Answer:

We are manufacture of the PVC/UPVC/Plastic/Vinyl window door machine, Aluminum window door machines, Insulating glass machines.

2.Question:What’s the customer service?

Answer:

1).Reply within 12 hours.

2).One to one service.

3).24 hours for after-sale service.

4).More than 15 years experience in this field.

5).Fluent English, communication barrier free.

3.Question:What’s the guarantee?

Answer:

1).Our guarantee for 2 years.

2).24 hours technical support by email or calling.

3).English manual and video tutorial.

4).2 years quality guarranty for the machine (excluding the consumables).

5).We will provide the consumable parts at an agency price.

6).24 hours on line service each day, free technical support.

4.Question:If your price is higher than another company or factory?

Answer:

Please check, what is is the difference of the machine parts, service and guarantee, especially the machine inner electric parts, sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, we use the world famous brand parts to install to machines inner, so that can sure you can use the machines very long long years. We believe that you will choose the true quality long lifetime machine, not cheaper machine.

5.Question:How long is the delivery time?

Answer:

For standard machines, it will take 1-15 days. (Some machines, such as the lock hole milling machine, end milling machine or glass edge polishing machine or butyl extruder machine etc., these common models machines, if you buy separate machine, we can delivery within 1-7 days after get your deposit, it depends on different model; If your order machines are enough a container to load or you order the whole production line machines, we can delivery within 10-15 days.)

For non-standard machines and customized machines according to clients specific requirements, it will take 15 to 30 days. (If the machines that customer ordered are very special, we will take long time to make the machine specially, it will take 15-30 days, this point hope customer can understand, thanks!)

6.Question:How's the payment?

Answer:

1).Telegraphic Transfer. T/T: 30% T/T deposit, 70% rest balance before shipment or against the original BL scanning. (If customer want to pay little deposit in beginning, for example, some customer want to pay 10% deposit, it is also acceptable; If some customer visit our factory and confirm the order, want to pay some cash as deposit, it is also acceptable).

2).If you want by Western Union or Trade Assurance, it is also OK.

7.Question:What is SAINT BEST GROUP special advantage?

Answer:

We have skilled engineers with well English ability in this field about 20 years, they can directly to give you any help on machines by calling or by video link or by email in short time. Before our machine reach your workshop, if you need we help you to design the drawing that list all machines should how to place in your workshop, we can help you to make the drawing to give suggestion in short time; And if you need we suggest how many squaremeters workshop is betterr, you can tell us your plan production, then we will suggest how many machines you need, and tell you how many squaremeters workshop is better.

8.If I want to use some certificates to pay less tax for importing your machines, can you help me?

Answer:

Our company can make the different Certification of Origin, it will make you to pay the less tax if you import our machines.

Contact Us

Contact Us

If you are window fabricator, looking for Aluminum profile CNC Milling and drilling machine,

If you have interest to set up window production line as your new business,

Or you have any questions about window machine,